Diesel engine integral cylinder cover with air valves arranged in parallel

A cylinder head, integral technology, applied in the direction of cylinder head, cylinder, mechanical equipment, etc., can solve the problems of poor air passage flow capacity, poor thermal fatigue resistance, etc., achieve high flow capacity, reduce thermal stress, shorten length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

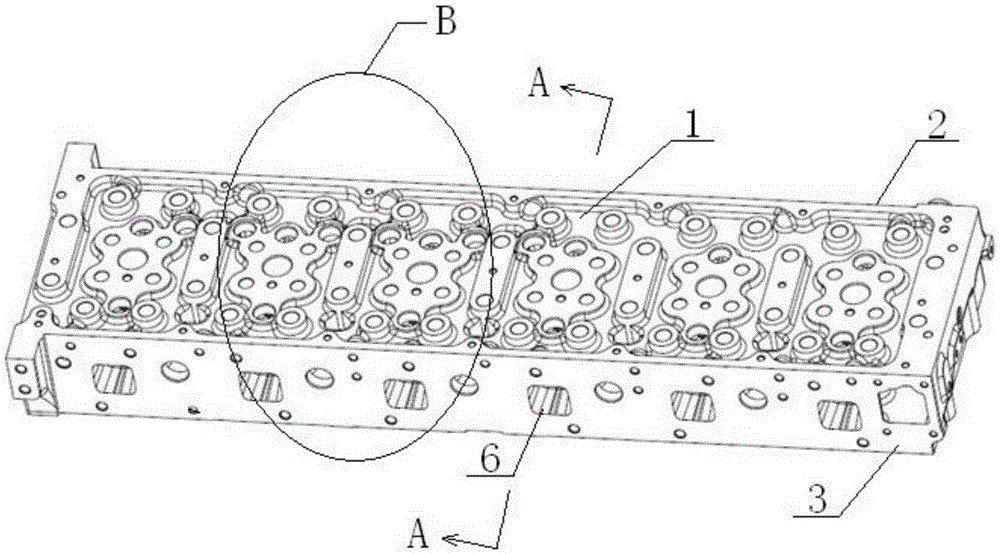

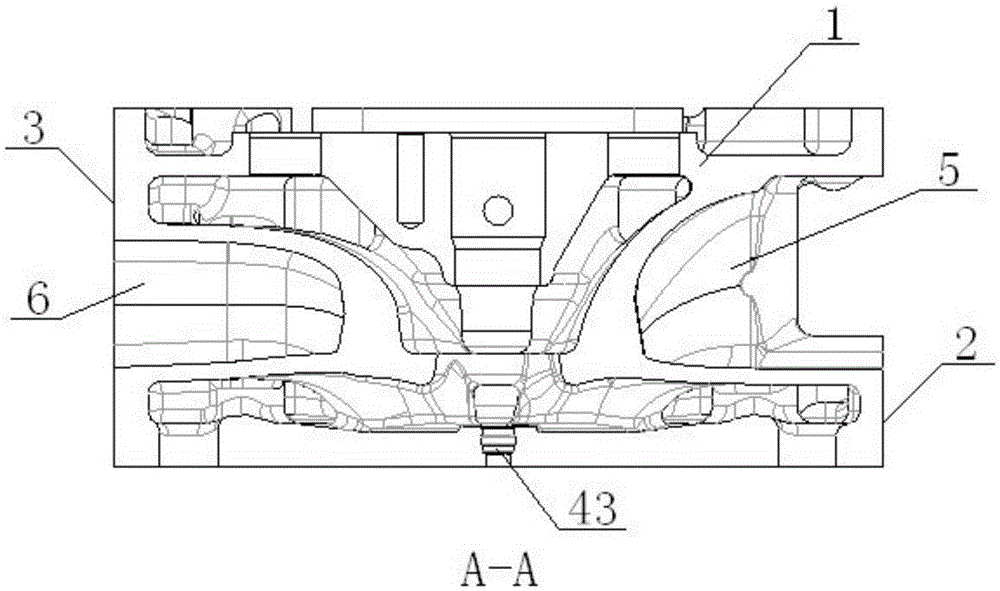

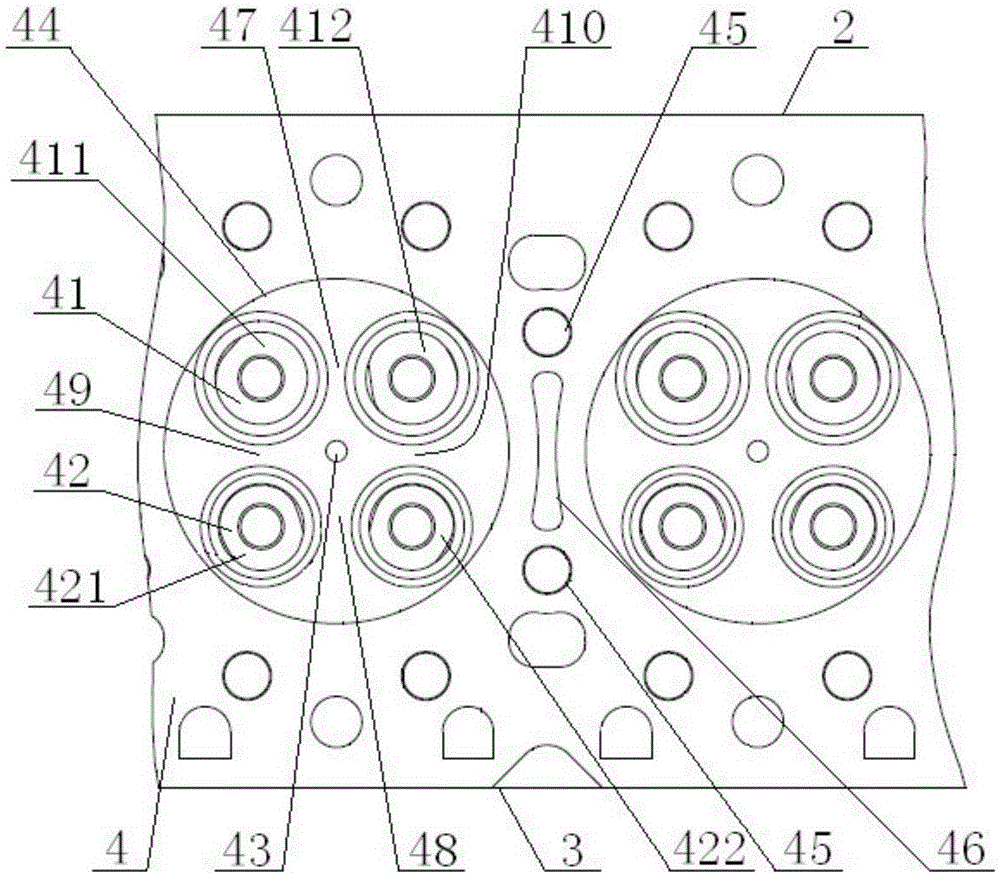

[0042] see Figure 1 to Figure 3 , an integral cylinder head of a diesel engine with parallel valve arrangements, comprising a cylinder head body 1 and an air intake passage 5 and an exhaust passage 6 provided inside, and one side of the cylinder head body 1 is an air intake port provided with an air intake port The side end surface 2, the other side of the cylinder head body 1 is the exhaust side end surface 3 provided with the exhaust port. Two intake valve holes 41, two exhaust valve holes 42 and one fuel injector hole 43 are corresponding to the cylinder, and the center of the bottom surface 4 of the cylinder head is provided with a fire surface sealing tape 44, which wraps the two inlet valve holes. Valve hole 41 , two exhaust valve holes 42 , fuel injector hole 43 , and fuel injector hole 43 is located at the central position of fire surface sealing band 44 .

[0043] The intake valve hole 41 is close to the end surface 2 on the intake side, and the center line of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com