Once-fired glass-ceramic composite brick and its production method

A technology of glass-ceramic ceramics and a production method, which is applied in the field of ceramic tile production, can solve the requirements of the technical level of transparent microcrystalline dry particles and the management of production process, the increase of related glaze pinhole defects, and the difficulty in reducing the reduction of glass-ceramic layers. Thin and other problems, to reduce the possibility of later cracking and cold working cracking, improve thermal stability and acid and alkali resistance, and solve the overall brick shape problem.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

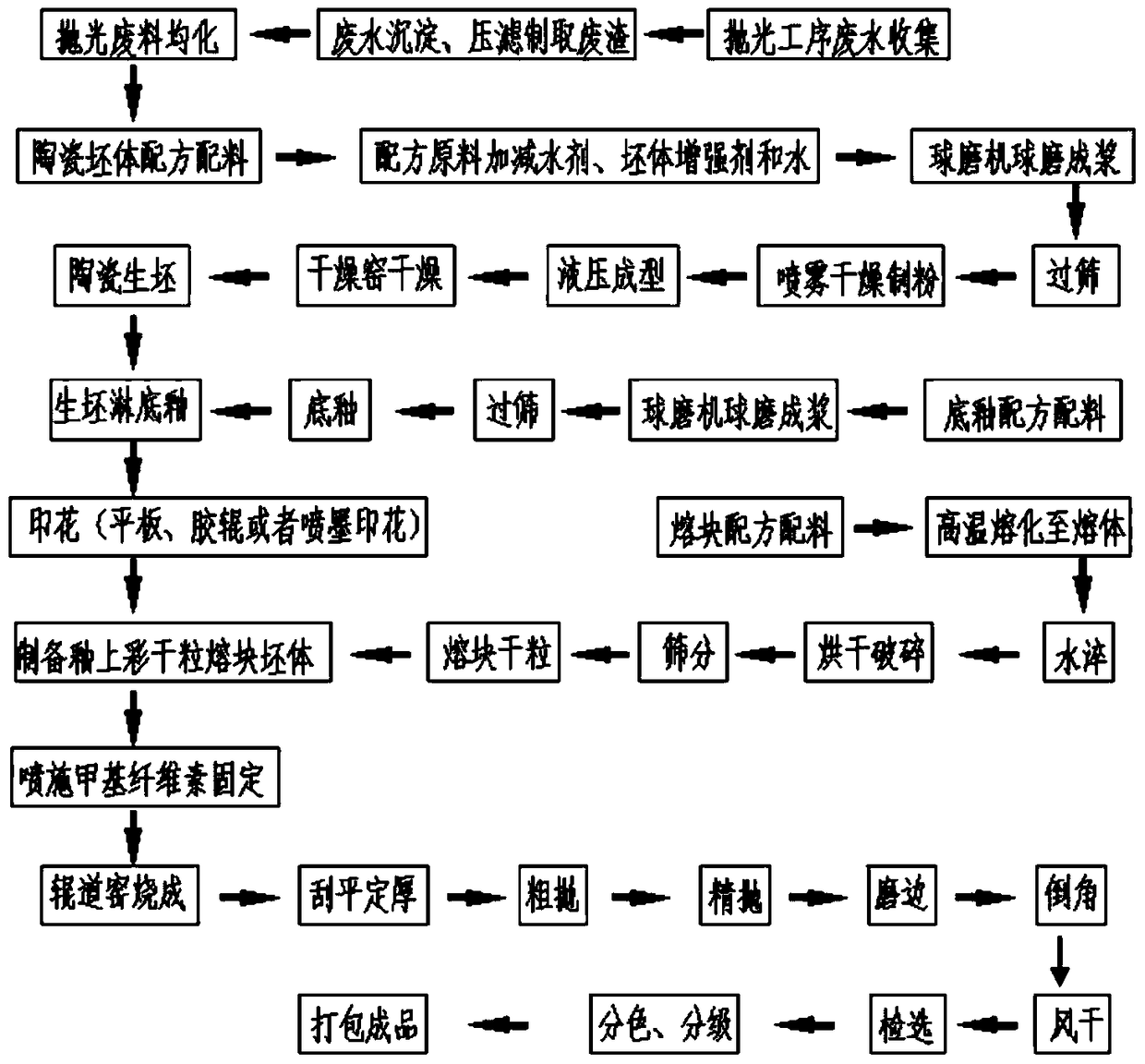

[0043] The production method of the once-fired glass-ceramic composite brick has the following steps:

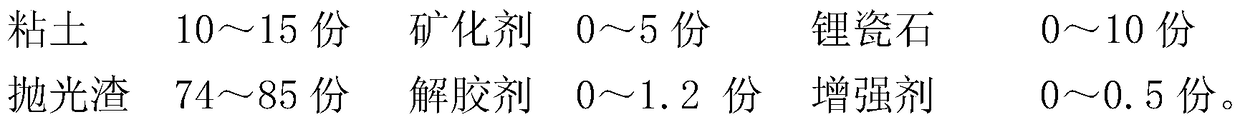

[0044] (1) preparing ceramic tile blanks, the ceramic tile blank formula is composed of the following components by weight:

[0045]

[0046] The ingredients are wet-milled and spray-dried, and then dry-pressed to obtain a ceramic green body, which is crushed to less than 5mm;

[0047] (2) Weighing according to the formula, wet ball milling until the remaining 1.5-2.00% is sieved by a million-hole sieve, spraying and granulating into a powder with a water content of about 7%, and then pressing it into a 903×903mm brick with a thickness of 11.0±0.3 with a 4,800-ton automatic hydraulic press mm of adobe, then dry it to a green body with a moisture content of less than 0.5%;

[0048] (3) Preparation of glass-ceramic composite tile glaze body, the composite tile glaze body is composed of the following components in parts by weight: 81 parts of HG-1 frit, 12 parts of kaolin, ...

Embodiment 2

[0058] The production method of the once-fired glass-ceramic composite brick has the following steps:

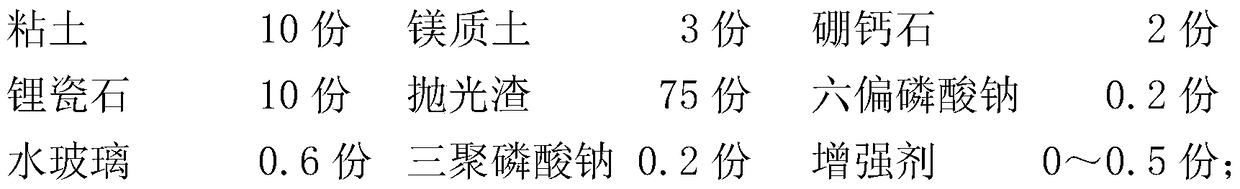

[0059] (1) preparing ceramic tile blanks, the ceramic tile blank formula is composed of the following components by weight:

[0060]

[0061] After batching, wet ball milling, spray drying, and dry pressing to obtain ceramic green bodies, which are crushed to less than 5mm;

[0062] (2) Weighing according to the formula, wet ball milling until the remaining 1.5-2.00% is sieved by a million-hole sieve, spraying and granulating into a powder with a water content of about 7%, and then pressing it into a 903×903mm brick with a thickness of 11.0±0.3 with a 4,800-ton automatic hydraulic press mm of adobe, then dry it to a green body with a moisture content of less than 0.5%;

[0063] (3) Prepare the glass-ceramic composite tile glaze base, and the composite tile glaze base is made up of the following components by weight:

[0064] 90 parts of HG-1 frit, 8 parts of kaolin, 2 p...

Embodiment 3

[0074] The production method of the once-fired glass-ceramic composite brick has the following steps:

[0075] (1) preparing ceramic tile blanks, the ceramic tile blank formula consists of the following components in parts by weight:

[0076]

[0077] After the formula is prepared, the ceramic green body is made by wet ball milling, spray drying, and then dry pressing, which is crushed to less than 5mm;

[0078] (2) Weighing according to the formula, wet ball milling until the remaining 1.5-2.00% is sieved by a million-hole sieve, spraying and granulating into a powder with a water content of about 7%, and then pressing it into a 903×903mm brick with a thickness of 11.0±0.3 with a 4,800-ton automatic hydraulic press mm of adobe, then dry it to a green body with a moisture content of less than 0.5%;

[0079] (3) Prepare the glass-ceramic composite tile glaze blank,

[0080] Preparation of glass-ceramic composite tile glaze body: the composite tile glaze body consists of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com