Synthetic method of high-silicon zeolite

A synthesis method and high-silica zeolite technology are applied in the directions of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc. to achieve the effects of avoiding heterocrystalline phases, improving product purity, and shortening synthesis reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

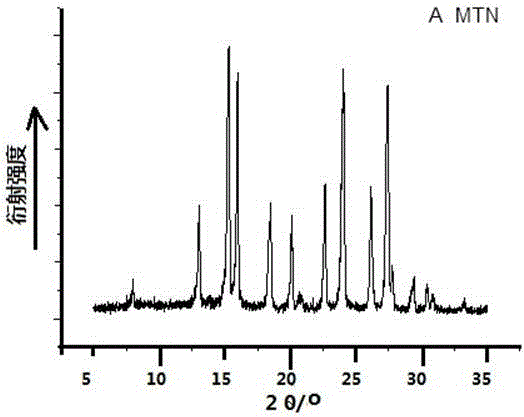

Embodiment 1

[0028] Use quartz glass powder as silicon source, ethylamine (EA) as template, add FER (ferrierite) molecular sieve crystal (SAR=20) as seed crystal, according to EA: 0.1Na 2 O: SiO 2 : 12H 2 Mix O: 0.05FER evenly, put it into a stainless steel pressure-resistant reactor with a capacity of 100ml, place the reactor in an oven at 180°C, and perform a hydrothermal reaction under self-generated pressure for 24 hours. The reaction product is filtered, washed, and dried. , to obtain MTN zeolite crystals.

Embodiment 2

[0030] Use quartz glass powder as silicon source, ethylamine as template, add MOR (mordenite) molecular sieve crystal (SAR=13) as seed crystal, according to EA: 0.1Na 2 O: SiO 2 : 12H 2 Mix O: 0.05MOR evenly, put it into a stainless steel pressure-resistant reactor with a capacity of 100ml, place the reactor in an oven at 180°C, and perform a hydrothermal reaction under self-generated pressure for 24 hours. The reaction product is filtered, washed, and dried. , to obtain MTN zeolite crystals.

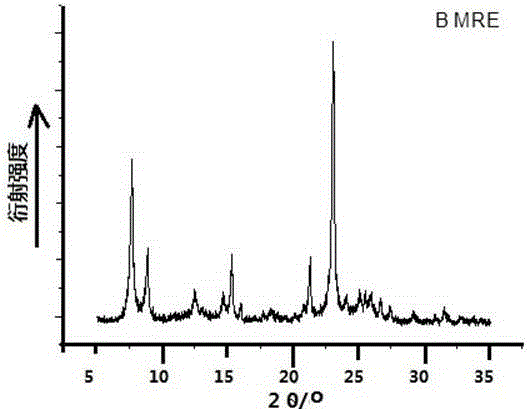

Embodiment 3

[0032] Using quartz glass powder as the silicon source, ethylamine as the template, and FAU (high silicon Y zeolite) molecular sieve crystal (SAR=90) as the seed crystal, according to EA: 0.1Na 2 O: SiO 2 : 12H 2 Mix O: 0.05FAU evenly, put it into a stainless steel pressure-resistant reactor with a capacity of 100ml, place the reactor in an oven at 180°C, and perform a hydrothermal reaction under self-generated pressure for 24 hours. The reaction product is filtered, washed, and dried. , to obtain MRE zeolite crystals.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap