Automatic pulse bag-type dust collector for treating dust-containing waste gas

A bag-type dust collector and exhaust gas treatment technology, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of insufficient efficiency and insufficient dust removal effect, and achieve simple production, good dust removal effect, and high performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

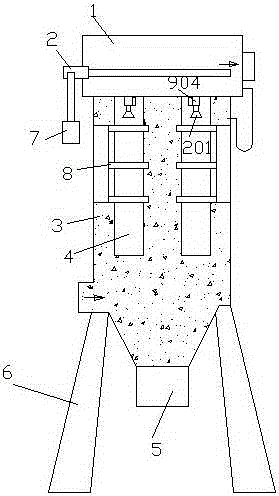

[0020] Embodiment 1: as figure 1 , 2 As shown, the automatic pulse bag filter for dusty waste gas treatment includes a clean air chamber 1, an air injection device 2 with a Venturi tube 201, a filter chamber 3, a filter bag 4 set in the filter chamber 3, Ash hopper 5, support 6 and PLC controller 7 connected with said air injection device 2, circular ring skeleton 8; The pipe is also provided with pulse valves, pipelines, etc. controlled by a PLC controller. Because it is a known structure, it will not be described here; in order to improve the dust removal effect and dust removal efficiency, we set the There is an elastic contraction mechanism 9 in contact with the filter bag 4, and the elastic contraction mechanism 9 can reduce the diameter of the filter bag.

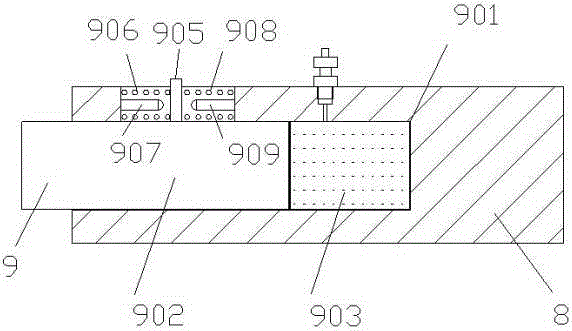

[0021] In this embodiment, the elastic contraction mechanism 9 includes a sliding groove 901 arranged in the ring frame 8, a sliding block 902 arranged in the sliding groove 901, and a sliding block 902 arranged at ...

Embodiment 2

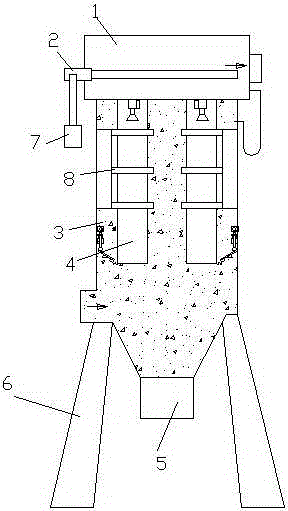

[0023] Embodiment 2, see attached image 3 , 4 In this embodiment, on the basis of Example 1, an auxiliary dust removal mechanism 10 is provided in the filter chamber 3 . The auxiliary dedusting mechanism 10 includes a support base 1001, a rotating plate 1002 hinged on the support base 1001, a fixed guide sleeve 1003, an impact rod 1004 arranged in the fixed guide sleeve 1003, an impact rod 1004 arranged in the impact rod 1004 The blocking ring 1005 on the top, the return spring 1006 set on the impact rod 1004 and between the fixed guide sleeve 1003 and the blocking ring 1005, the counterweight iron 1007 on one end of the rotating plate 1002 and one end The connecting soft rope 1008 connected to the bottom of the filter bag 4 and the other end connected to the counterweight iron 1007 and the impact part used to impact the impact rod 1004; the rotating plate is hinged through the hinge shaft and the support seat, fixed The guide sleeve is fixed on the side wall of the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com