Aluminum alloy injection mold

An injection mold, aluminum alloy technology, applied in the field of molds, can solve the problems of easy overburning, difficult to control mold temperature, aluminum alloy molding and poor fluidity, etc., to avoid high or low temperature, solve pores, improve The effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

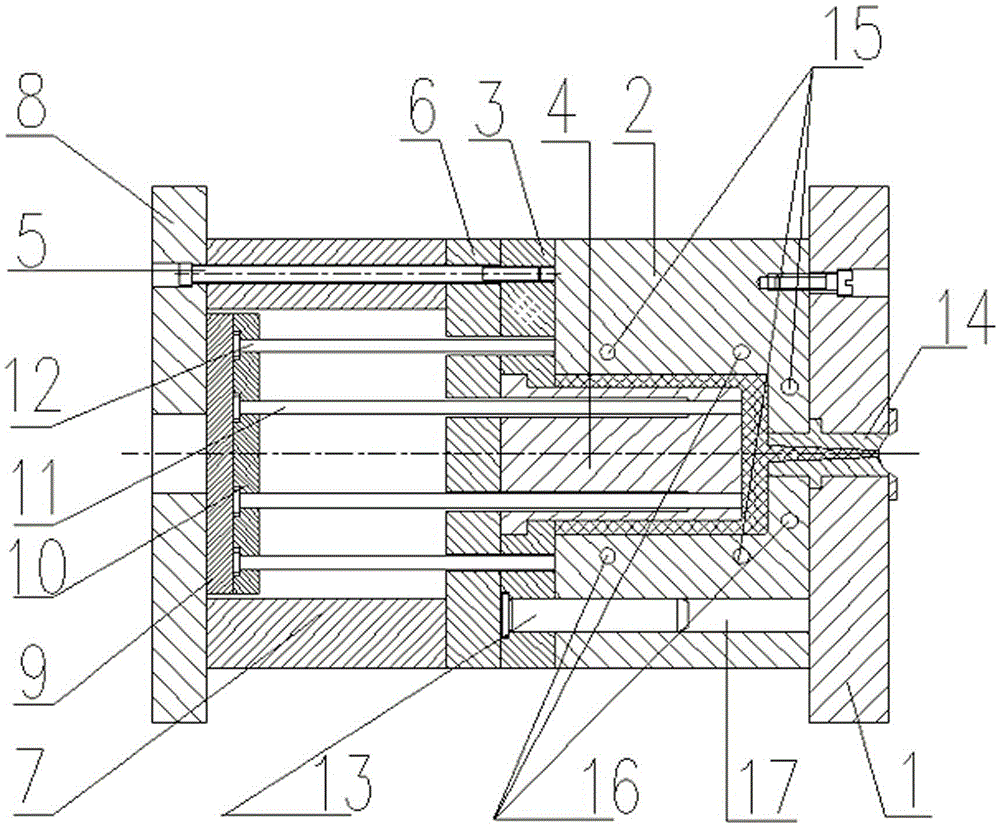

[0012] like figure 1 As shown, the aluminum alloy injection mold proposed by the present invention includes: a fixed mold and a movable mold, the fixed mold is composed of a fixed mold base plate 1 and a concave mold 2 fixed on it; the movable mold includes a movable template 3 and the punch 4 fixed on it, the punch and the punch form an injection cavity; the guide plate 6, the cushion block 7 and the movable die seat plate 8 connected to the movable die plate 3 through the screw 5 in turn; through the push plate 9 and the fixed plate 10 are arranged on the push rod 11 and the reset rod 12 on the movable die base plate, the push rod 11 passes through the guide plate 6 and the punch 4 in turn, and the reset rod 12 passes through the guide plate 6 and the movable template in turn. 3; between the guide plate 6 and the fixed die base plate 1, there ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap