A lamination molding apparatus

A technology of layered modeling and inert gas, which is applied in the directions of manufacturing auxiliary devices, processing and manufacturing, and manufacturing tools, etc., can solve the problems of difficulty in maintaining the concentration of inert gas and displacement of body moldings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described below using the drawings. Various characteristic matters shown in the embodiments shown below may be combined with each other.

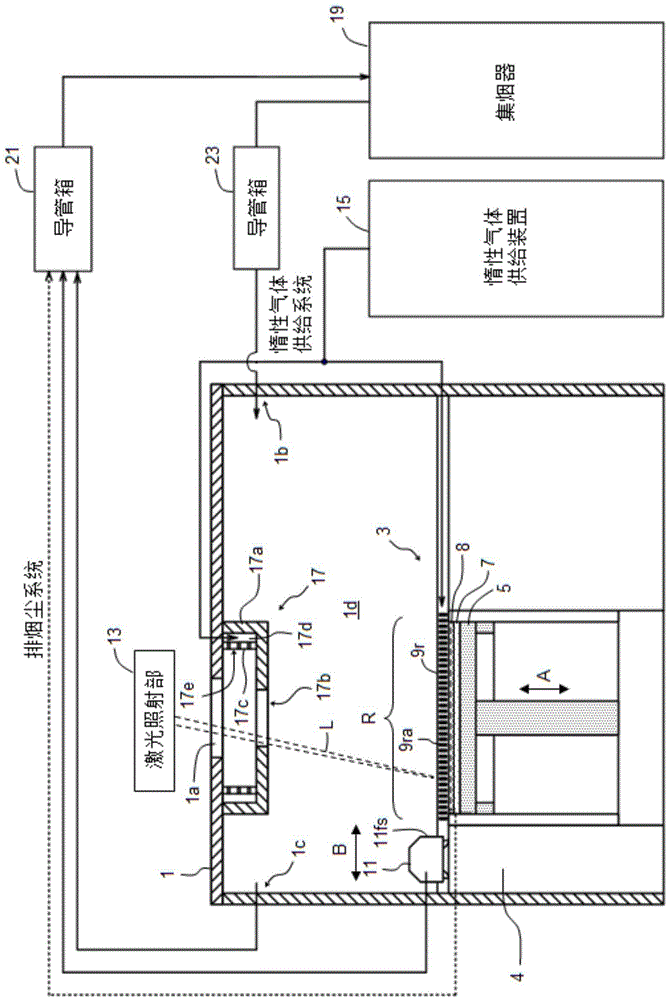

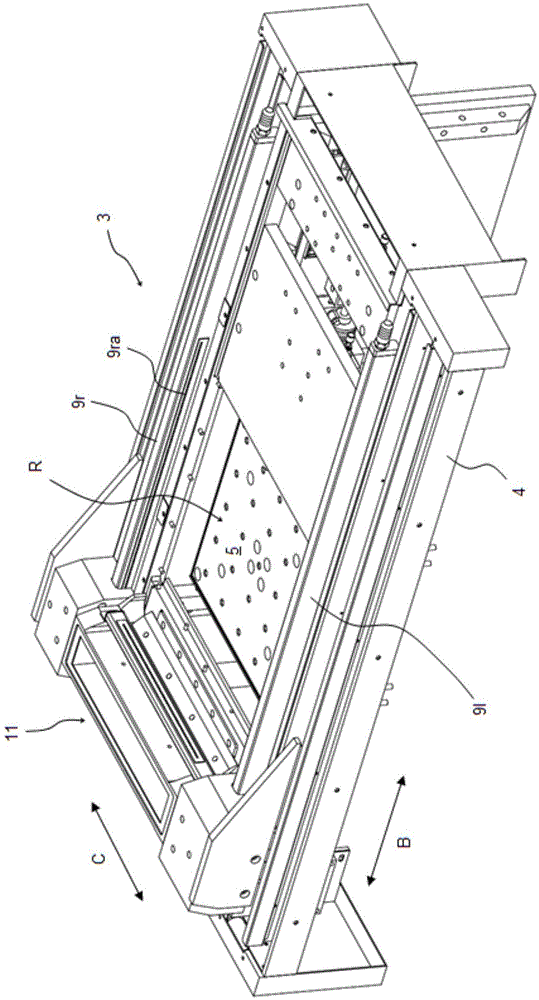

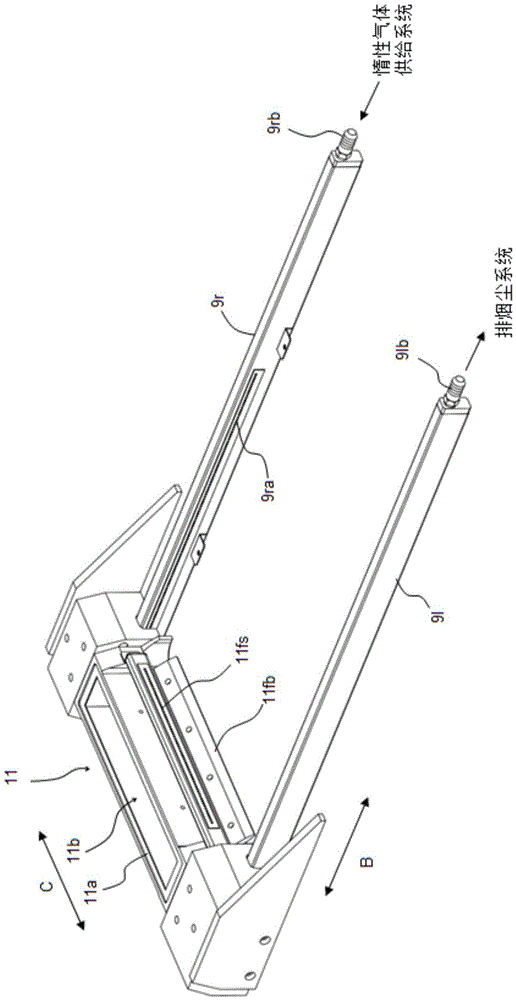

[0025] Such as Figure 1 ~ Figure 2 As shown, a powder layer forming device 3 is provided in a cavity 1 in a layered molding device according to an embodiment of the present invention. The powder layer forming device 3 is provided with: a base 4 having a modeling area R; a coating head 11 configured to be arranged on the base 4 and movable in a horizontal 1-axis direction (direction of arrow B); The components 9r, 9l are arranged on both sides of the styling area R along the moving direction of the coating head 11. In the modeling area R, there is a set that can be used in the up and down direction ( figure 1 Arrow A direction) moving modeling table 5. When a stacked molding device is used, a molding plate 7 is arranged on the molding table 5, and a material powder layer 8 is formed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com