Tire installation/removal tool assembly and installation support tool

A technology for disassembling tools and tires, applied in tire installation, tire parts, transportation and packaging, etc., can solve problems such as increased control volume and complex design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

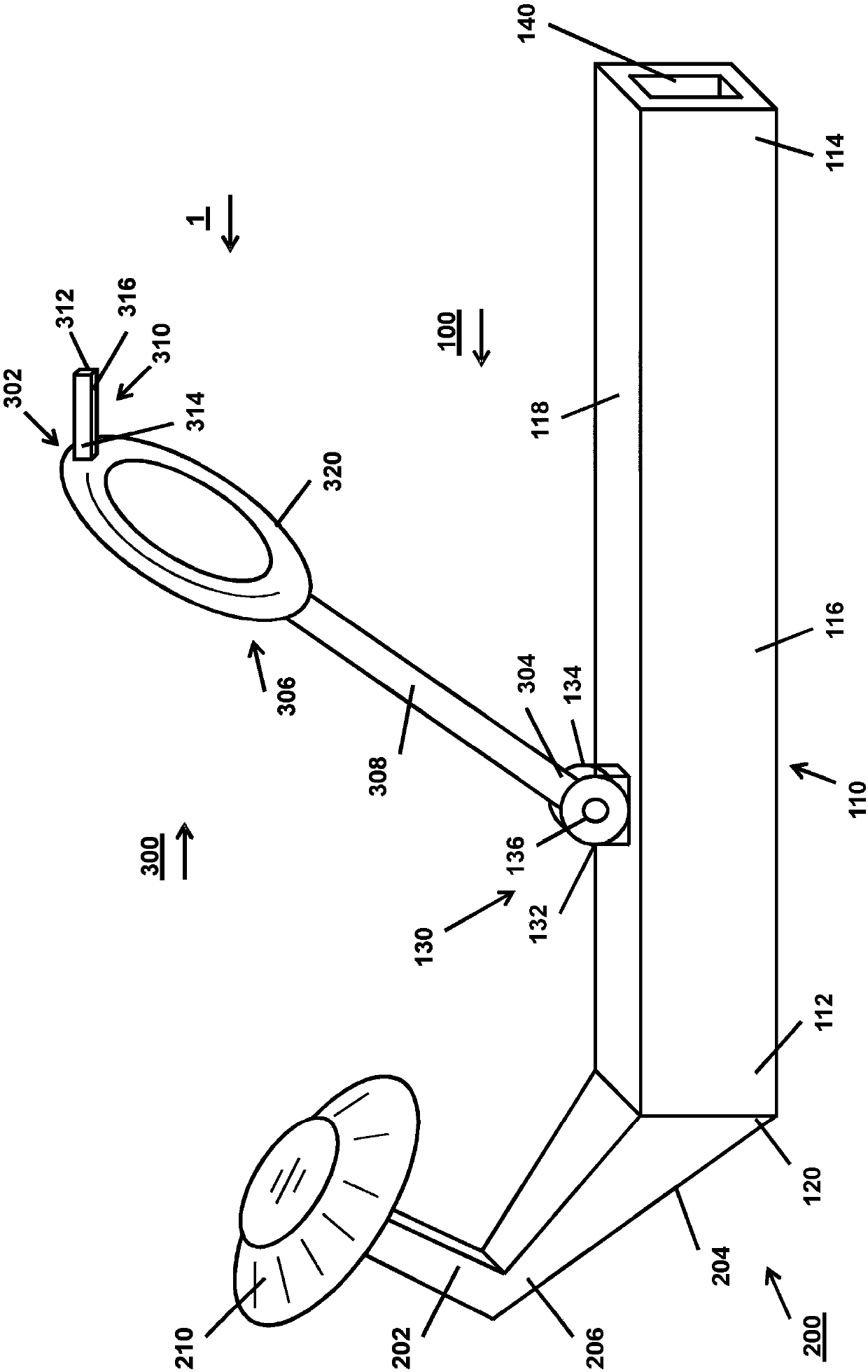

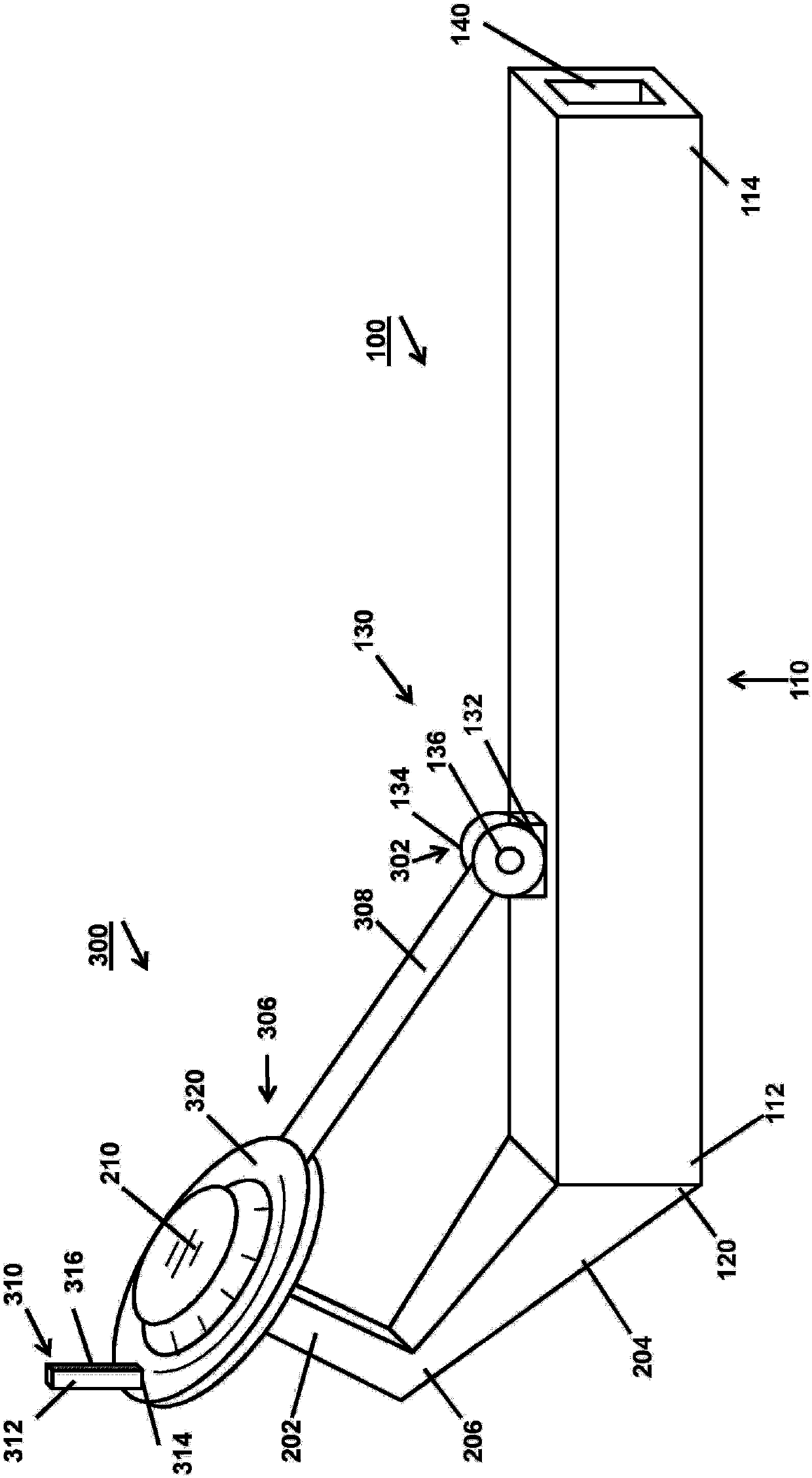

[0030] figure 1 is a schematic view of an embodiment of the installation / removal tool assembly 1 according to the invention with the installation support tool 300 in an inoperative position.

[0031] The mounting / removing tool assembly 1 includes a carrier unit 100 , a bead breaker tool 200 and a mounting support tool 300 .figure 1 , the bead breaker tool 200 is in its operative position and the installation support tool 300 is in its inoperative position.

[0032] Such as figure 1 As can be seen in FIG. 2 , the carrier unit 100 has a horizontally arranged bracket arm portion 110 having a first or left end 112 and a second or right end 114 , and a straight middle portion 116 . according to figure 1 The bracket arm portion 110 has a rectangular cross-section including a top surface 118, which may be made of steel.

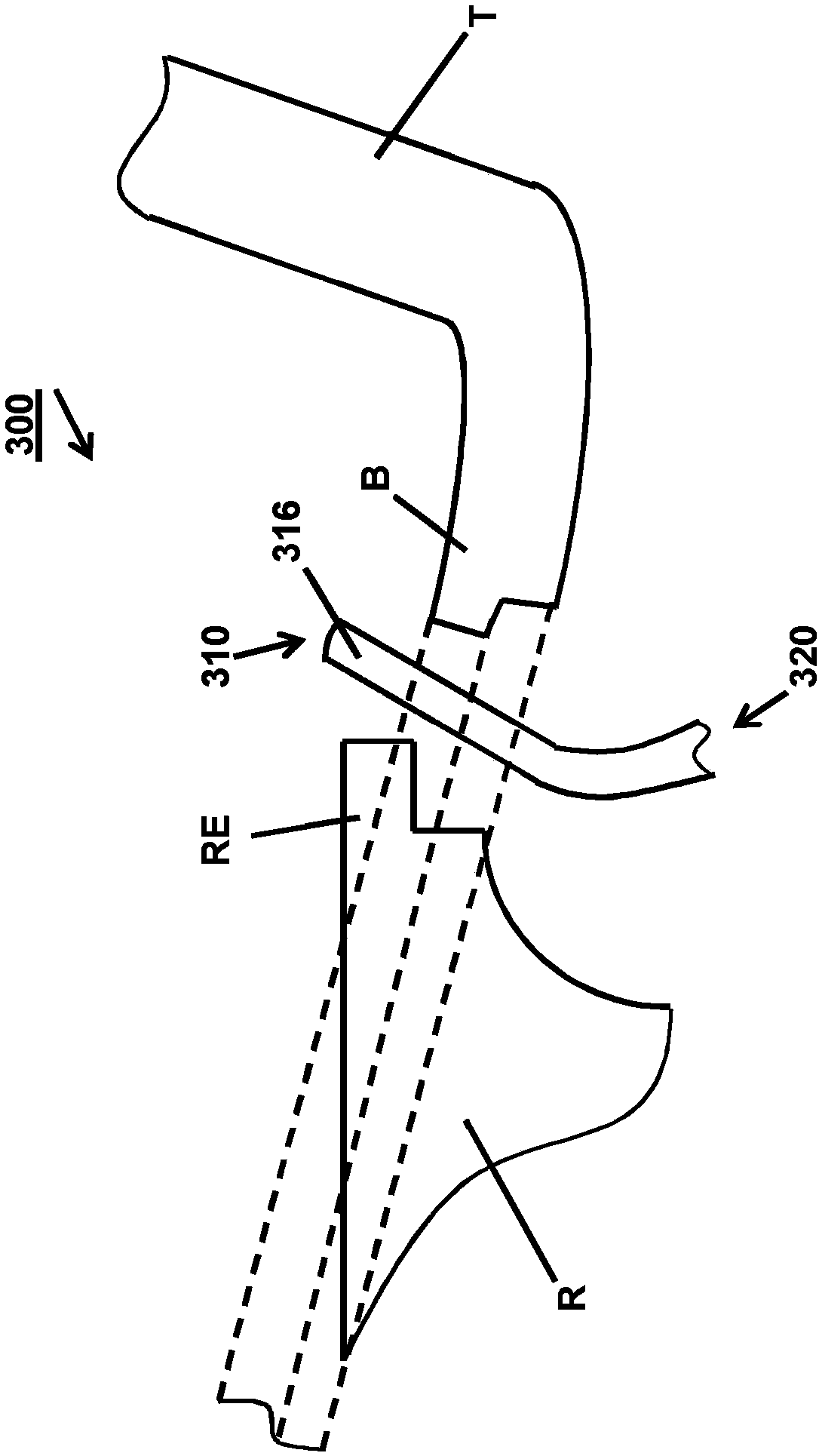

[0033] On the top surface 118 of the bracket arm portion 110, a second support means 130 for receiving the installation support tool 300 is provided. The suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com