A concrete reinforcement additive

A technology for reinforcing additives and concrete, applied in the field of concrete reinforcing additives, can solve problems such as cost waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

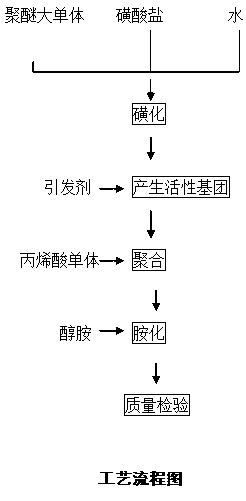

Method used

Image

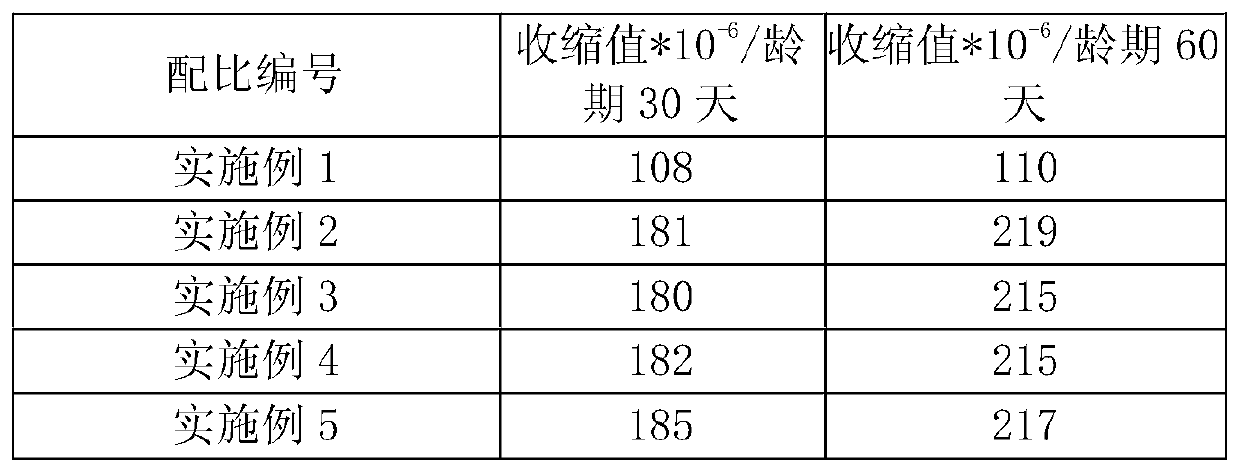

Examples

Embodiment 1

[0024] Concrete reinforcement additive, which is prepared by the following method:

[0025] Add polyether macromonomer and sulfonate in water, raise the temperature to 60 degrees, sulfonate for half an hour, add initiator, add acrylic acid monomer dropwise while stirring, control the dropping time at 0.5 hour, keep the temperature for one hour after dropping, Cool down to 45 degrees, add alcohol amine dropwise, control the dropping time within 1 hour, and keep the temperature for one hour to complete the finished product.

[0026] The mass ratio of described sulfonate and polyether macromonomer is 1:3,

[0027] The mass ratio of the initiator to the polyether macromonomer is 1:3.

[0028] An environmentally friendly colorless transparent liquid (odorless, non-toxic, non-flammable) is obtained.

[0029] The hard insoluble matter generated by the reaction of this product can fill and block the capillary pores in the concrete, increase the compactness inside the concrete and im...

Embodiment 2

[0031] Concrete reinforcement additive, which is prepared by the following method:

[0032] Add polyether macromonomer and sulfonate in water, heat up 60 degrees, sulfonate for half an hour, add initiator, add acrylic acid monomer dropwise while stirring, control the dropping time in 1 hour, keep the temperature for one hour after dropping, Cool down to 45 degrees, add alcohol amine dropwise, control the dropping time at 0.5 hour, and keep the temperature for one hour after dropping to get the finished product.

[0033] An environmentally friendly colorless transparent liquid (odorless, non-toxic, non-flammable) is obtained.

[0034] The mass ratio of described sulfonate and polyether macromonomer is 1:3.5,

[0035] The mass ratio of the initiator to the polyether macromonomer is 1:2.5.

[0036] The hard insoluble matter generated by the reaction of this product can fill and block the capillary pores in the concrete, increase the compactness inside the concrete and improve t...

Embodiment 3

[0038] Concrete reinforcement additive, which is prepared by the following method:

[0039] Add polyether macromonomer and sulfonate in water, raise the temperature to 60 degrees, sulfonate for half an hour, add the initiator, add acrylic acid monomer dropwise while stirring, control the dropping time at 0.6 hours, keep the temperature for one hour after dropping, Cool down to 45 degrees, add alcohol amine dropwise, control the dropping time at 0.9 hours, and keep the temperature for one hour after dropping to get the finished product.

[0040] The mass ratio of described sulfonate and polyether macromonomer is 1:3.1,

[0041] The mass ratio of the initiator to the polyether macromonomer is 1:2.9.

[0042] An environmentally friendly colorless transparent liquid (odorless, non-toxic, non-flammable) is obtained.

[0043]The hard insoluble matter generated by the reaction of this product can fill and block the capillary pores in the concrete, increase the compactness inside th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com