A kind of ultra-high temperature soft core forging method of steel ingot

An ultra-high temperature, steel ingot technology, applied in the field of steel forging, can solve problems such as the inability of alloy steel, achieve the effects of reducing heating times, eliminating shrinkage cavity porosity, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

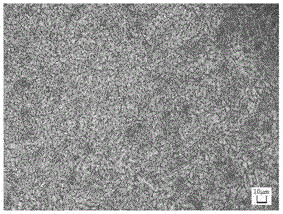

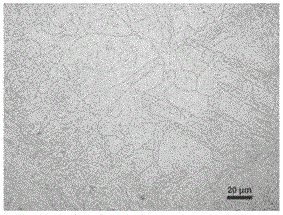

Image

Examples

Embodiment 1

[0059] The weight of the smelted and poured steel ingot is 9 tons, the cross section is rectangular, the size is 720×1080×1450mm, and the material is H13 steel. The measured composition is shown in Table 1.

[0060] The chemical composition (weight percent, %) of H13 steel in the embodiment 1 of table 1

[0061] element C Si mn P S Cr Mo Ni V Fe Measured ingredients 0.38 0.93 0.37 0.012 0.002 5.34 1.42 0.14 1.05 Remain

[0062] The ultra-high temperature soft core forging process is performed on the 9-ton H13 steel ingot. The specific steps are as follows:

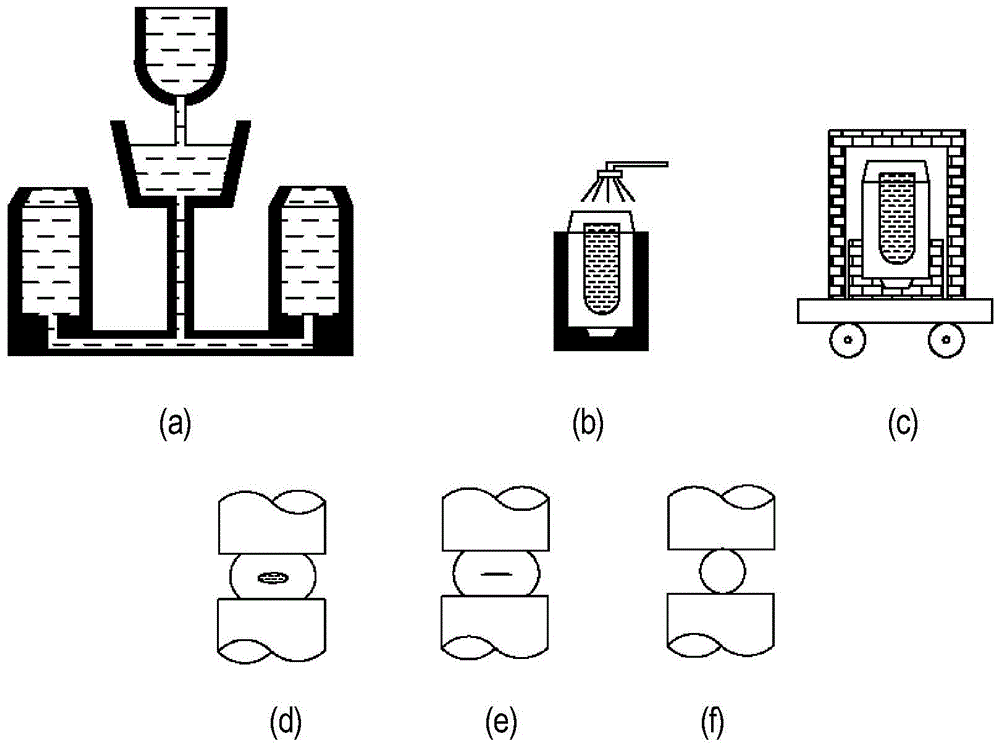

[0063] The first step is ultra-high temperature demoulding. 3.5 hours after pouring the steel ingot, blow off the protective slag from the riser to release the steel ingot with a liquid core at ultra-high temperature.

[0064] The second step is to close the top of the riser. The spray device is used to continuously act on the riser of the steel ingot for 10 minutes, so that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com