Leached rice cooker

A technique for draining and draining rice, applied in the field of rice draining, which can solve problems such as difficult cleaning, uneven heating of rice, and difficulty in steaming, etc., and achieves the effects of easy cleaning and maintenance, avoiding solenoid valves, and good rice cooking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

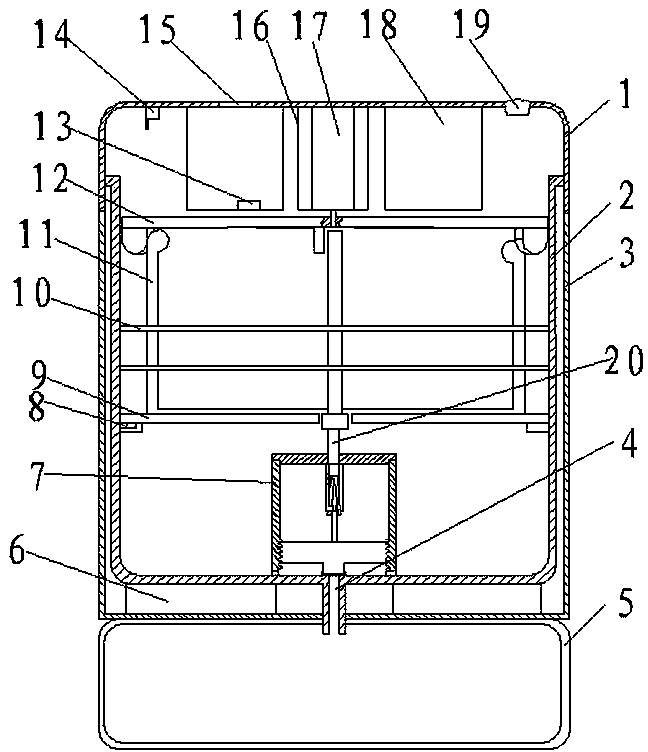

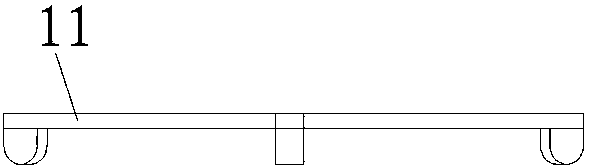

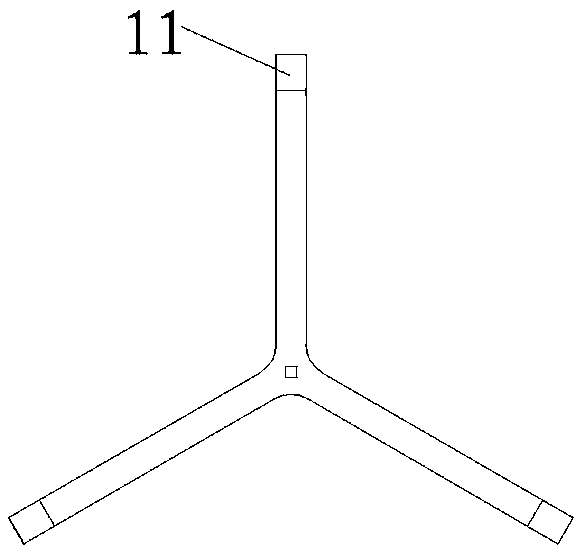

[0045] Such as figure 1 As shown, a rice cooker includes a shell, a bowl 2 and a rice soup tank 5, the bowl 2 is arranged inside the shell, and a heating mechanism 6 is provided between the bottom of the bowl 2 and the shell (in this embodiment is a ring-shaped heating resistor), the rice soup tank 5 is detachably arranged at the bottom of the shell, and the bottom of the bowl body 2 communicates with the rice soup tank 5 through the drain flow channel 4 (the drain flow channel 4 extends from the bottom of the bowl body 2 to the outside through The shell enters the rice soup tank 5, and the inlet of the drainage channel 4 is located on the inner end surface of the bowl body 2); the bowl body 2 is provided with a rice draining plate 9 with a water filter seam 21 (the gap between the water filter seam 21 Smaller than the particle size of rice grains, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com