A Modularly Combinable Miniature Venturi Type Bubble Generating Device

A bubble generating device, Venturi technology, applied in mixers, mixing methods, transportation and packaging, etc., can solve the problem of limited ability to prepare bubbles, achieve uniform size, ensure consistency, and meet the requirements of equipment use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The main content of the present invention is further illustrated below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

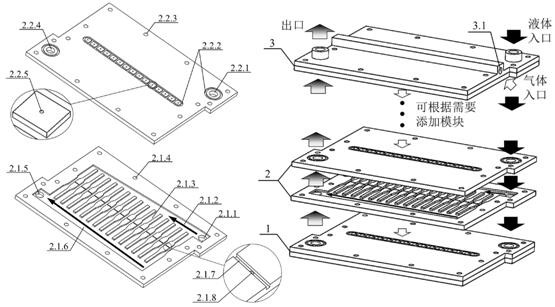

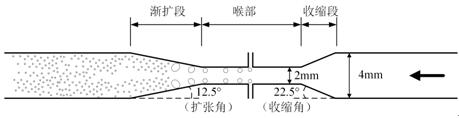

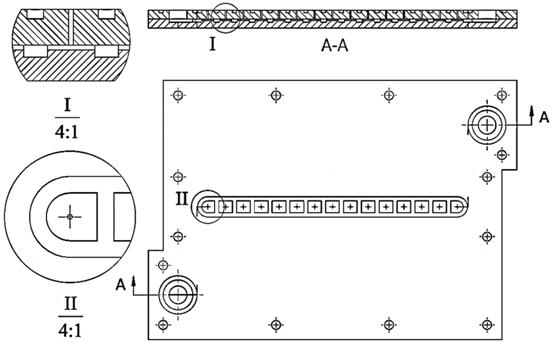

[0022] The invention discloses a modularly combinable miniature Venturi-type bubble generating device, which comprises a bottom module (1), a middle module (2) and a top module (3), and each middle module includes a flow-distributing bottom plate and an upper cover plate. Among them, the distribution bottom plate mainly includes the module liquid outlet hole (2.1.1), the liquid flow channel (2.1.2), the micro Venturi channel (2.1.3), the gas-liquid mixture outlet hole (2.1.5), the module outlet Flow channel (2.1.6), throat air intake slot (2.1.7), throat air outlet (2.1.8), the upper cover mainly includes the module liquid inlet (2.2.1), sealing groove (2.2.2 ), gas-liquid mixture outlet (2.2.4), throat inlet (2.2.5). Each module has 16 micro Venturi channels (2.1.3) processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com