Solid Particle Recovering and Removing Apparatus, Liquid Managing Apparatus and Etching Solution Managing Apparatus

A solid particle and liquid technology, which is applied in the field of solid particle recovery and removal devices, can solve the problems of time-consuming processing, large sedimentation tanks, and a large amount of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

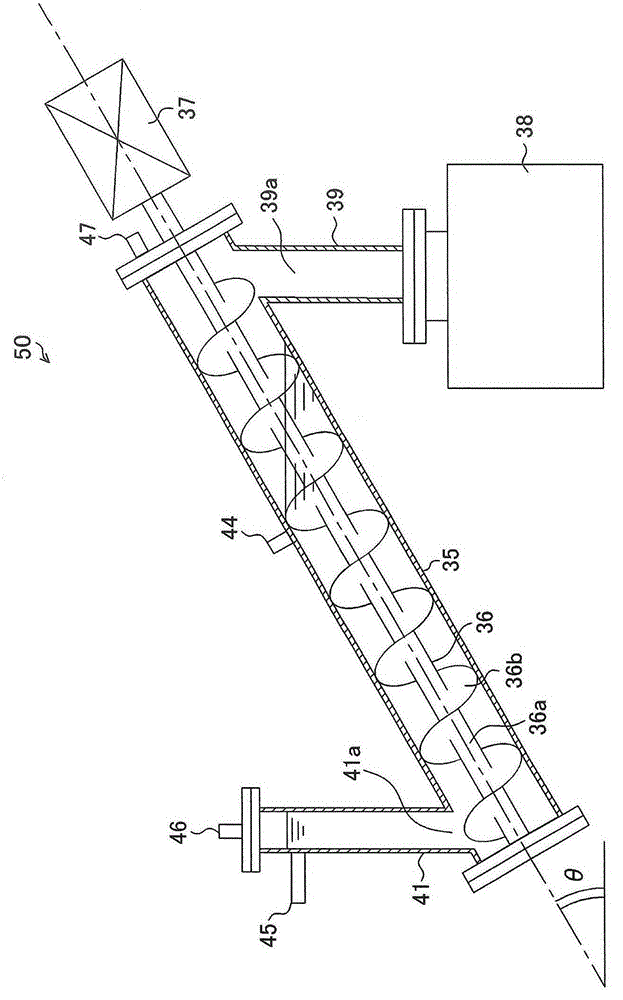

[0040] figure 1 It is a schematic diagram of the solid particle recovery and removal apparatus 50 of the first embodiment. like figure 1 As shown, the solid particle recovery and removal device 50 mainly includes a housing 35 inclined at a predetermined angle θ with respect to the horizontal, a conveying screw 36, a motor 37 for rotating the conveying screw 36, a solid particle recovery container 38, and a shell for A connecting pipe (a solid particle discharge pipe) 39 that discharges the solid particles in the body 35 to the solid particle recovery container 38 . The housing 35 is formed in a cylindrical shape, and a conveying screw 36 is provided in the housing.

[0041] The conveying screw 36 is provided along the longitudinal direction in the casing 35 , and a screw blade 36 b is attached in a helical shape around a central shaft 36 a rotated by a motor 37 . The conveying screw 36 is provided in the casing 35 so as to be close to the inner wall of the casing 35 . By r...

no. 2 approach

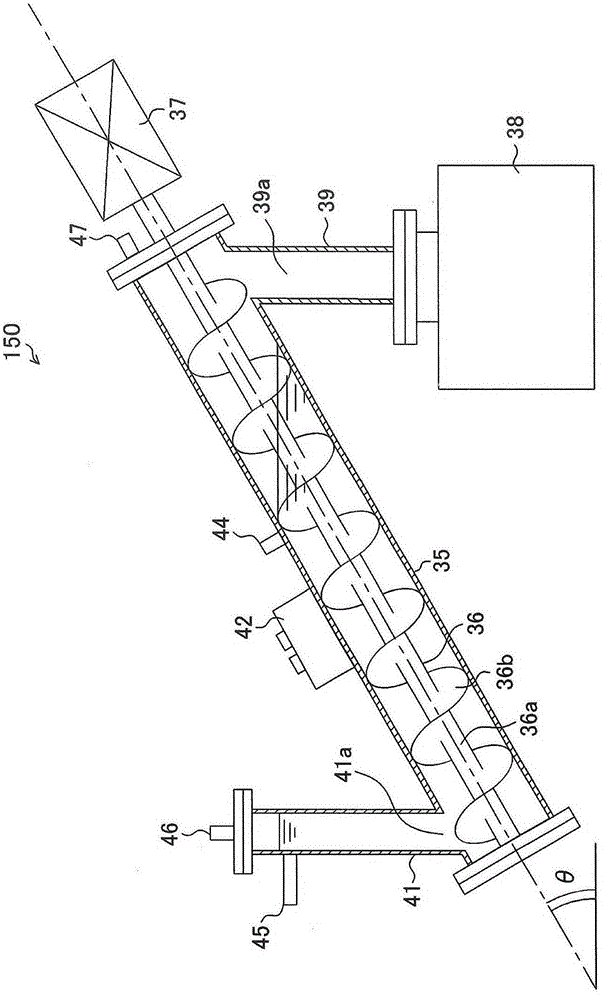

[0049] figure 2 It is a schematic diagram of the solid particle recovery and removal device 150 of the second embodiment. The solid particle recovery and removal apparatus 150 of the second embodiment is different from the first embodiment in that a heat exchange unit (cooling mechanism) 42 for cooling the liquid in the casing 35 is provided on the outer peripheral surface of the casing 35 .

[0050] The heat exchanging unit 42 includes, for example, a thermoelectric micromodule constituted by a Peltier element or the like, and a heat exchange sleeve for absorbing heat of the thermoelectric micromodule, which is cooled by cooling water for discharging heat. It is preferable that the outer side of the housing 35 is covered with a heat insulating material (not shown) in order to achieve heat insulation from an external heat source. It should be noted that the heat exchange unit 42 may be a refrigerant jacket that circulates the refrigerant to surround the outer surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com