Multifunctional turned-edge projection cutter

A cutting machine, multi-functional technology, applied in the field of multi-functional curling projection cutting machine, can solve the problems of high labor intensity, high risk of injury, slow speed, etc., to reduce labor intensity, enhance competitiveness, and simple operation procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

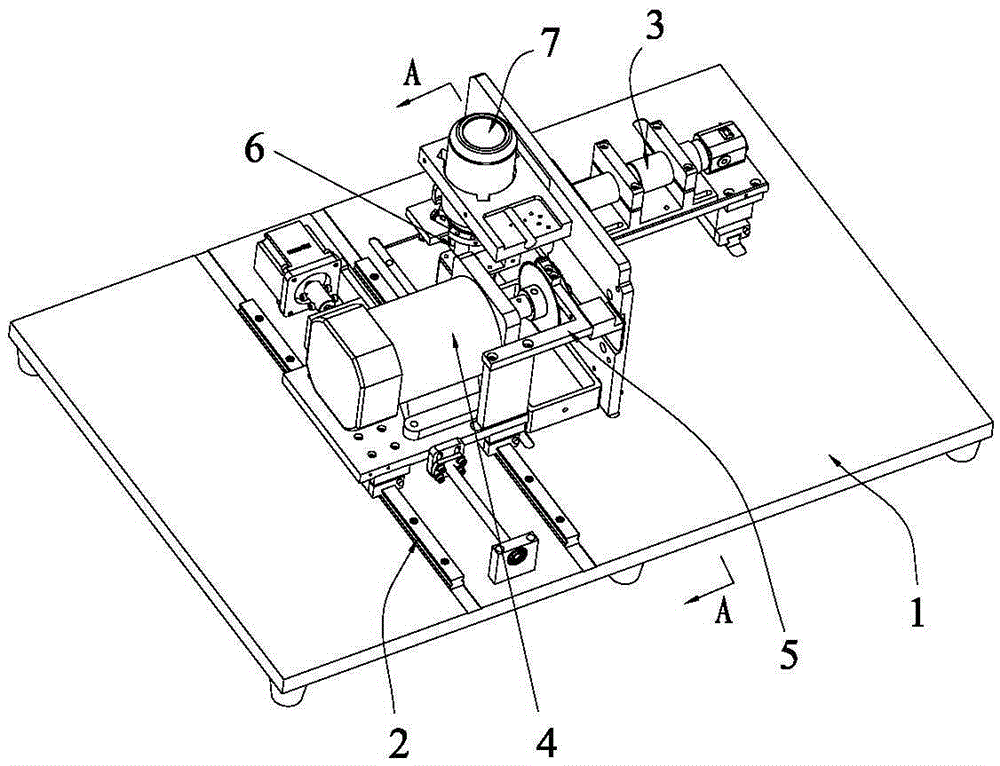

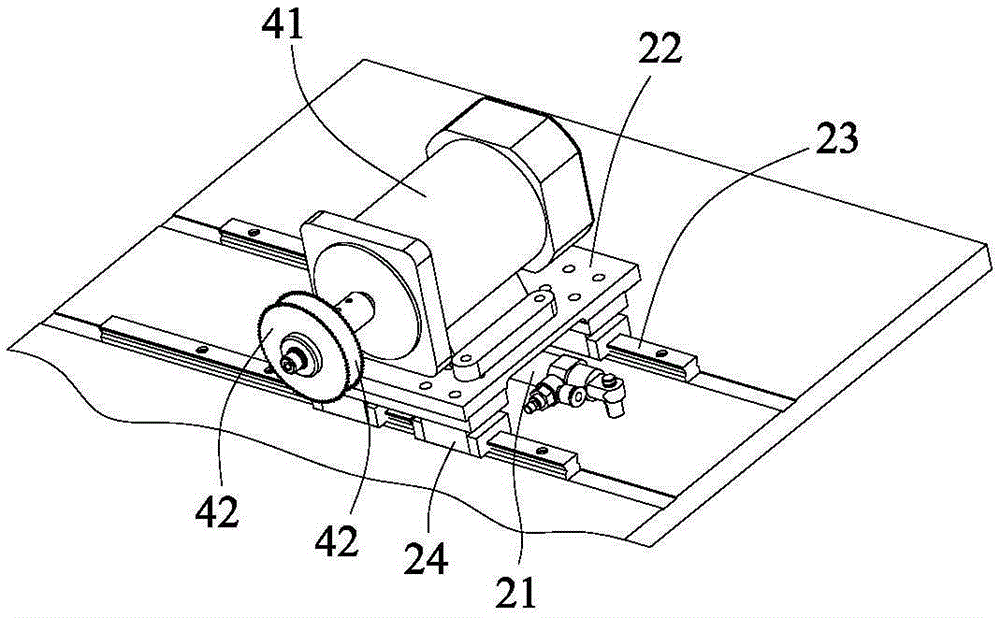

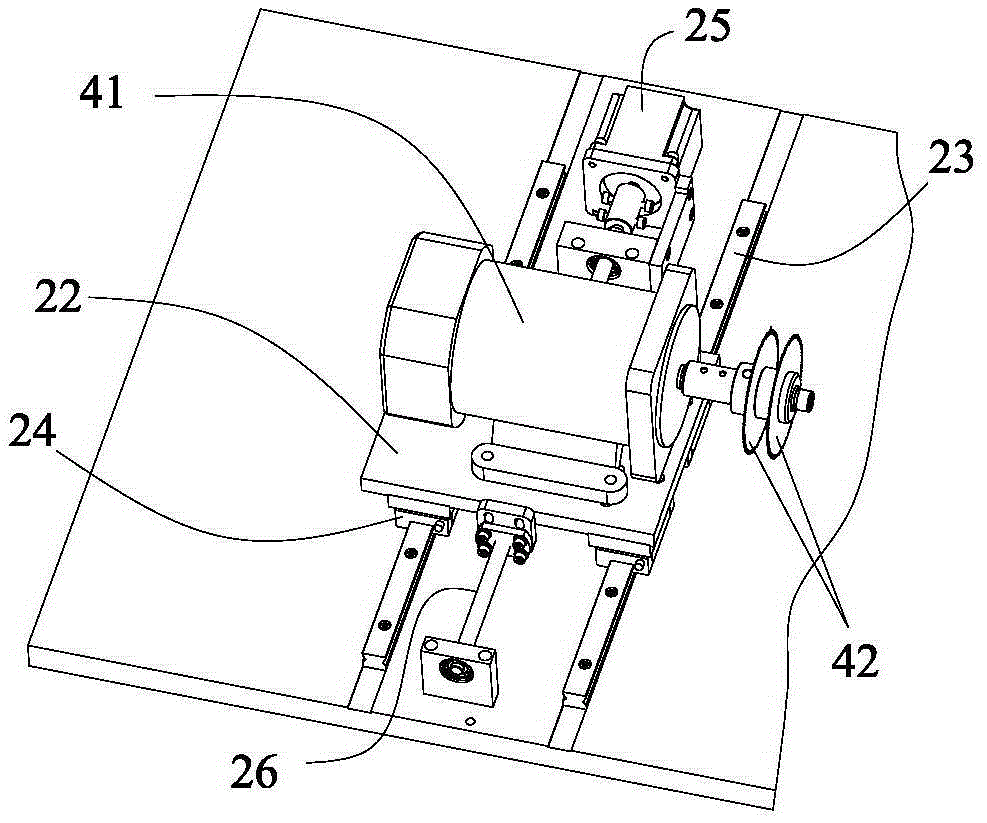

[0025] Example: see Figure 1 to Figure 8 , a multifunctional crimping projection cutting machine provided by an embodiment of the present invention, which includes a bottom plate 1, a linear feeding mechanism 2, a projector 3, a cutting device 4, a linkage crimping frame 5 and a sample tank holding device 6, the The sample tank clamping device 6 is arranged on the base plate 1, the linear feed mechanism 2 is arranged on one side of the sample tank clamping device 6, the cutting device 4 is arranged on the linear feed mechanism 2, and is subjected to the linear feeding mechanism 2. The drive of the feed mechanism 2 moves toward the sample can holding device 6 to cut the sample can 7 on the sample can holding device 6, the linkage crimping frame 5 is arranged on the cutting device 4, and After the cutting device 4 cuts the sample tank 7, it can be pressed on the cutting opening of the sample tank 7, and the projector 3 is arranged on the bottom plate 1 corresponding to the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com