Vinyl chloride-based film for food packaging

A technology of food packaging and vinyl chloride resin, which is applied in packaging, wrapping paper, transportation and packaging, etc. It can solve the problems of damaged appearance, poor appearance, difficulty in providing appearance food packaging film, etc., and achieve excellent safety and excellent appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

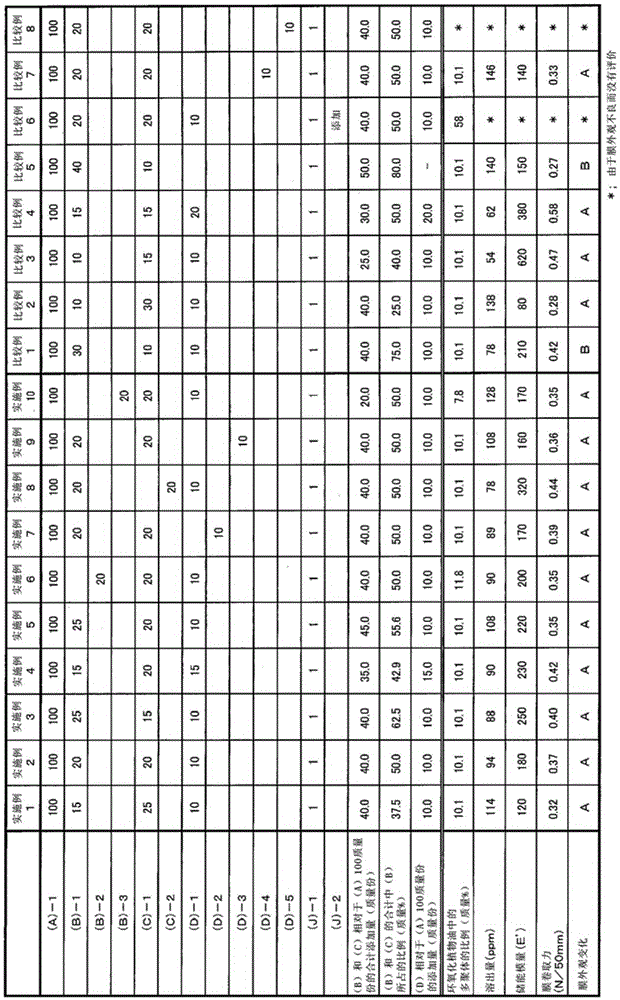

[0103] Put into the super mixer at the ratio of (A)-1100 parts by mass, (B)-115 parts by mass, (C)-125 parts by mass, (D)-110 parts by mass, and (J)-11 parts by mass, while stirring While raising the temperature of the material from room temperature to 130°C, after heating and mixing, it was taken out at the time of cooling to 70°C to obtain a resin composition.

[0104] The obtained resin composition was extruded and molded with a Φ40 mm single screw extruder (L / D=20) equipped with a T die (width 350 mm, gap 0.4 mm) at a resin temperature of 200°C to obtain a film with a thickness of 0.01 mm. The obtained film was evaluated for the ratio of the polymer in the modified epoxidized vegetable oil, dissolution properties, flexibility, film roll-up properties, and changes in film appearance.

[0105] The results are shown in Table 1.

Embodiment 2

[0107] A film was produced in the same manner as in Example 1, except that (B)-1 was 20 parts by mass and (C)-1 was 20 parts by mass in Example 1. The same evaluation as in Example 1 was performed, and the results are shown in Table 1.

Embodiment 3

[0109] A film was produced in the same manner as in Example 1, except that (B)-1 was 25 parts by mass and (C)-1 was 15 parts by mass in Example 1. The same evaluation as in Example 1 was performed, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com