Automatic corrosion preventing machine for PCCP pipes

An anti-corrosion machine and automatic technology, applied in the direction of spraying devices, etc., can solve the problems of low production efficiency, unguaranteed quality, unsafety, etc., and achieve the effect of smooth up and down movement, meeting practical needs, and stable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

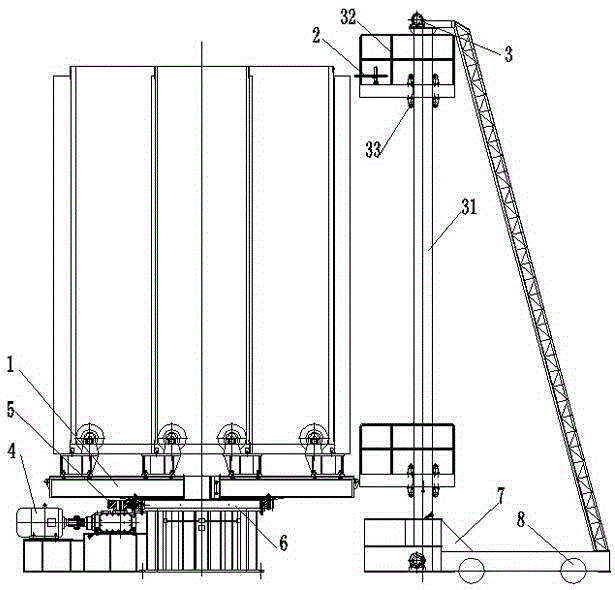

[0015] The present invention includes a main rotary table 1 for placing PCCP pipes and a lifting mechanism 3 for placing spray guns 2;

[0016] The main rotary table 1 is provided with a transmission mechanism to make it run, and the transmission mechanism includes a conical cylindrical gear reducer 5 driven by a frequency conversion motor 4, and then drives the main rotary table 1 to run through a slewing support 6.

[0017] Described elevating mechanism 3 comprises guide rail 31 that is vertically arranged, and described guide rail 31 is provided with the lifting platform 32 that can move up and down along guide rail 31, and described spray gun 2 is arranged on lifting platform 32; Described lifting platform 32 is controlled by frequency conversion. Motor 4, chain wheel drive up and down motion, and the guide wheel 33 that contacts with guide rail 31 is established on described lifting platform 32, and described lifting platform 32 is guided in and moves up and down along gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com