A kind of anti-clay type naphthalene series water reducing agent and preparation method thereof

A naphthalene-based water-reducing agent and anti-clay technology, which is applied in the field of clay-resistant naphthalene-based water-reducing agent and its preparation, can solve the problems of water-reducing performance reduction and achieve the effect of reducing negative impact and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

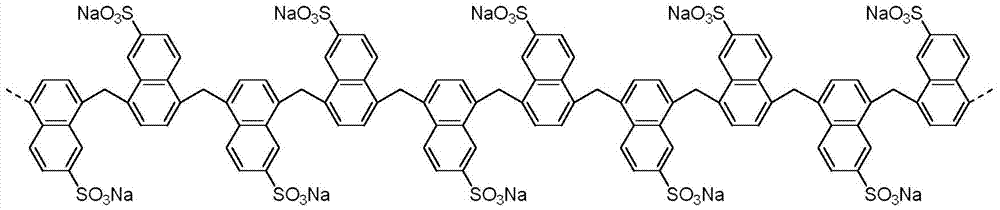

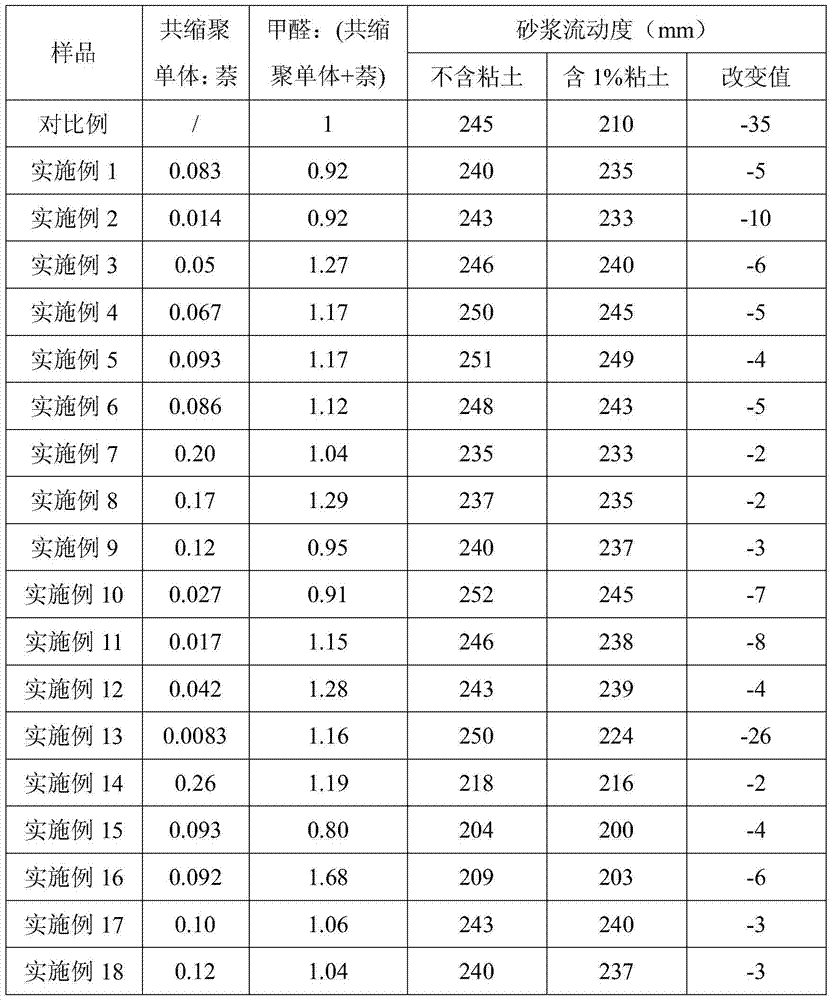

[0036] A clay-resistant naphthalene-based water reducer, the preparation steps of which are as follows:

[0037] (1) Sulfonation: Heat and melt 162kg (1.2kmol) of 95% naphthalene to 140°C, add 180kg (1.8kmol) of 98% concentrated sulfuric acid, and sulfonate at 165±3°C for 2.5 hours;

[0038] (2) Hydrolysis: cool down to 120°C, add 50kg of water, and hydrolyze for 1 hour;

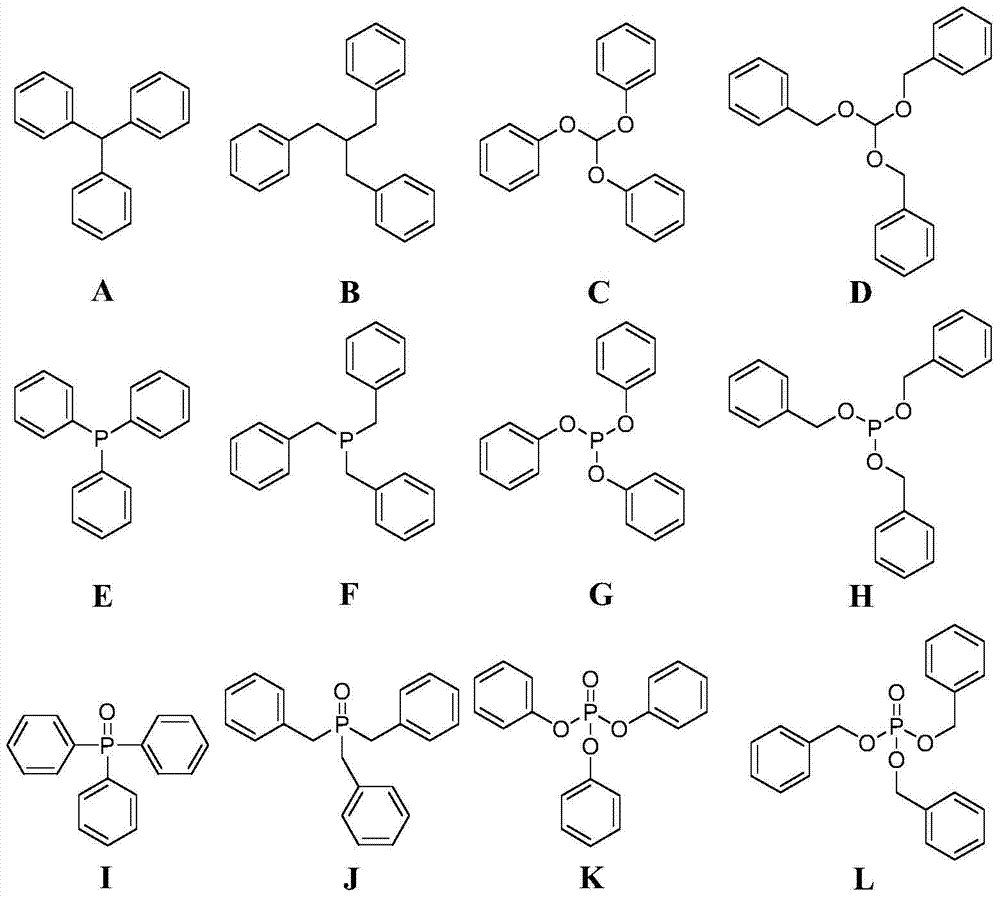

[0039] (3) Condensation: cool down to 95°C, add 24.4kg (0.1kmol) of triphenylmethane, then add 97kg (1.2kmol) of 37% formaldehyde solution, and carry out condensation reaction at 100±3°C for 5.5 hours;

[0040] (4) Neutralization: add 32% sodium hydroxide solution, neutralize the reactant to a pH value of 7-8, and obtain the product.

Embodiment 2

[0042] A clay-resistant naphthalene-based water reducer, the preparation steps of which are as follows:

[0043] (1) Sulfonation: Heat and melt 187kg (1.4kmol) of 96% naphthalene to 130°C, add 178kg (1.8kmol) of 99% concentrated sulfuric acid, and react for sulfonation at 150±3°C for 3.5 hours;

[0044] (2) Hydrolysis: cool down to 105°C, add 140kg of water, and hydrolyze for 1 hour;

[0045] (3) Condensation: cool down to 100°C, add 5.7kg (0.02kmol) of tribenzylmethane, then add 105kg (1.3kmol) of 37% formaldehyde solution, and carry out condensation reaction at 98±3°C for 6 hours;

[0046](4) Neutralization: add 32% sodium hydroxide solution, neutralize the reactant to a pH value of 7-8, and obtain the product.

Embodiment 3

[0048] A clay-resistant naphthalene-based water reducer, the preparation steps of which are as follows:

[0049] (1) Sulfonation: Heat and melt 162kg (1.2kmol) of 95% naphthalene to 140°C, add 190kg (1.9kmol) of 98% concentrated sulfuric acid, and react for sulfonation at 150±3°C for 3.5 hours;

[0050] (2) Hydrolysis: cool down to 135°C, add 70kg of water, and hydrolyze for 1.5 hours;

[0051] (3) Condensation: cool down to 105°C, add 17.5kg (0.06kmol) of tris(phenoxy)methane, then add 130kg (1.6kmol) of 37% formaldehyde solution, and carry out condensation reaction at 105±3°C for 5 hours;

[0052] (4) Neutralization: add 32% sodium hydroxide solution, neutralize the reactant to a pH value of 7-8, and obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com