Swing-type robot arm and obstacle-surmounting method of overhead cable inspection robot

A line inspection robot and overhead cable technology, applied in the field of robotics, can solve problems such as time delay, and achieve the effect of improving load capacity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

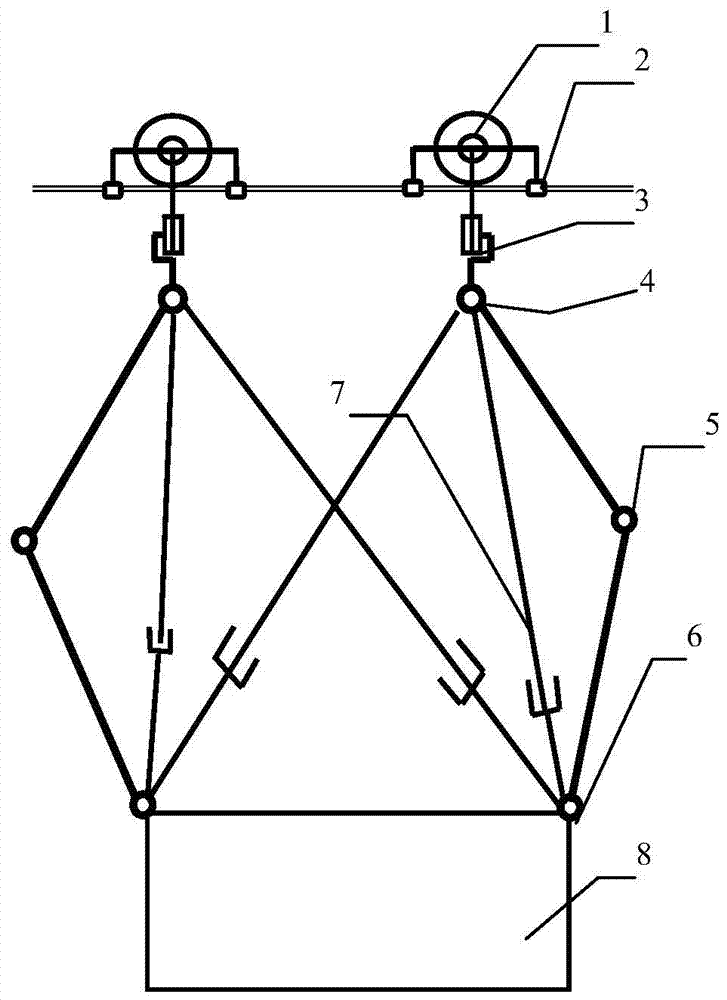

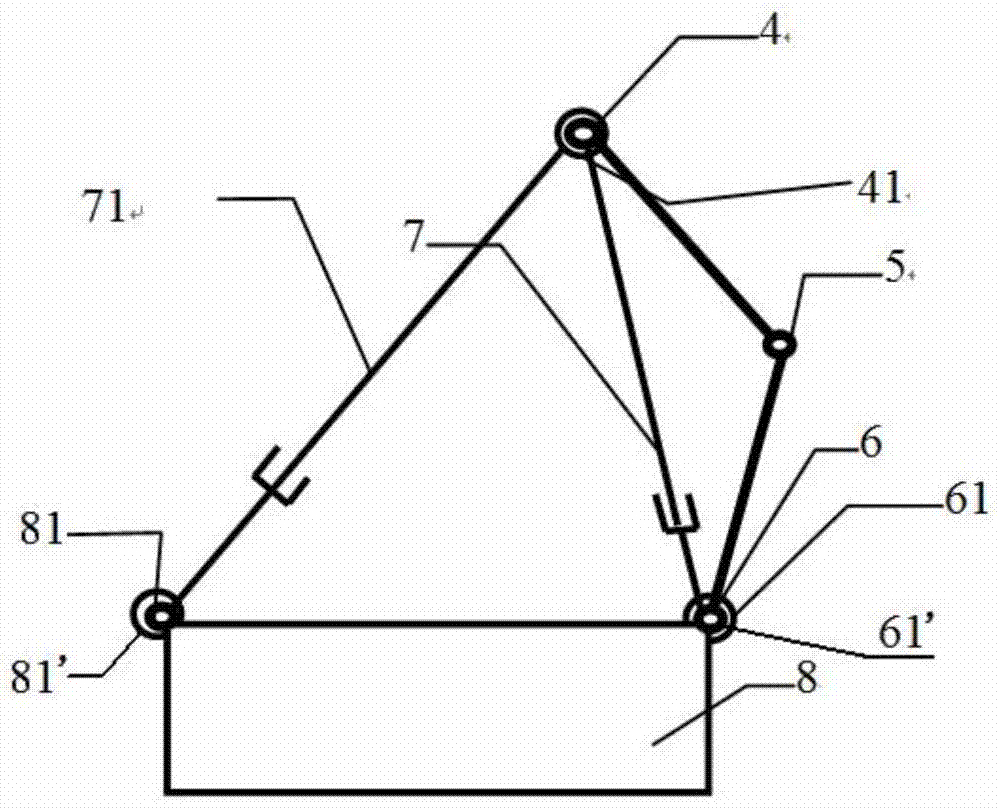

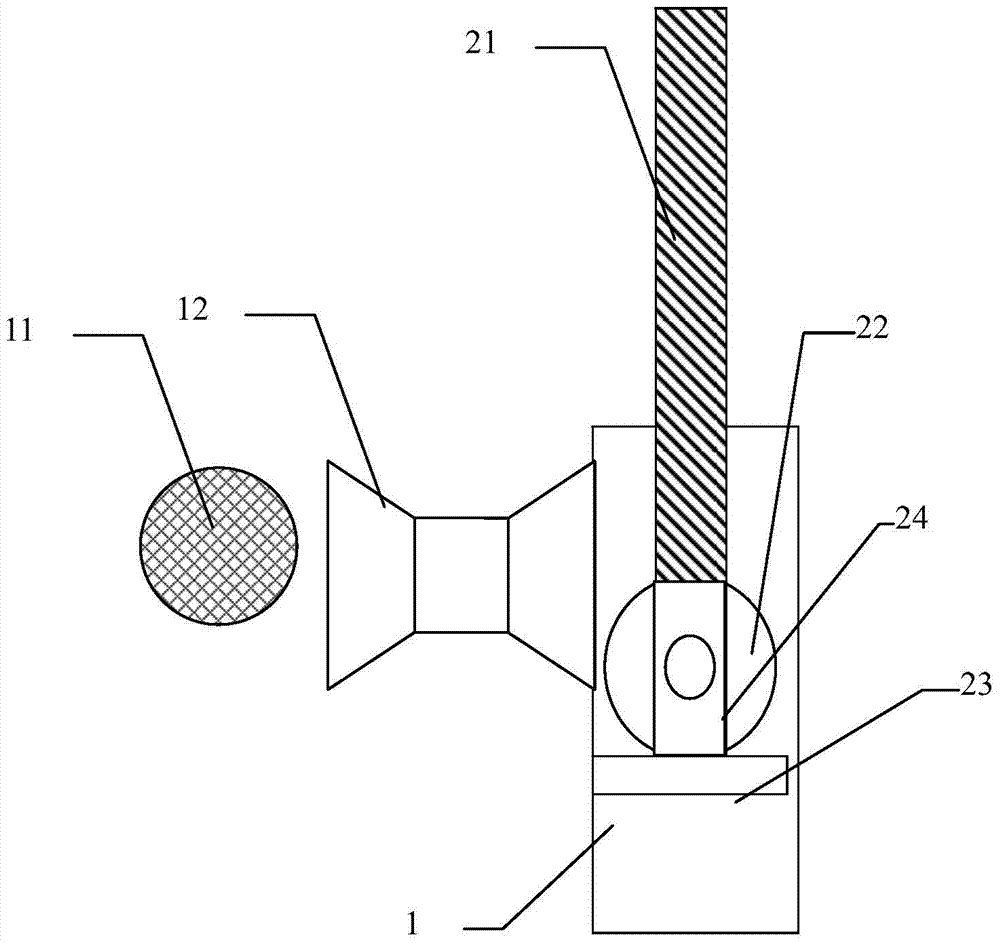

[0079] Such as figure 1 As shown, the overhead cable inspection robot in the present invention is mainly composed of a body 8, a pair of walking mechanisms 1, a pair of robotic arms and a control system. The pair of robotic arms are installed on both ends of the body, and the It can bear weight and can reach forward and grasp (relying on a pair of knuckles), and the control system can drive the walking mechanism and the robot arm to complete command actions (such as moving forward, stopping, fast threading and off-line, etc.); Comprise a horizontal rotation joint 3, a wrist joint 4, an elbow joint 5 and a shoulder joint 6 in each robot arm of the present invention, the main inventive point of the present invention is: be connected with flexible cable between each wrist joint and body two ends.

[0080] see figure 1 and figure 2 A fixed pulley 41 is provided at each wrist joint 4 of the swinging robot arm of the overhead cable inspection robot of the present invention; a pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com