Material inspection device for assembly line and detection method thereof

An assembly line and material picking technology, which is applied in sorting and other directions, can solve the problems of inability to judge workpieces, increase production costs, and reduce production efficiency, so as to eliminate human eye fatigue, reduce production costs, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

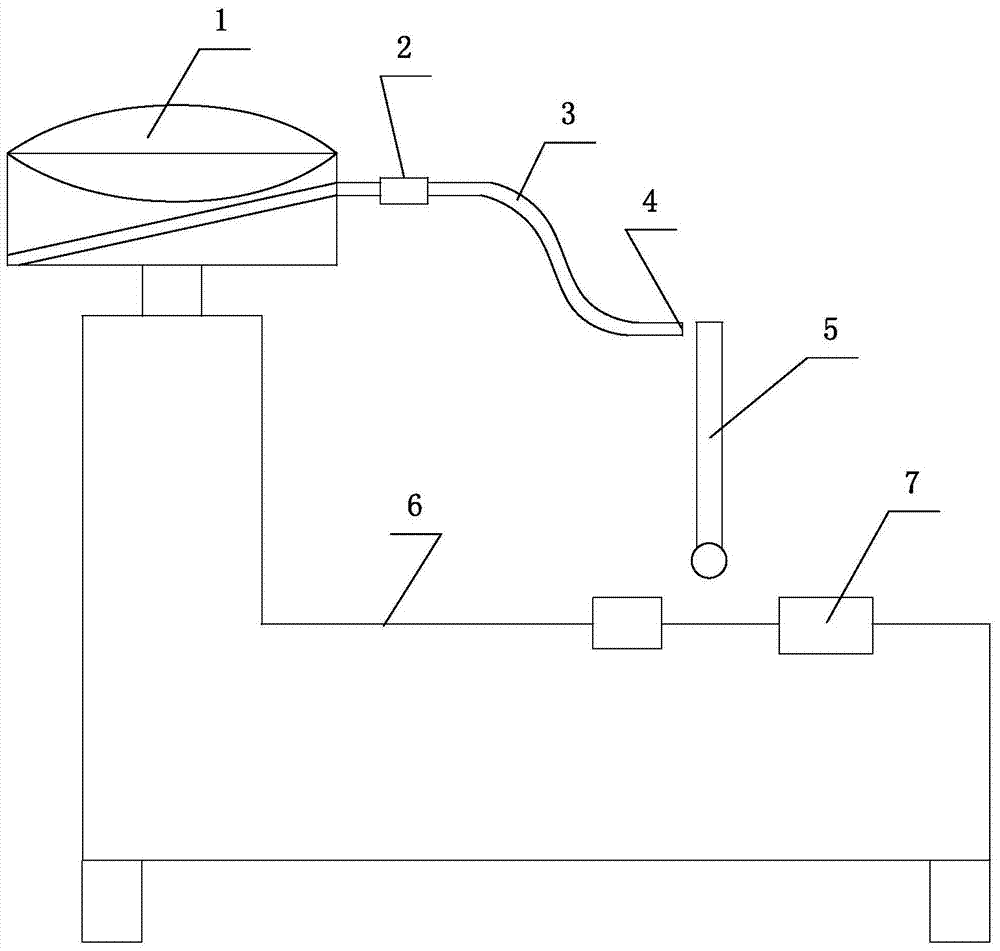

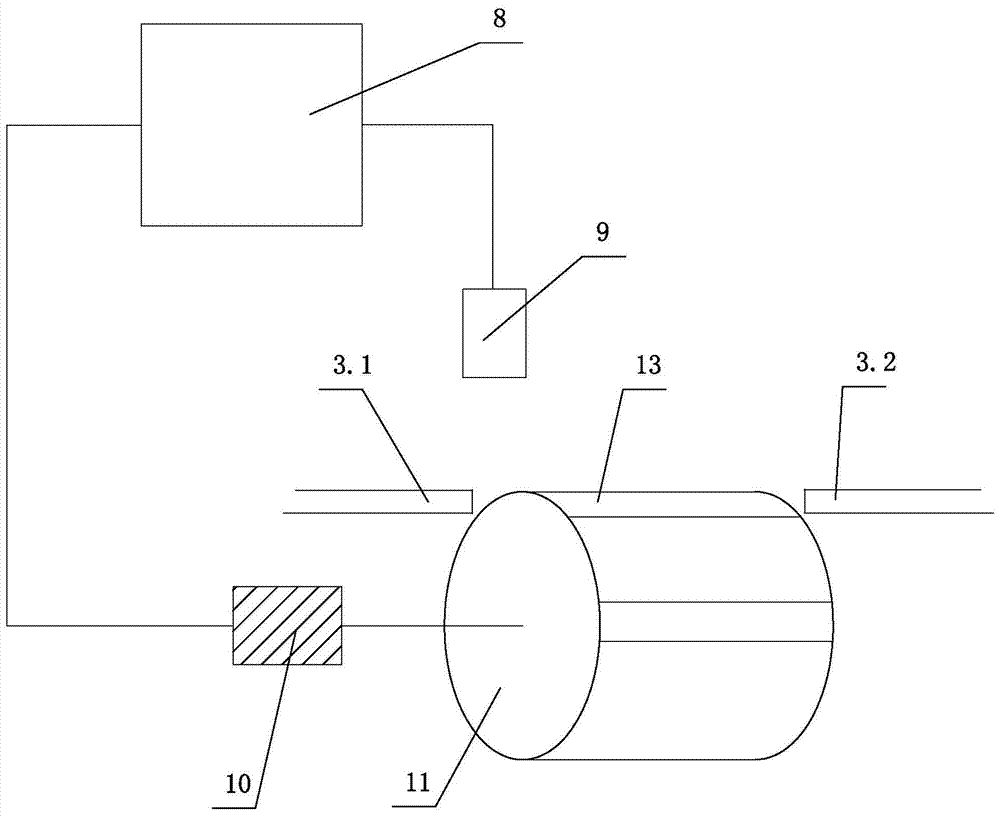

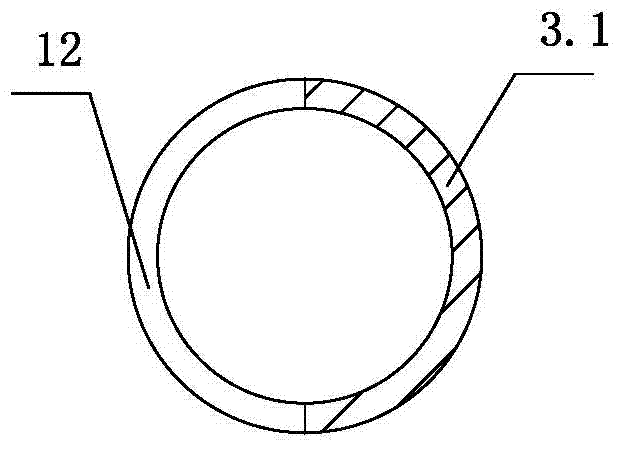

[0043] Depend on Figure 1 to Figure 5 It can be seen from the schematic structural diagram of the material picking device used in the assembly line of the present invention that it includes a vibrating plate 1 containing workpieces, a conveying guide rail 3 communicated with the output port of the vibrating disc 1, and a preset Feeding port 4. It also includes a first controller 8, a material picking device 2 and an image recognition detection device 9. The conveying guide rail 3 is divided into two disconnected sections, which are respectively the front guide rail 3.1 and the rear guide rail 3.2. The material picking device 2 Located between the front guide rail 3.1 and the rear guide rail 3.2. The image recognition detection device 9 includes a camera, the lens area of the camera covers the inspection device 2 , and the signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com