Separated type cloth spreading net

A separate and spread technology, applied in the direction of winding strip, thin material processing, transportation and packaging, can solve the problems of difficult processing, long length, heavy overall weight, etc., to reduce the difficulty of surface treatment and easy to use. The effect of convenience and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

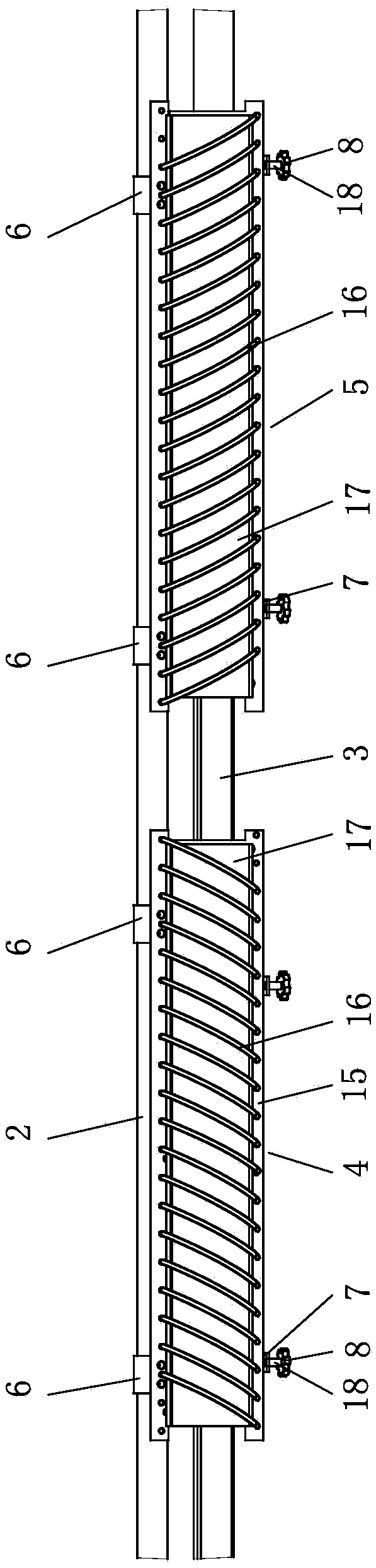

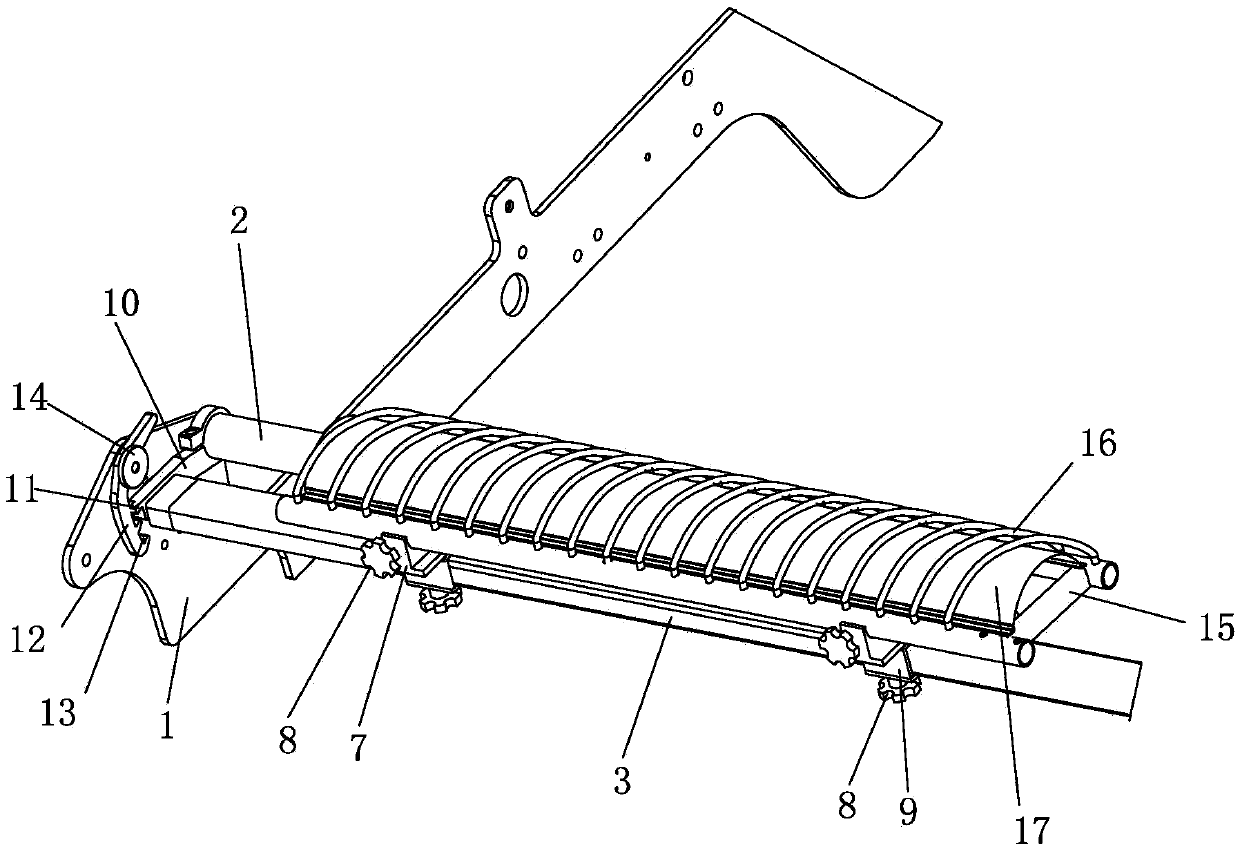

[0021] The present invention will be further described below with specific examples, see figure 1 -2:

[0022] A separated spreading net includes a left cloth table wall 1 and a right cloth table wall. A rotating shaft 2 is arranged between the left cloth table wall 1 and the right cloth table arm, and a spreader is arranged on one side of the rotating shaft 2. The cloth net support arm 3, the spread net support arm 3 is also located between the left cloth table wall 1 and the right cloth table arm. The spreading net support arm 3 is connected to the rotating shaft 2 through a transfer mechanism, and the spreading net support arm 3 is linked with the rotating shaft 2 through the transfer mechanism, that is, the rotating shaft 2 rotates, and at the same time drives the spreading net support arm 3 to rotate around Shaft 2 axis rotation. The adapter mechanism is connected with the inclination adjustment mechanism. The inclination adjustment mechanism is arranged on the left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com