Combined vacuum tire

A combined and vacuum technology, applied in the direction of segmented casing, etc., can solve the problems of the carcass not reaching the service life of the product, high manufacturing technology standards, and easy heating of the tread layer, so as to reduce the tire retreading process, save resources, Good for maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

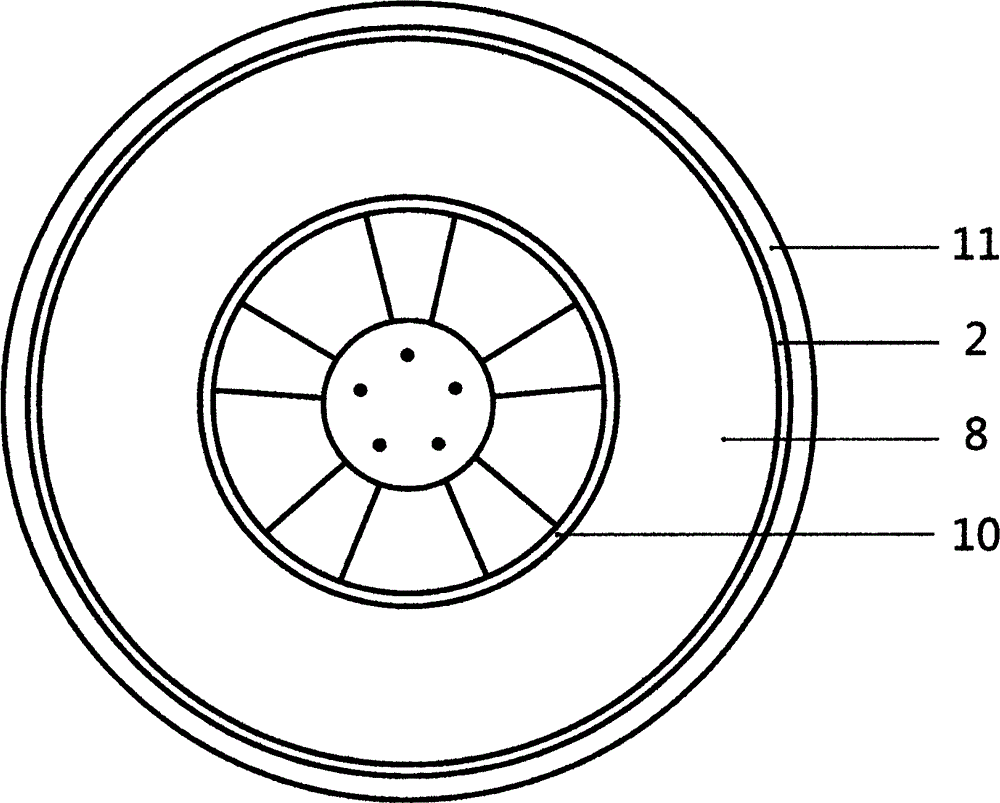

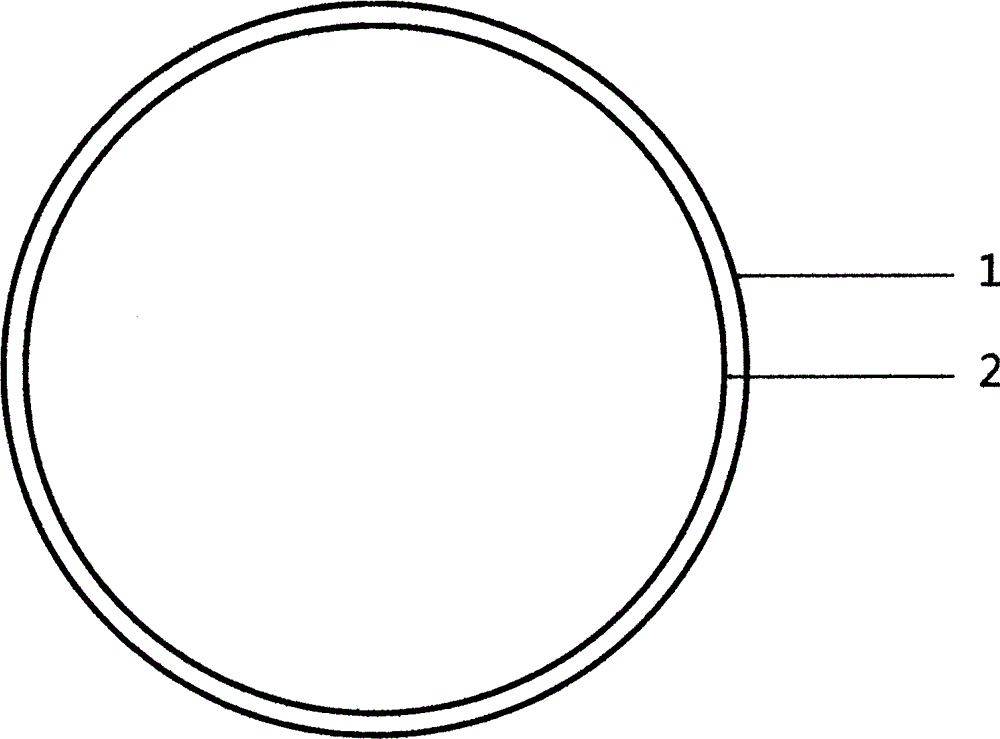

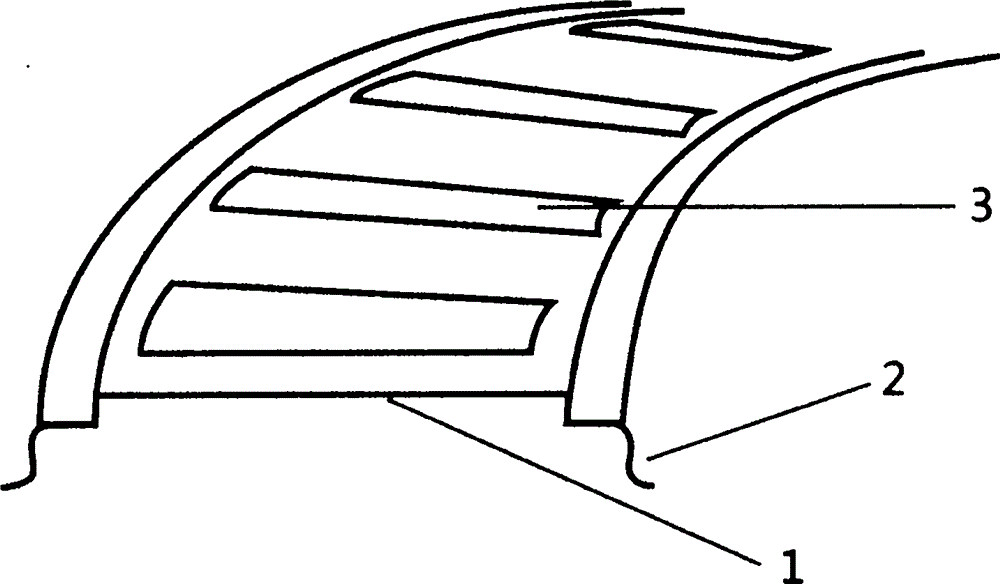

[0018] by figure 1 , image 3 , Figure 5 , technical requirements, were made into the outer hub and tire crown, and two independent sidewalls. Put the original wheel hub and the outer wheel hub flat on the tire loading machine, respectively install the two sidewalls into the inner and outer hubs, and fill in air to seal the bead until the standard air pressure is reached, such as Figure 6 . Install the outer wheel hub with the worn crown on the grinding machine, after grinding the tread, spread the pre-vulcanized tire crown rubber, and then vulcanize. Combined vacuum tires are suitable for all types of trucks, engineering vehicles and large passenger cars.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com