Bottle making machine and its turntable driving device

A driving device and bottle making machine technology, applied in the direction of manufacturing tools, glass manufacturing equipment, glass reshaping, etc., can solve the problems of complex lifting mechanism structure, affecting the accuracy of glass bottles, complex transmission structure, etc., to achieve relatively flexible rotation, The effect of simple structure and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to enable those skilled in the art to better understand the various technical solutions involved in the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments in this application and the specific technical features described in the embodiments can be combined in any suitable way; The possible combinations are not further described, as long as they do not violate the idea of the present invention, they should also be regarded as the content disclosed in the present invention.

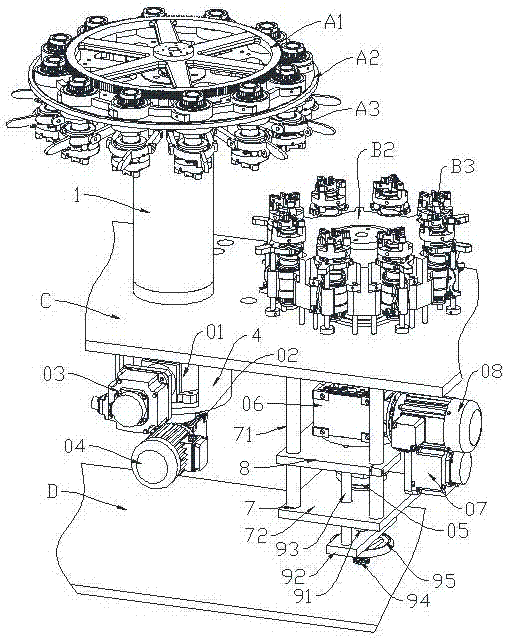

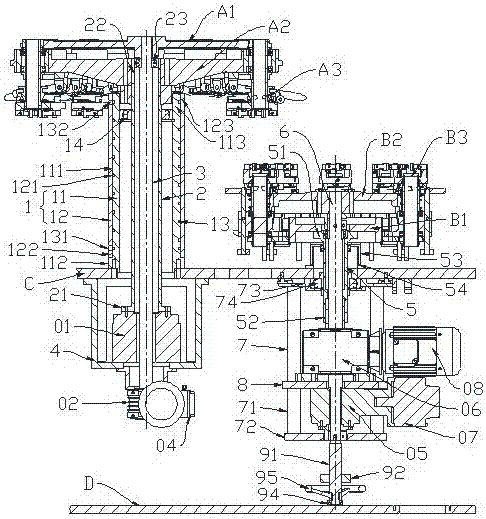

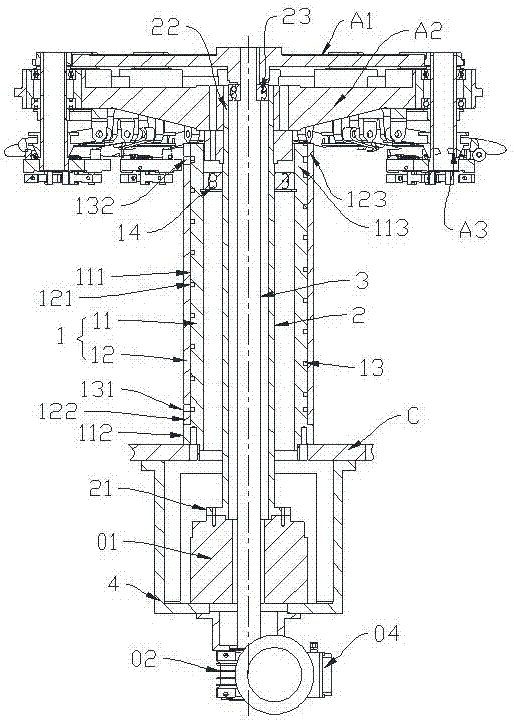

[0051] like figure 1 , figure 2 , image 3 and Figure 4 as shown, figure 1 It is a schematic diagram of the three-dimensional structure principle of the turntable drive device provided by a specific embodiment of the present invention; figure 2 figure 1 Schematic diagram of the longitudinal section of the provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com