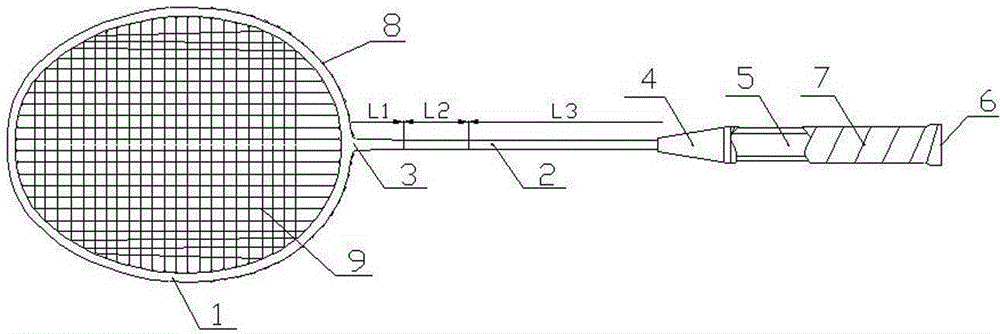

Badminton racket rod and manufacturing method thereof

A badminton racket and consistent technology, applied in the field of badminton racket rods and their manufacturing, can solve the problems of slow hitting speed, long time for racket surface recovery, poor energy storage capacity of racket rods, etc., and achieve the improvement of elastic recovery speed and rebound. Excellent performance and reduced vibration feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

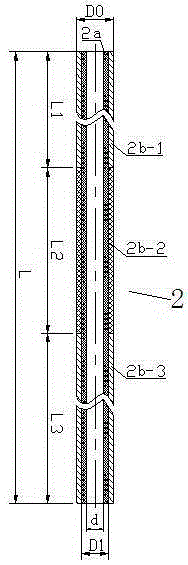

[0102] The following will be combined with figure 2 And specific embodiments (taking φ7.0*φ4.0*295 racket as an example), the present invention is further described:

[0103] 1. Hollow cylindrical body 2a

[0104] 1. Cut the carbon fiber composite material prepreg containing epoxy resin into the required size.

[0105] The specifications and dimensions of the carbon fiber composite material prepreg in this embodiment are:

[0106] (1) Angle 45 degrees: FAW (carbon fiber) is 125g / 2 m, the length is 315mm, the width is 79mm, and the quantity is 2 pieces;

[0107] (2) Angle 0 degrees: FAW (carbon fiber) is 125g / 2 m, the length is 315mm, the width is 50mm, and the quantity is 1 piece;

[0108] The carbon fiber composite material prepreg used in this embodiment is a commercially available high-quality product, the carbon fiber composite material prepreg is produced by SK company, the carbon fiber models are M40J and UTS50 respectively, and the weight ratio of the epoxy resi...

Embodiment 2

[0172] The following will be combined with figure 2 And specific embodiments (taking φ7.0*φ4.0*295 racket as an example), the present invention is further described:

[0173] 1. Hollow cylindrical body 2a

[0174] 1. Cut the carbon fiber composite material prepreg containing epoxy resin into the required size.

[0175] The specifications and dimensions of the carbon fiber composite material prepreg in this embodiment are:

[0176] (1) Angle 45 degrees: FAW (carbon fiber) is 125g / 2 m, the length is 315mm, the width is 79mm, and the quantity is 2 pieces;

[0177] (2) Angle 0 degrees: FAW (carbon fiber) is 125g / 2 m, the length is 315mm, the width is 50mm, and the quantity is 1 piece;

[0178] The carbon fiber composite material prepreg used in this embodiment is a commercially available high-quality product, the carbon fiber composite material prepreg is produced by SK company, the carbon fiber models are M40J and UTS50 respectively, and the weight ratio of the epoxy resi...

Embodiment 3

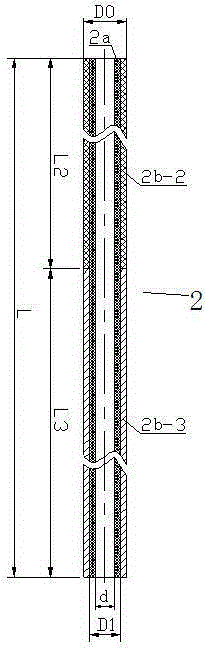

[0242] The following will be combined with image 3 And specific embodiments (taking φ6.8*φ3.6*295 racket rod as an example), the present invention is further described:

[0243] 1. Hollow cylindrical body 2a

[0244] 1. Cut the carbon fiber composite material prepreg containing epoxy resin into the required size.

[0245] The specifications of the carbon fiber composite material prepreg in this embodiment are:

[0246] (1) Angle 45 degrees: FAW (carbon fiber) is 125g / 2 m, the length is 315mm, the width is 78.5mm, and the quantity is 2 pieces;

[0247] (2) Angle 0 degrees: FAW (carbon fiber) is 125g / 2 m, the length is 315mm, the width is 49.5mm, and the quantity is 1 piece;

[0248] The carbon fiber composite material prepreg used in this embodiment is a commercially available high-quality product, the carbon fiber composite material prepreg is produced by SK company, the carbon fiber models are M40J and UTS50 respectively, and the weight ratio of the epoxy resin conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com