Coaxial cable copper pipe connecting device

A technology of connecting device and coaxial cable, applied in the direction of two-part connecting device, conductive connection, connection, etc., can solve the problems of increasing the voltage standing wave ratio, increasing the difficulty of assembly, and easily breaking the contacts, reducing the contact resistance, The effect of solving early failure and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Take 7 / 8 coaxial cable as an example:

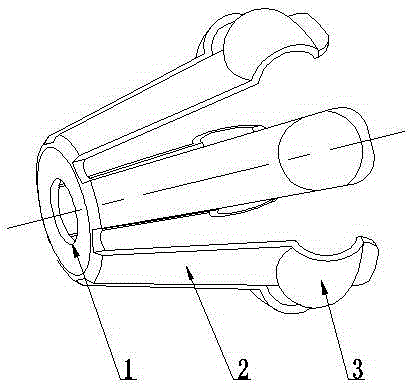

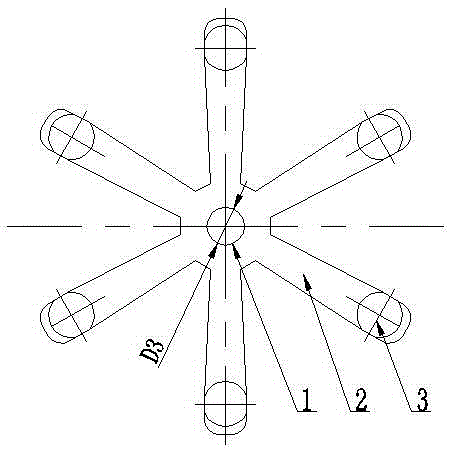

[0020] Such as figure 1 , a coaxial cable copper pipe connection device, including six identical shrapnel 2, each shrapnel 2 is formed by blanking and stamping on the same copper strip, and has the same material and mechanical properties.

[0021] In order to ensure the reliable connection between the device and the copper tube of the coaxial cable, the material of the shrapnel 2 is high-strength beryllium bronze QBe2, which is stamped and formed by a mold, and the forming size is determined by the specification of the coaxial cable.

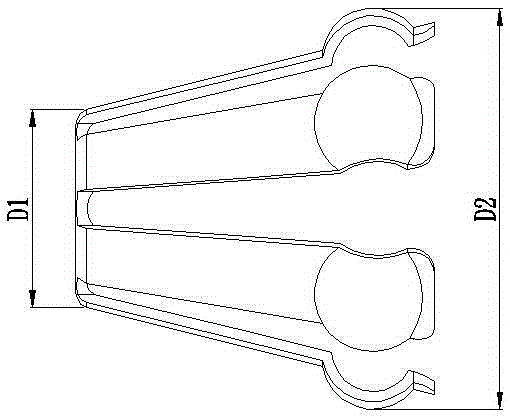

[0022] Such as image 3 , The outer diameter D2 of the spherical surface 3 at the top of the shrapnel 2 is greater than 13 mm, and the outer diameter D1 of the tail end of the shrapnel 2 is less than or equal to 6 mm.

[0023] The connection device after stamping is heat-treated in a vacuum furnace. The temperature in the furnace is 305-310°C, the holding time is 2H, and the vacuum cooling is belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com