Scenting equipment for processing of jasmine tea

A kind of scenting equipment and jasmine tea technology, which is applied in the field of jasmine tea production equipment, can solve the problems of low tea quality and achieve the effect of improving quality and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

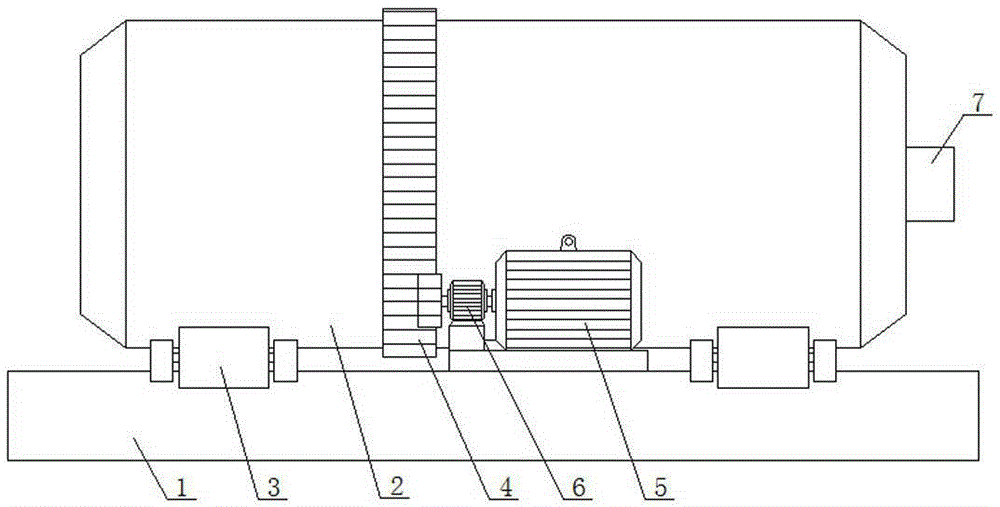

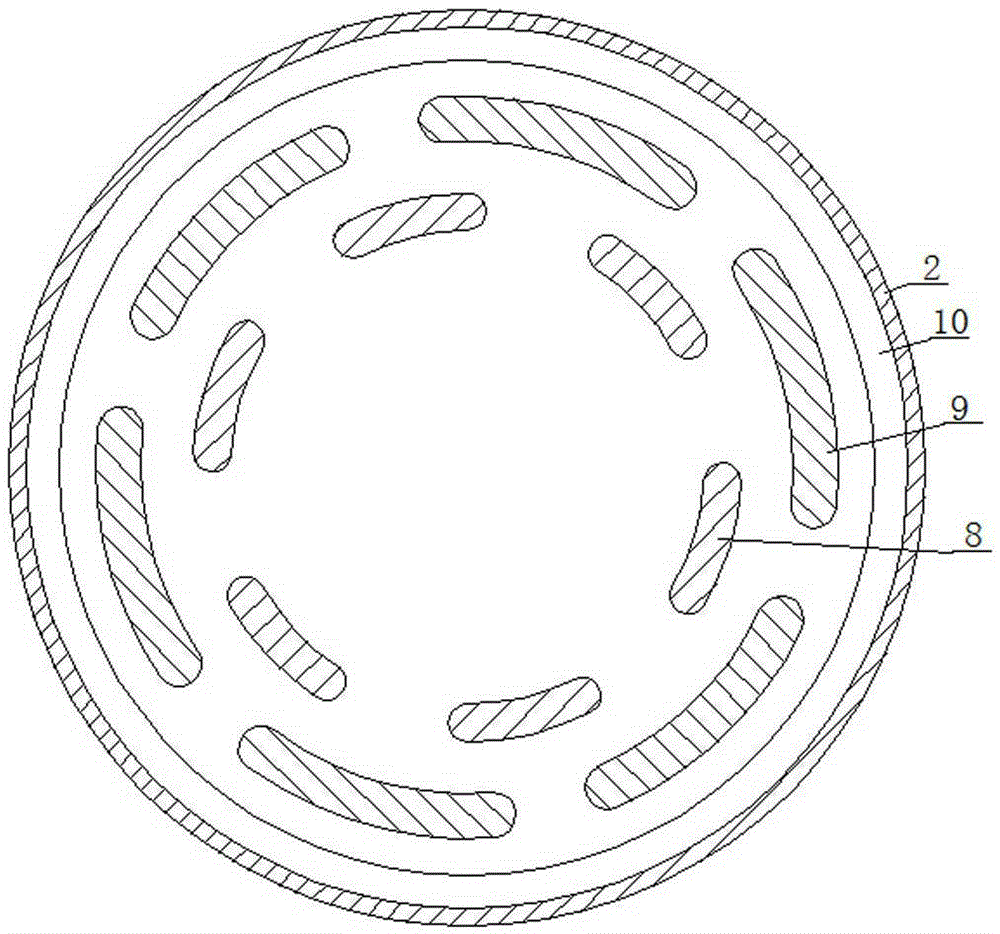

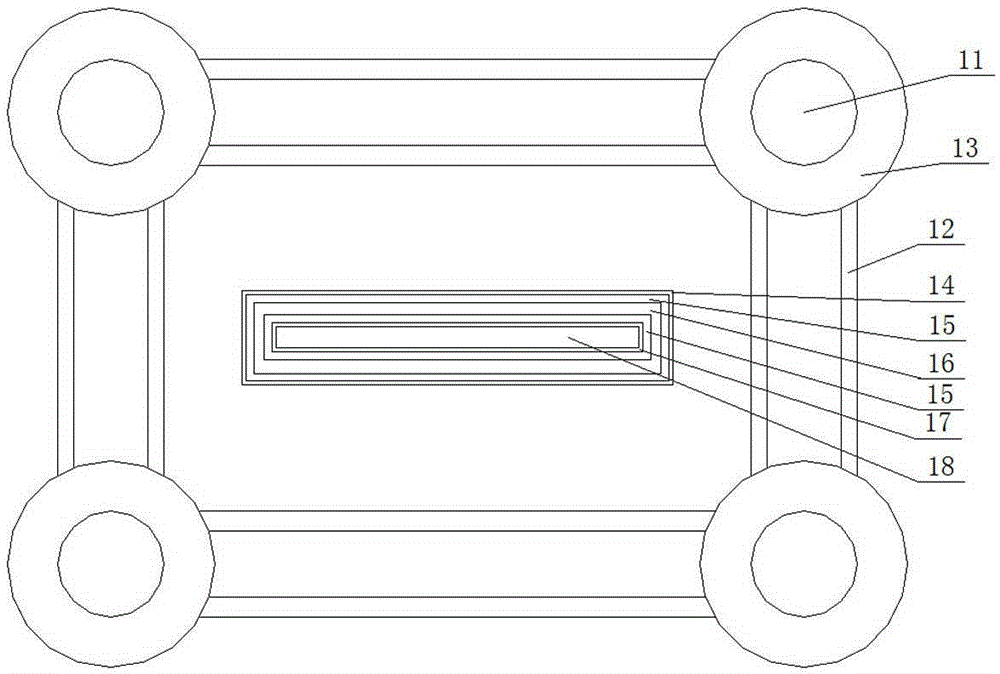

Embodiment 1

[0033]The scenting equipment for jasmine tea processing in this embodiment includes a base, a cylinder is provided on the base, a gear ring is provided on the outer surface of the cylinder, a supporting roller and a driving motor are provided on the base, The output shaft of the drive motor is connected with a reducer, and the output shaft of the reducer is connected with a driving gear meshed with a gear ring; the inside of the cylinder is provided with a shelf for placing jasmine along the axial direction of the cylinder. Receptacle, the space between the receptacle and the cylinder is used to place tea leaves; the receptacle includes a skeleton made of four stainless steels, the skeleton is equipped with a flower door that can be opened and closed, and the outer surface of the skeleton Covered with a screen; the center of the skeleton is provided with an electric heating device, the electric heating device includes an inner shell and an outer shell, the outer shell is set ou...

Embodiment 2

[0035] The scenting equipment for jasmine tea processing in this embodiment includes a base, a cylinder is provided on the base, a gear ring is provided on the outer surface of the cylinder, a supporting roller and a driving motor are provided on the base, The output shaft of the drive motor is connected with a reducer, and the output shaft of the reducer is connected with a driving gear meshed with a gear ring; the inside of the cylinder is provided with a shelf for placing jasmine along the axial direction of the cylinder. Receptacle, the space between the receptacle and the cylinder is used to place tea leaves; the receptacle includes a skeleton made of four stainless steels, the skeleton is equipped with a flower door that can be opened and closed, and the outer surface of the skeleton Covered with a screen; the center of the skeleton is provided with an electric heating device, the electric heating device includes an inner shell and an outer shell, the outer shell is set o...

Embodiment 3

[0037] The scenting equipment for jasmine tea processing in this embodiment includes a base, a cylinder is provided on the base, a gear ring is provided on the outer surface of the cylinder, a supporting roller and a driving motor are provided on the base, The output shaft of the drive motor is connected with a reducer, and the output shaft of the reducer is connected with a driving gear meshed with a gear ring; the inside of the cylinder is provided with a shelf for placing jasmine along the axial direction of the cylinder. Receptacle, the space between the receptacle and the cylinder is used to place tea leaves; the receptacle includes a skeleton made of four stainless steels, the skeleton is equipped with a flower door that can be opened and closed, and the outer surface of the skeleton Covered with a screen; the center of the skeleton is provided with an electric heating device, the electric heating device includes an inner shell and an outer shell, the outer shell is set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com