Heat radiation device for LED automobile lens

A heat dissipation device and lens technology, applied in cooling/heating devices, signaling devices, lighting devices, etc. Efficiency, friction-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawings and embodiments thereof.

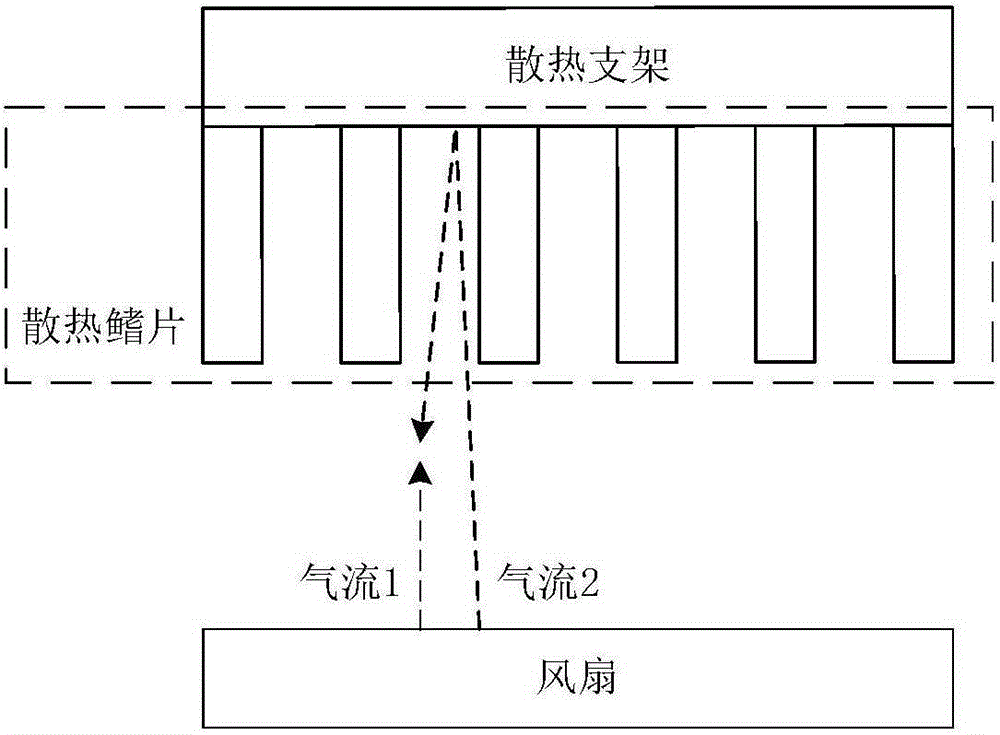

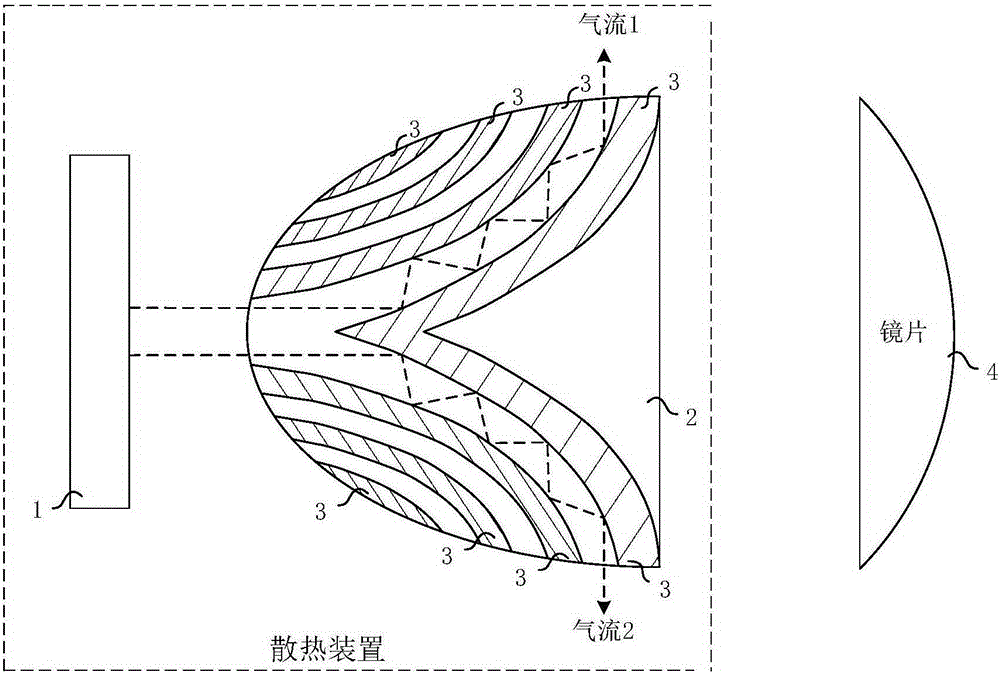

[0015] refer to figure 2 , the heat dissipation structure of LED automobile lens of the present invention, comprises cooling fan 1, support 2 and cooling fin 3; It is characterized in that: cooling fan 1 is positioned at the afterbody of support 2, and support 2 is provided with cooling fin 3. The airflow formed by the cooling fan 1 is blown horizontally to the bracket 2; the upper and lower surfaces of the bracket 2 are used to install LED chips and reflector cups; the cooling fins 3 include a plurality of fins arranged on the lower surface of the bracket 2; the fins of the cooling fins 3 The airflow direction formed by the fan 1 is curved to the left and right sides in a circular arc shape.

[0016] The working principle of the present invention is: the airflow formed by the heat dissipation fan 1 is blown to the heat dissipation fins 3. Since t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com