Systems for managing downshifts in hybrid-electric vehicles

A hybrid electric and vehicle technology, which is applied in the arrangement of multiple different prime movers of hybrid vehicles and general power plants, and the use of engine-driven traction, etc., can solve the problems of complex operation mode transitions and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

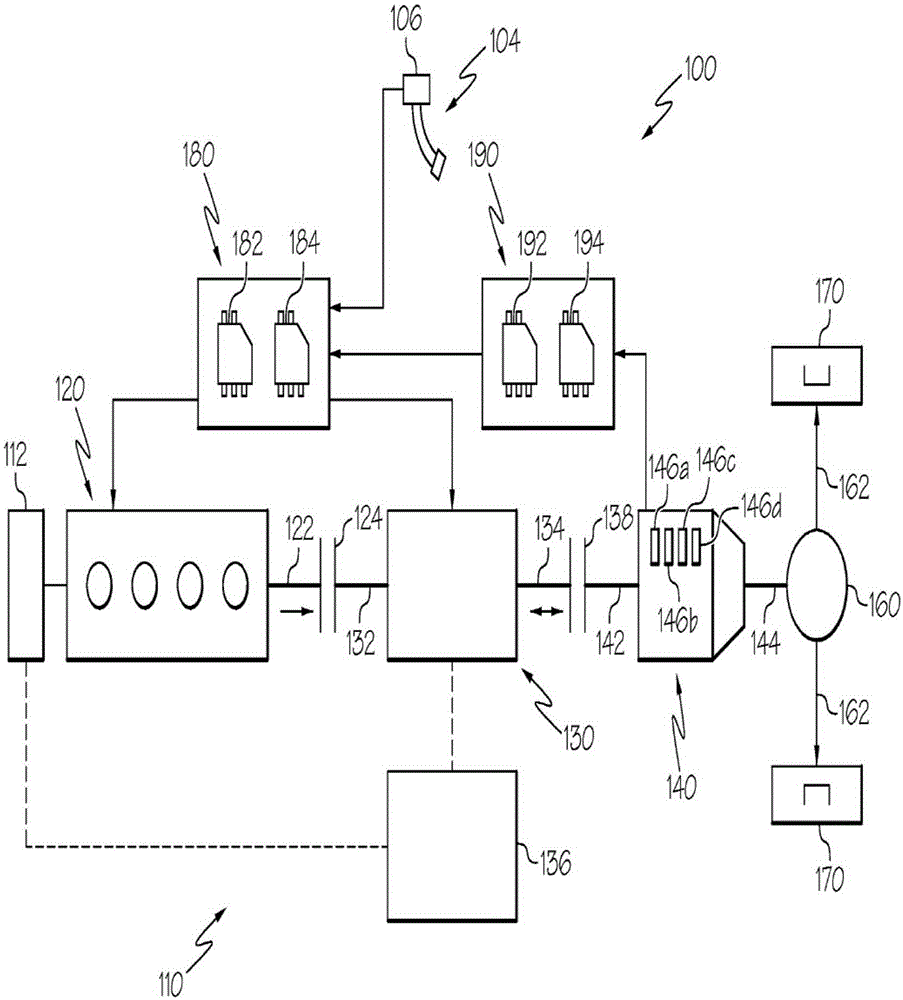

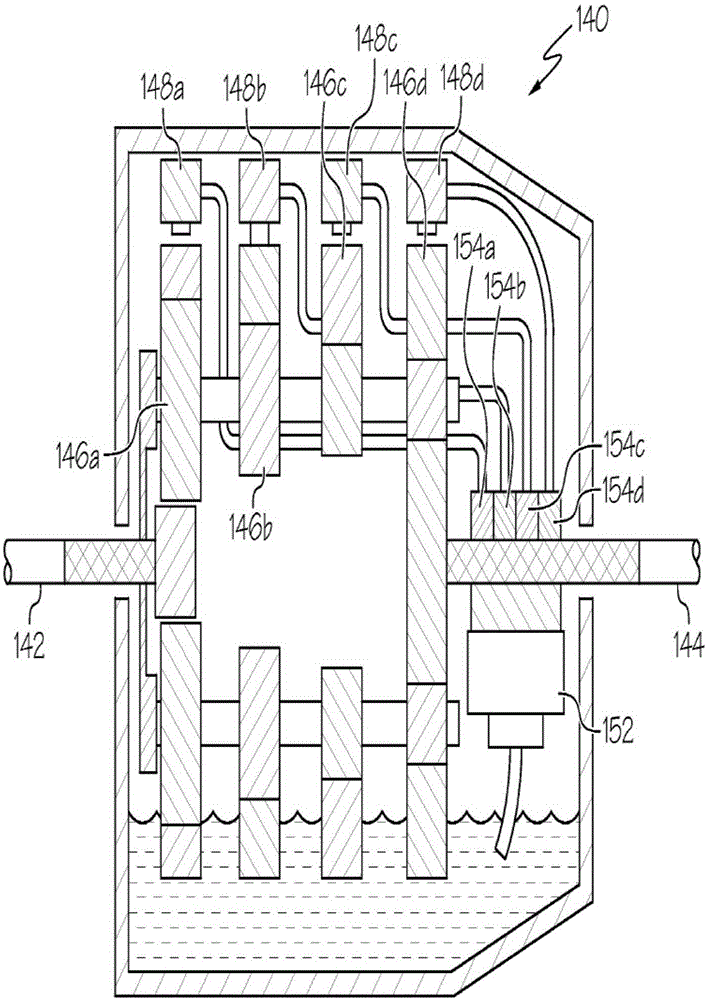

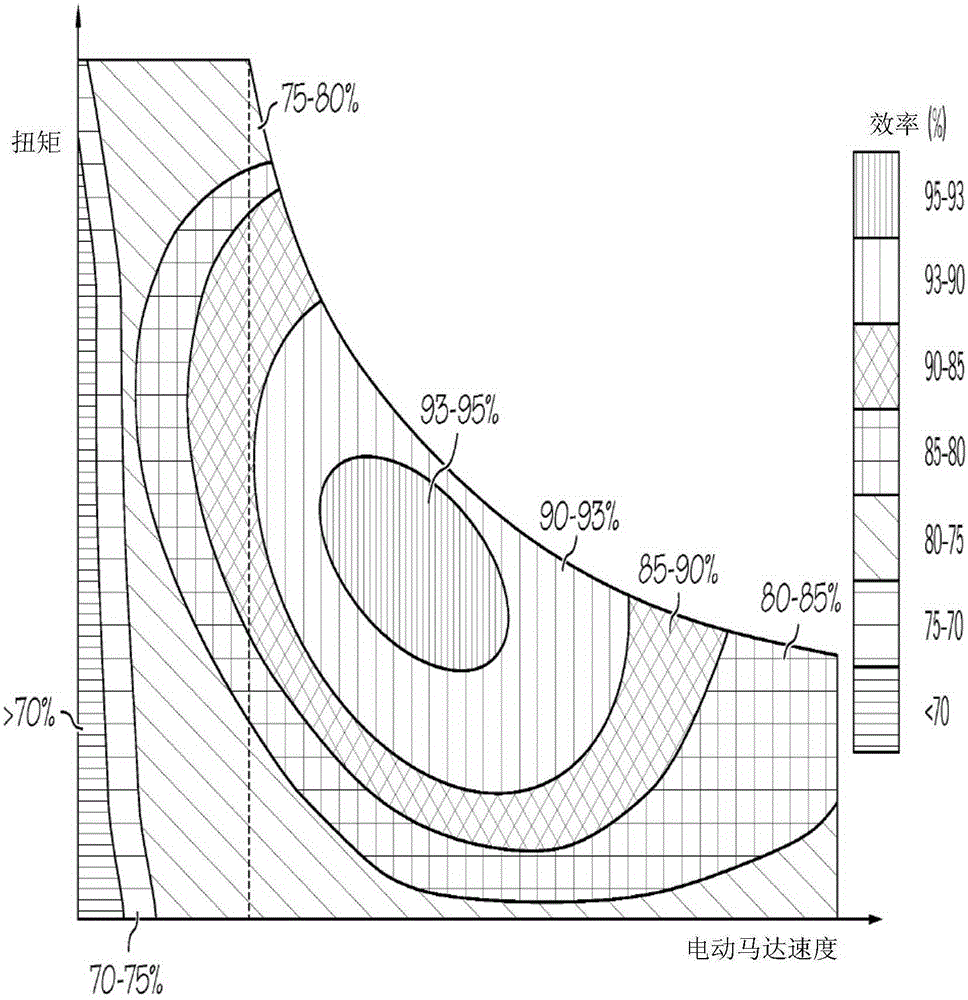

[0025] Reference will now be made in detail to an embodiment of a system for managing downshifting of a hybrid electric vehicle. The system includes a multi-speed transmission having a hydraulically-operated clutch that selectively engages gear sets and an input shaft, an internal combustion engine selectively coupled to the input shaft of the multi-speed transmission, and an internal combustion engine coupled to the input shaft of the multi-speed transmission electric motor. The system further includes an electronic control unit in electronic communication with the electric motor, components of the internal combustion engine, and a valve body of the multi-speed transmission that directs hydraulic fluid within the multi-speed transmission to effectuate shifts between the plurality of gear sets. When the hybrid electric vehicle is operating in an electric mode of operation and the driver requests increased torque, the electronic control unit evaluates the torque request and det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com