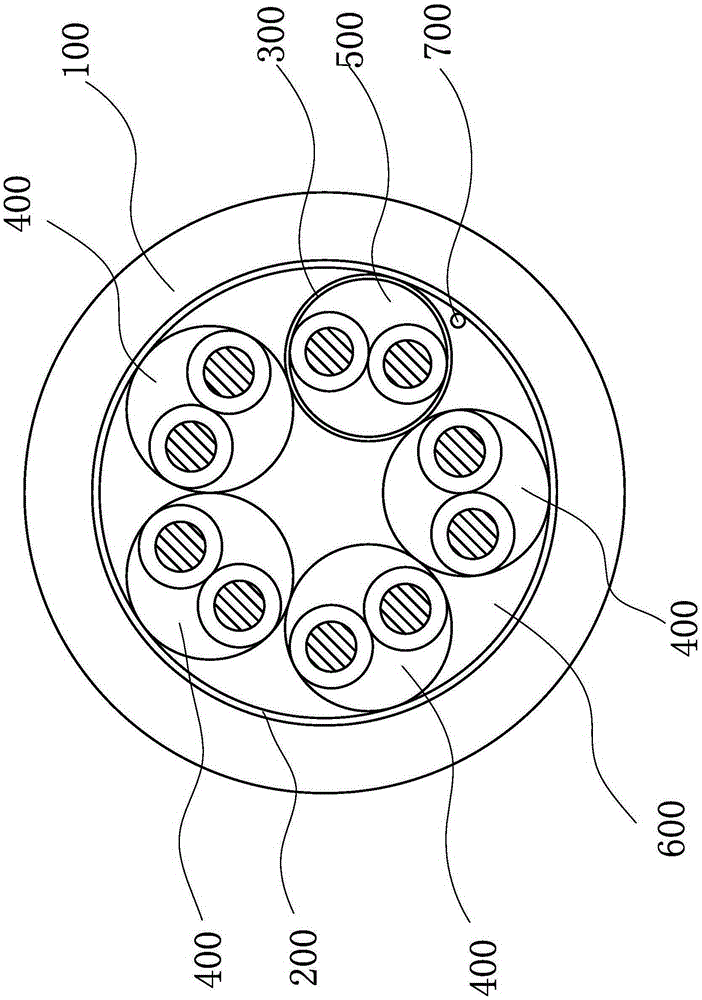

Elevator cable

A technology for elevator cables and sheaths, applied in the field of elevator cables, can solve problems such as increased material costs, inconvenient cable installation, interference, etc., and achieve the effects of saving costs, improving anti-interference ability, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

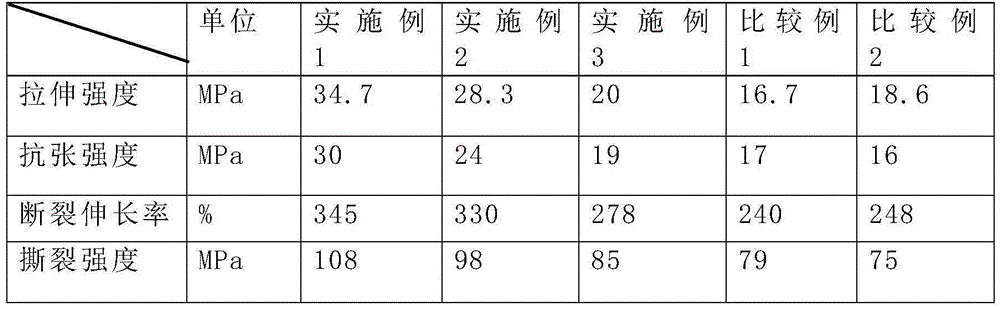

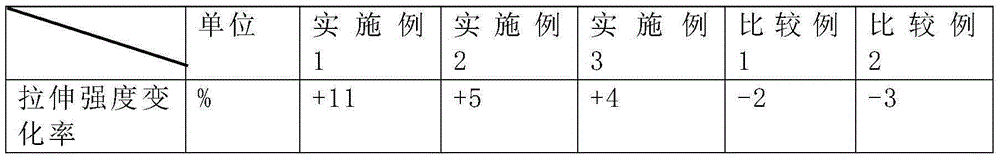

Embodiment 1

[0038] In an elevator cable, the raw materials of the sheath include 50 parts by weight of polyethylene, 30 parts of chlorinated polyvinyl chloride resin, 15 parts of chlorosulfonated polyethylene, 25 parts of modified polyphenoxy resin, and 16 parts of quartz powder. 2 parts, 2 parts of aluminum hydroxide, 3 parts of magnesium hydroxide, 0.9 part of tert-butyl perbenzoate, 3 parts of antioxidant, 0.4 part of antioxidant, 2 parts of crosslinking agent, 1.8 parts of white carbon black.

[0039] The preparation method of above-mentioned sheath comprises the following steps:

[0040] (1) Mix and stir, mix and stir the materials with the following weight ratio components evenly, 50 parts of polyethylene, 30 parts of chlorinated polyvinyl chloride resin, 15 parts of chlorosulfonated polyethylene, 25 parts of modified polyphenoxy resin , 16 parts of quartz powder, 2 parts of aluminum hydroxide, 3 parts of magnesium hydroxide, 0.9 part of tert-butyl perbenzoate;

[0041] (2) Melt, h...

Embodiment 2

[0046] The raw materials of the above-mentioned sheath include: 55 parts of polyethylene, 25 parts of chlorinated polyvinyl chloride resin, 17 parts of chlorosulfonated polyethylene, 25 parts of modified polyphenoxy resin, 17 parts of quartz powder, aluminum hydroxide 3 parts, 2.3 parts of magnesium hydroxide, 0.9 part of tert-butyl perbenzoate, 3.5 parts of antioxidant, 0.4 part of antioxidant, 2 parts of crosslinking agent, and 1 part of white carbon black.

[0047] The preparation method of above-mentioned sheath comprises the following steps:

[0048] (1) Mix and stir, mix and stir the following materials by weight ratio evenly, 55 parts of polyethylene, 25 parts of chlorinated polyvinyl chloride resin, 17 parts of chlorosulfonated polyethylene, 25 parts of modified polyphenoxy resin , 17 parts of quartz powder, 3 parts of aluminum hydroxide, 2.3 parts of magnesium hydroxide, 0.9 part of tert-butyl perbenzoate;

[0049] (2) Melt, heat the mixed material to 144-155°C, then...

Embodiment 3

[0054] The raw materials of the above-mentioned sheath include: 53 parts of polyethylene, 16 parts of chlorinated polyvinyl chloride resin, 16 parts of chlorosulfonated polyethylene, 22 parts of modified polyphenoxy resin, 17 parts of quartz powder, aluminum hydroxide 2 parts, 2.5 parts of magnesium hydroxide, 0.8 parts of tert-butyl perbenzoate, 4 parts of antioxidant, 0.4 parts of antioxidant, 2 parts of crosslinking agent, and 2 parts of white carbon black.

[0055] The preparation method of above-mentioned sheath comprises the following steps:

[0056] (1) Mix and stir, mix and stir the following materials by weight ratio evenly, 53 parts of polyethylene, 16 parts of chlorinated polyvinyl chloride resin, 16 parts of chlorosulfonated polyethylene, 22 parts of modified polyphenoxy resin , 17 parts of quartz powder, 2 parts of aluminum hydroxide, 2.5 parts of magnesium hydroxide, 0.8 part of tert-butyl perbenzoate;

[0057] (2) Melt, heat the mixed material to 144-155°C, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com