Shell, manufacturing method of shell, and electronic device with shell

A manufacturing method and shell technology, applied to circuits, telephone communications, electrical components, etc., can solve the problems of large width, reduced service life of electronic devices, large internal space, etc., and achieve the effect of small size and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

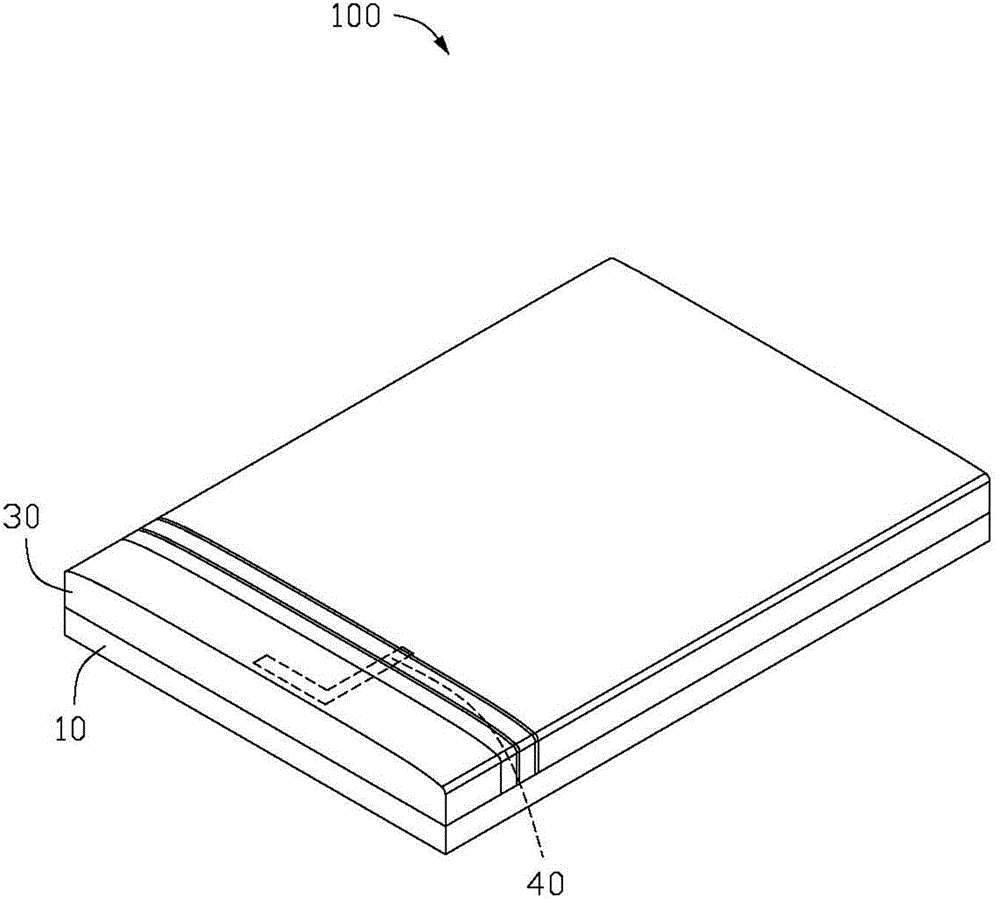

[0032] see figure 1 , An electronic device 100 according to a preferred embodiment of the present invention includes a main body 10 , a housing 30 disposed on the main body 10 and an antenna 40 accommodated in the main body 10 . The electronic device 100 can be a mobile phone, a PDA (Personal Digital Assistant), a tablet computer, and the like.

[0033] The body 10 may include a circuit board (not shown) and a battery (not shown) electrically connected to the circuit board. The battery is used to provide electric power for the electronic device 100 .

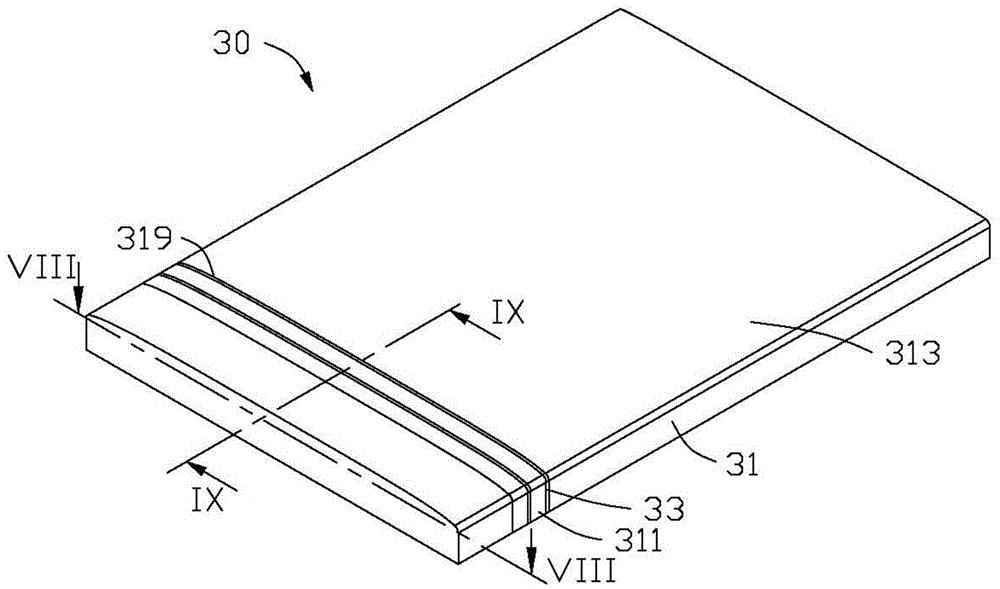

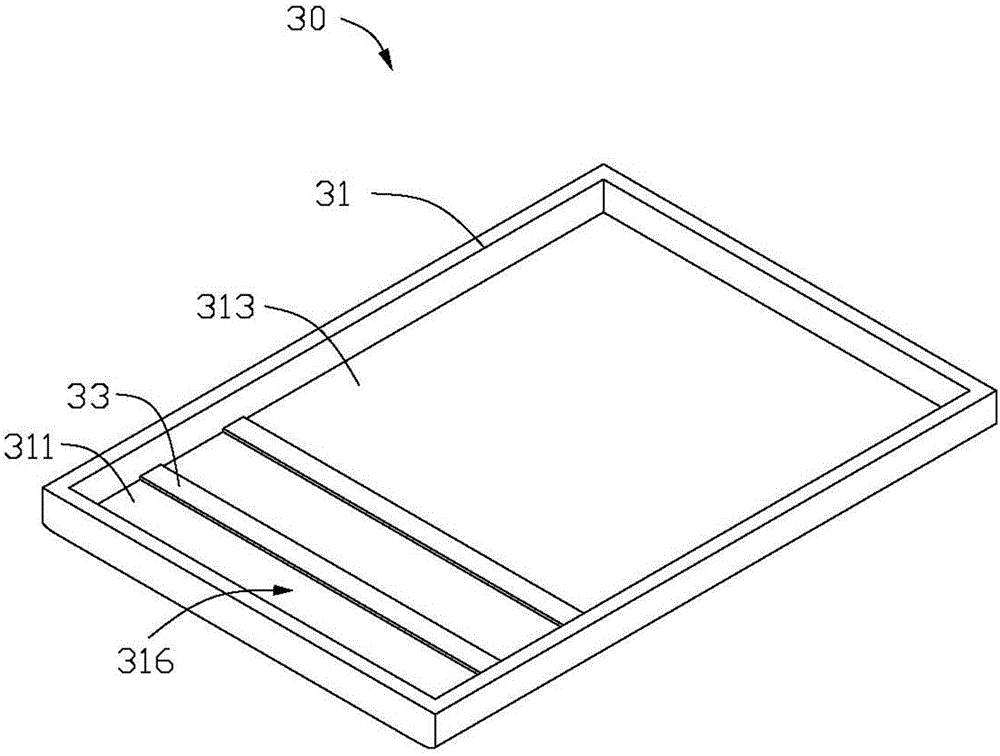

[0034] see Figure 2~3 , the casing 30 may be the back cover of the electronic device 100 . The casing 30 includes a metal base 31 and a non-conductive component 33 accommodated in the metal base 31 .

[0035] The material of the metal base 31 can be aluminum, aluminum alloy, magnesium, magnesium alloy, titanium, titanium alloy, copper, copper alloy and the like. The metal base 31 includes at least one metal sheet 311 and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com