Fast electric water heater heating control method compatible with emc

An electric water heater and heating control technology, applied in fluid heaters, lighting and heating equipment, etc., can solve problems such as inability to meet EMC compatibility, flickering lights, and affecting the normal operation of other home appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

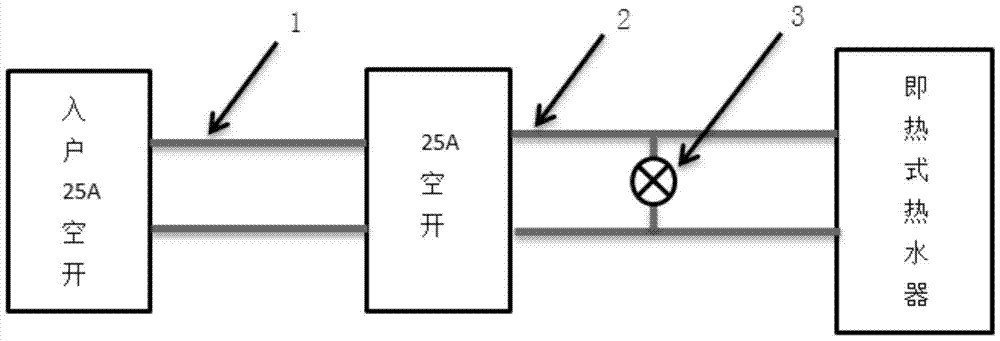

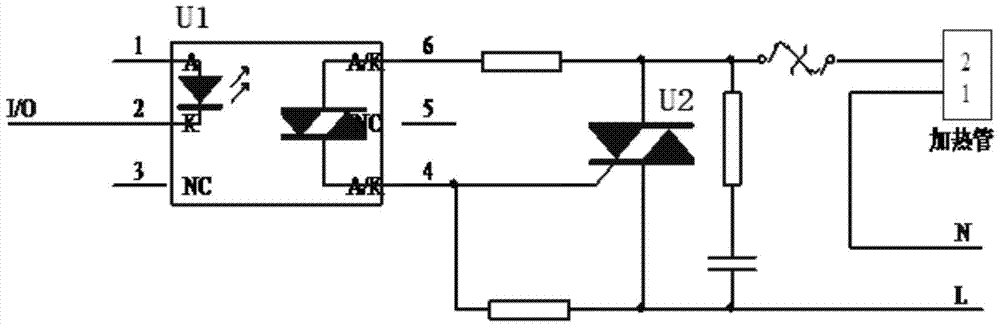

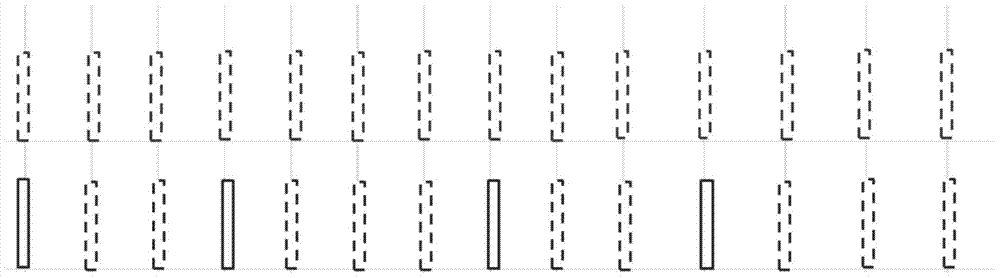

[0020] In view of the problem of EMC in the absence of safety devices such as large filters in the cut-wave control, and the problem of flicker in the conventional full-wave control, the present invention intends to provide a heating control method for a fast (instant heating) water heater, which can Overcome these two problems at the same time: in order to be compatible with EMC, the present invention adopts full-wave control, in order to test flicker problem, according to figure 1 The conditions shown are tested and obtained after field tests in different power consumption environments of different users (we have searched for harsh power consumption environments in many places at home and abroad). Figure 4-1 to Figure 4-26 Some waveforms are shown, these waveforms ensure that the lights do not flicker when the water h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com