Low relative molecular weight anti-clay type phosphoric acid-based superplasticizer, its preparation method and use

A superplasticizer and molecular weight technology, applied in the field of concrete admixtures, can solve the problems of difficult process control, cumbersome operation steps, and unsatisfactory effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

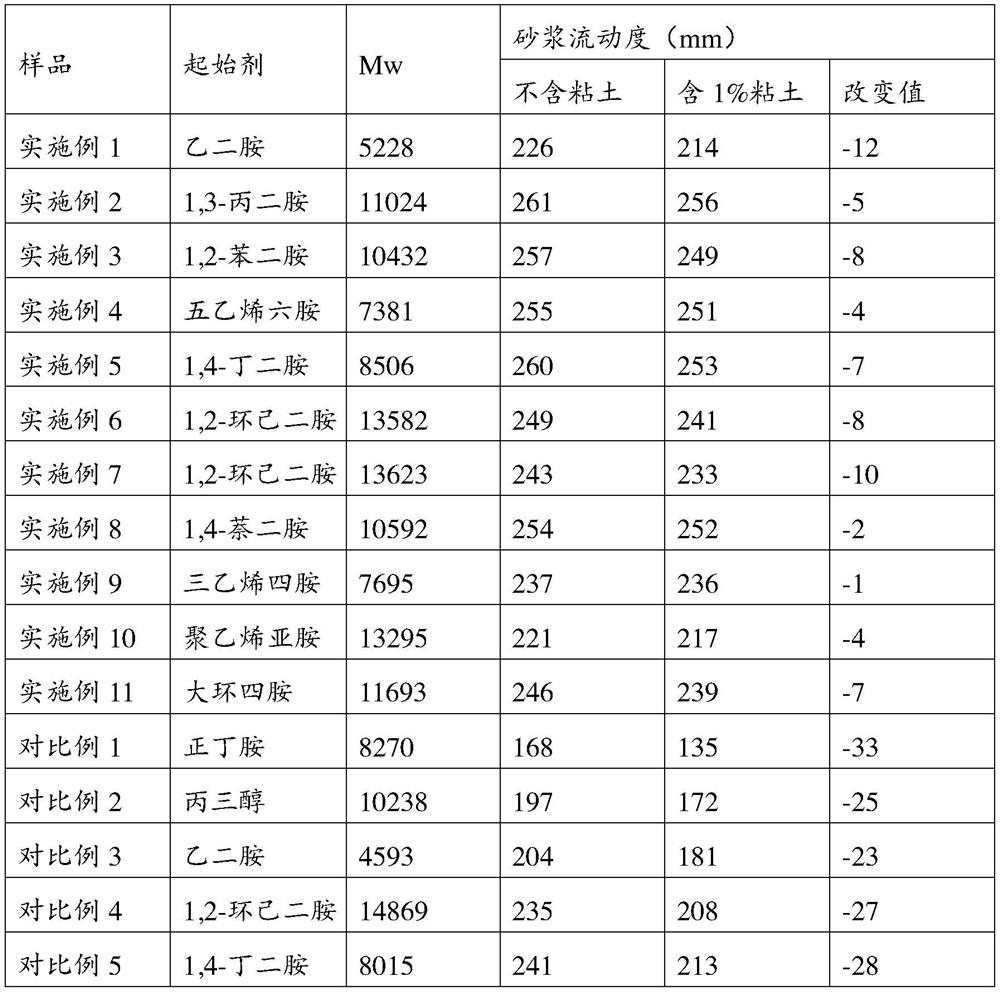

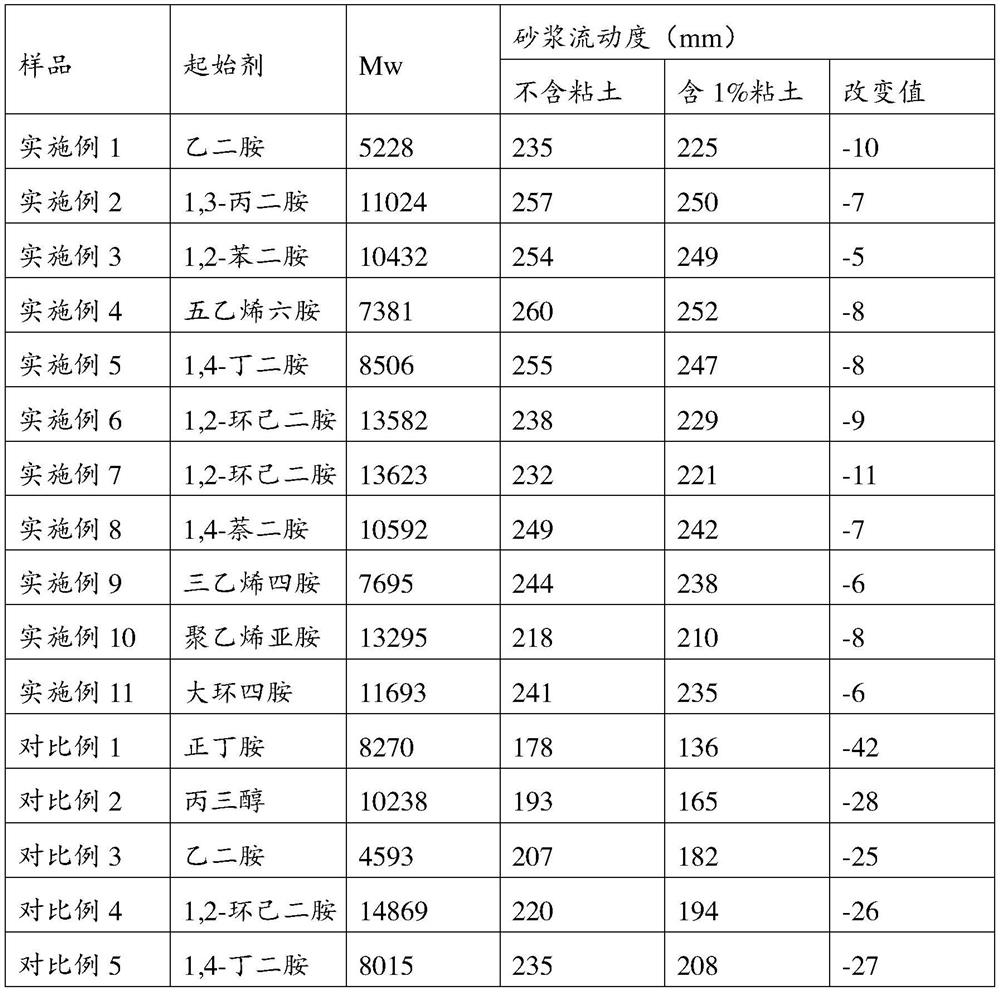

Examples

Embodiment 1

[0048] Branched polyether polyamine, the synthesis initiator is ethylenediamine, the polymerization monomer is ethylene oxide, and the catalyst NaH (60wt%) addition (in terms of 100% purity) is 0.8% of the amount of ethylenediamine . Weigh 0.1 mol (6.0 g) of ethylenediamine, 11.3 mol (497.2 g) of ethylene oxide, and 32 mg of catalyst NaH (60 wt %). Add the above-mentioned initiator ethylenediamine and catalyst into a closed reaction kettle, evacuate to -0.1MPa, feed 20g of ethylene oxide, raise the temperature to 110°C to initiate the reaction and continue to feed the remaining ethylene oxide, keep the temperature for the reaction After 1 h, the volatile matter was removed under reduced pressure, and the insoluble matter was removed by filtration to obtain a branched polyether polyamine intermediate.

[0049] Branched polyether polyamine intermediate alcohol hydroxyl group (0.4mol) / phosphorylation reagent molar ratio is 1:1.05, weigh 5.1g NKC-9 and 49.6g (0.42mol) 85% phospho...

Embodiment 2

[0051] For the branched polyether polyamine, the synthetic initiator is 1,3-propylenediamine, the polymerization monomer is ethylene oxide, and the amount of catalyst sodium hydroxide added is 1.5% of the amount of 1,3-propylenediamine. Weigh 0.1 mol (7.4 g) of 1,3-propylenediamine, 24.7 mol (1086.8 g) of ethylene oxide, and 60 mg of catalyst sodium hydroxide. Add the above-mentioned initiator 1,3-propylenediamine and catalyst into a closed reaction kettle, vacuumize to -0.1MPa, feed 20g of ethylene oxide, raise the temperature to 110°C to initiate the reaction and continue to feed the remaining ethylene oxide alkane, keep warm for 3 hours, remove volatile substances under reduced pressure, and remove insoluble substances by filtration to obtain a branched polyether polyamine intermediate.

[0052] Branched polyether polyamine intermediate alcoholic hydroxyl group (0.4mol) / phosphorylation reagent molar ratio is 1:1.05, weigh 10.9g Amberlyst-15 and 49.6g (0.42mol) 85% phosphori...

Embodiment 3

[0054] For the branched polyether polyamine, the synthetic initiator is 1,2-phenylenediamine, the polymerization monomer is propylene oxide, and the amount of catalyst Na added is 1.6% of the amount of 1,2-phenylenediamine. 0.1 mol (10.8 g) of 1,2-phenylenediamine, 17.5 mol (1016.4 g) of propylene oxide, and 37 mg of catalyst Na were weighed. Add the above-mentioned initiator 1,2-phenylenediamine and the catalyst into the closed reaction kettle, evacuate to -0.1MPa, pass in 20g of propylene oxide, raise the temperature to 110°C to initiate the reaction and continue to pass in the remaining propylene oxide, Keeping the reaction for 5 hours, removing volatile substances under reduced pressure, and removing insoluble substances by filtration to obtain a branched polyether polyamine intermediate.

[0055] Branched polyether polyamine intermediate alcoholic hydroxyl group (0.4mol) / phosphorylation reagent molar ratio is 1:1.1, weigh 20.5g NKC-9 and 82.1g (0.44mol) 76% polyphosphoric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com