Calcination method for raising daily output of rare earth carbonate

A technology of rare earth carbonate and daily output, applied in the field of material science, can solve the problems of high labor consumption, low production efficiency, high energy consumption, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

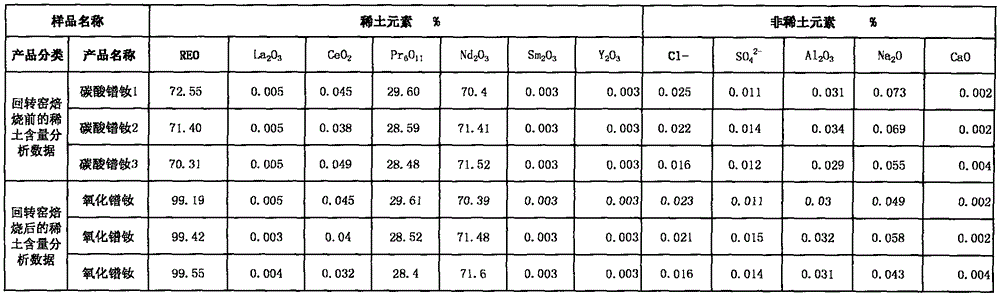

Embodiment 1

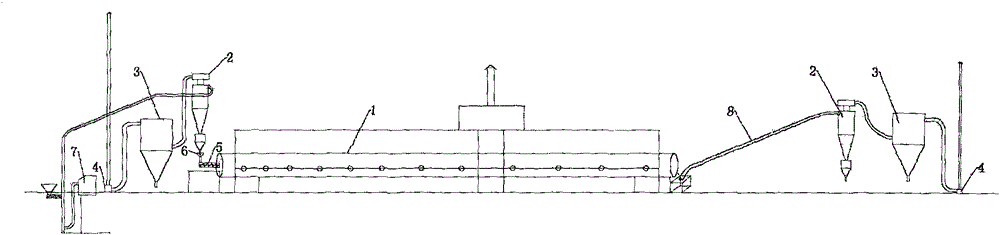

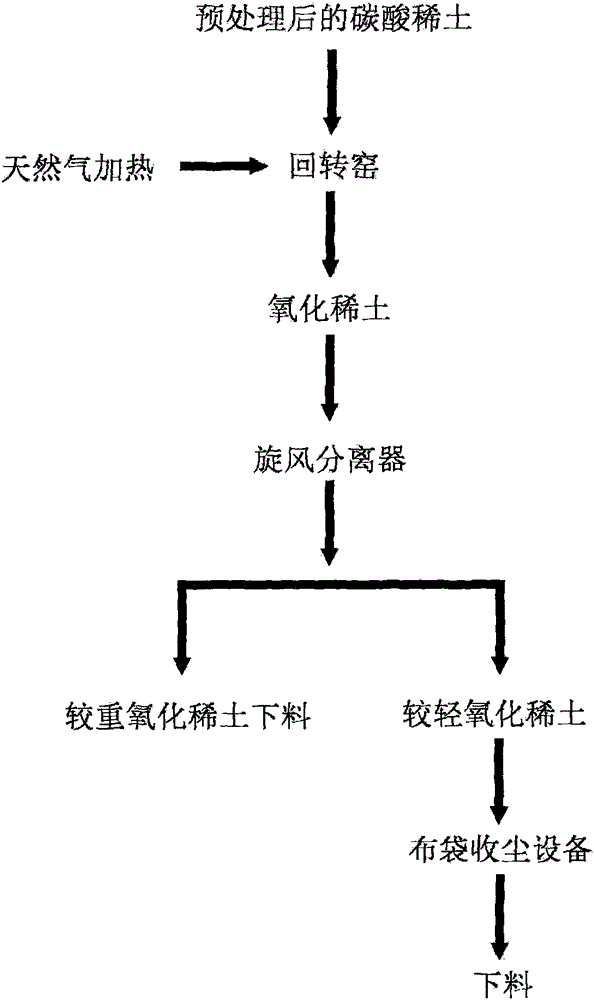

[0026] A kind of roasting method that improves daily output of rare earth carbonate, concrete steps are as follows:

[0027] Step 1: NdPr carbonate enters the conveying pipe and uses the dry hot air provided by the hot blast stove to dry the material, and with the power provided by the induced draft fan, the NdPr carbonate with a total mass greater than 70% is separated and unloaded by a cyclone separator ;

[0028] Step 2. The materials taken away by the wind during the separation process are collected through the bag for dust collection, and then discharged through the bag dust collection discharge port;

[0029] Step 3, put the blanking material obtained in step 1 and step 2 into the kiln head receiving hopper, and then feed the material into the rotary kiln at a stable and uniform speed by controlling the frequency of the auger;

[0030] Step 4. The material is turned over in the kiln through the large and small lifting plates on the wall of the cylinder, and the retainin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com