Fire extinguishing composition

A technology of fire extinguishing composition and fire extinguishing substance, which is applied in the direction of fire prevention equipment, etc. It can solve the problems of complex and bulky device structure, increase the quality of fire extinguishing agent, and reduce the use efficiency, and achieve good economy, shorten effective fire extinguishing time, and light structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

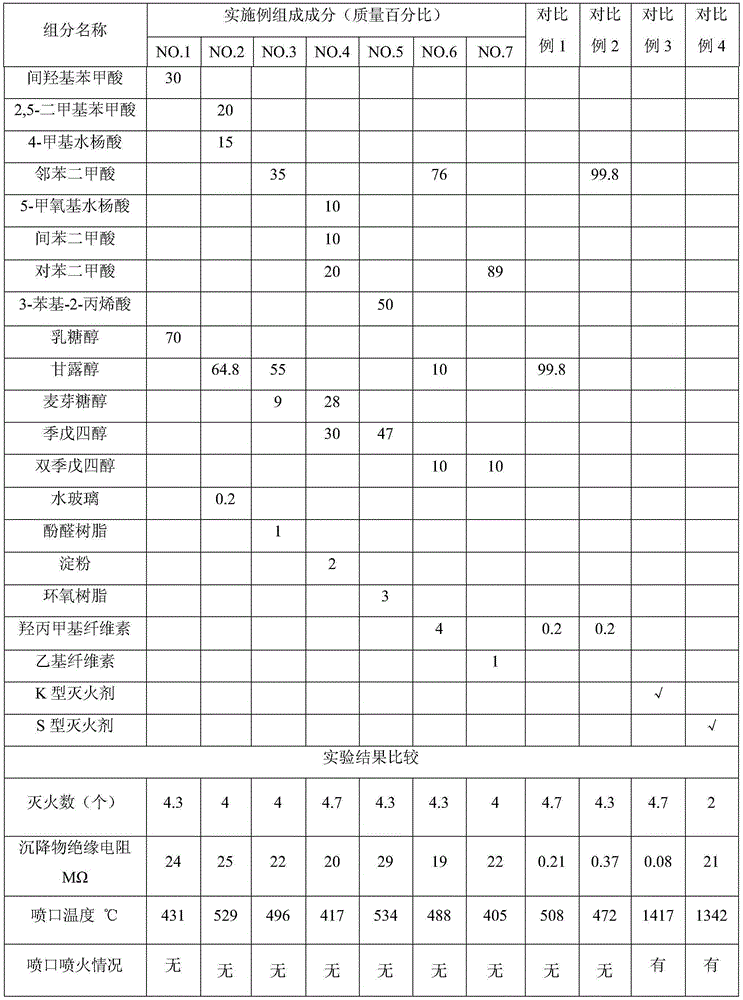

[0039] Fire extinguishing composition formula: m-hydroxybenzoic acid 30%, lactitol 70%

[0040] When in use, weigh 60g of the above-mentioned fire extinguishing agent and assemble it with 50g of aerosol generating agent at the same time. The fire extinguishing effect is shown in Table 1

Embodiment 2

[0042] Fire extinguishing composition formula: 20% 2,5-dimethylbenzoic acid, 15% 4-methyl salicylic acid, 64.8% mannitol, 0.2% water glass

[0043] When in use, weigh 60g of the above-mentioned fire extinguishing agent and assemble it with 50g of aerosol generating agent at the same time. The fire extinguishing effect is shown in Table 1

Embodiment 3

[0045] Fire extinguishing composition formula: phthalic acid 35%, mannitol 55%, maltitol 9%, phenolic resin 1%

[0046] When in use, weigh 60g of the above-mentioned fire extinguishing agent and assemble it with 50g of aerosol generating agent at the same time. The fire extinguishing effect is shown in Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com