Electric block type double-rail and single-main-beam crane

An electric hoist, double-track single technology, applied in the direction of travel mechanism, support structure, load hanging components, etc., can solve the problem of affecting the service life and working efficiency of electric hoist, not making full use of the height space of the workplace, affecting the lifting height of the crane and Work efficiency and other issues, to achieve the effect of being conducive to automatic welding operations, easy to ensure welding quality, improve lifting performance and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

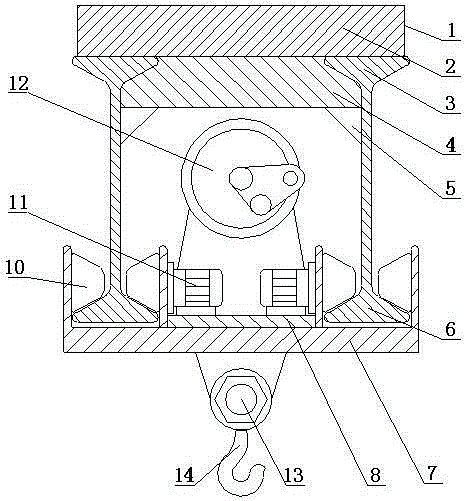

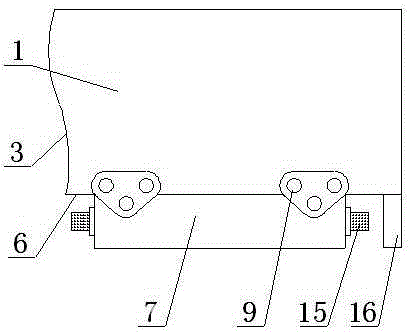

[0019] like figure 1 and figure 2 As shown, an electric hoist-type double-rail single-girder crane includes a main beam 1, an upper wing plate 2 is welded on the top of the main beam 1, and webs are welded at both ends of the upper wing plate 2 respectively. plate 3, the lower end of the web 3 is provided with a driving track 6, the upper wing reinforcement plate 4 is welded between the upper wing plate 2 and the web 3, and the upper wing reinforcement plate 4 and the web 3 are welded with a web stiffener 5, and an electric hoist 12 is installed inside the main beam 1, and the electric hoist 12 is connected with an electric hoist base 8, and the electric hoist The lower part of the gourd base 8 is connected with a trolley frame 7, and the trolley frame 7 is equipped with a traveling device 9, and the interior of the traveling device 9 is equipped with a traveling wheel 10, and the traveling wheel 10 is connected with a drive motor 11 , the electric hoist 12 is connected wit...

Embodiment 2

[0022] like figure 1 and figure 2 As shown, an electric hoist-type double-rail single-girder crane includes a main beam 1, an upper wing plate 2 is welded on the top of the main beam 1, and webs are welded at both ends of the upper wing plate 2 respectively. plate 3, the lower end of the web 3 is provided with a driving track 6, the upper wing reinforcement plate 4 is welded between the upper wing plate 2 and the web 3, and the upper wing reinforcement plate 4 and the web 3 are welded with a web stiffener 5, and an electric hoist 12 is installed inside the main beam 1, and the electric hoist 12 is connected with an electric hoist base 8, and the electric hoist The lower part of the gourd base 8 is connected with a trolley frame 7, and the trolley frame 7 is equipped with a traveling device 9, and the interior of the traveling device 9 is equipped with a traveling wheel 10, and the traveling wheel 10 is connected with a drive motor 11 , the electric hoist 12 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com