Preparation method and application of a new type of anti-soil phosphoric acid-based superplasticizer

A superplasticizer, phosphoric acid-based technology, applied in the field of concrete admixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

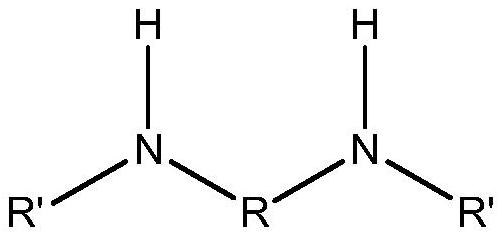

Method used

Image

Examples

Embodiment 1

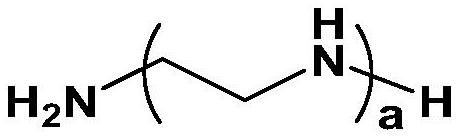

[0055] For the branched polyether polyamine, the synthesis initiator is ethylenediamine, the polymerization monomer is ethylene oxide, and the addition amount of the catalyst NaH (wt60%) is 0.8% of the substance quality of the ethylenediamine. Weigh 0.1 mol (6.0 g) of ethylenediamine, 3 mol (132 g) of ethylene oxide, and 32 mg of catalyst NaH (60% by weight). Add the above-mentioned initiator ethylenediamine and catalyst into a closed reaction kettle, evacuate to -0.1MPa, feed 20g of ethylene oxide, raise the temperature to 110°C to initiate the reaction and continue to feed the remaining ethylene oxide, keep the temperature for the reaction After 1 h, the volatile substances were removed under reduced pressure to obtain a branched polyether polyamine intermediate.

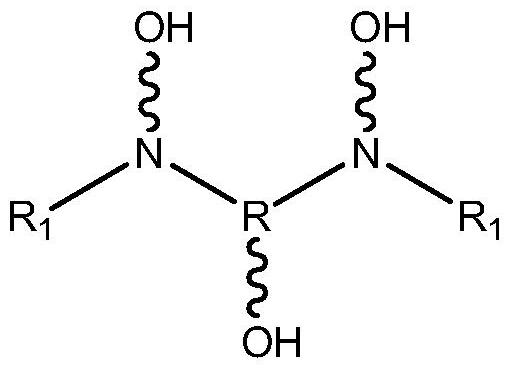

[0056] Add the branched polyetheramine intermediate synthesized above, 0.22mol (20.35g) of epichlorohydrin, 0.0018mol (0.31g) of potassium sulfate, and 56g of solvent water into the reaction kettle, stir evenly, a...

Embodiment 2

[0058] For the branched polyether polyamine, the synthetic initiator is 1,3-propylenediamine, the polymerization monomer is ethylene oxide, and the catalyst sodium hydroxide is added in an amount of 1.5% of the 1,3-propylenediamine. Weigh 0.1 mol (7.4 g) of 1,3-propylenediamine, 10 mol (440 g) of ethylene oxide, and 60 mg of catalyst sodium hydroxide. Add the above-mentioned initiator 1,3-propylenediamine and catalyst into a closed reaction kettle, vacuumize to -0.1MPa, feed 20g of ethylene oxide, raise the temperature to 110°C to initiate the reaction and continue to feed the remaining ethylene oxide Alkanes, keep warm for 3 hours, remove volatile substances under reduced pressure, and obtain a branched polyether polyamine intermediate.

[0059] Add the branched polyetheramine intermediate synthesized above, 0.22mol (20.35g) of epichlorohydrin, 0.0019mol (0.33g) of potassium sulfate, and 201g of solvent water into the reaction kettle, stir evenly, and heat up to 50°C for 2 ho...

Embodiment 3

[0061] For the branched polyether polyamine, the synthesis initiator is 1,2-phenylenediamine, the polymerization monomer is propylene oxide, and the addition amount of catalyst Na is 1.6% of the mass of 1,2-phenylenediamine. Weigh 0.1 mol (10.8 g) of 1,2-phenylenediamine, 22 mol (1276 g) of propylene oxide, and 37 mg of catalyst Na. Add the above-mentioned initiator 1,2-phenylenediamine and the catalyst into a closed reactor, vacuumize to -0.1MPa, feed 20g of propylene oxide, raise the temperature to 130°C to initiate the reaction and continue feeding the remaining propylene oxide, After heat preservation for 6 hours, the volatile substances were removed under reduced pressure to obtain a branched polyether polyamine intermediate.

[0062] Add the branched polyetheramine intermediate synthesized above, 0.24mol (22.2g) of epichlorohydrin, 0.0024mol (0.42g) of potassium sulfate, and 643g of solvent water into the reaction kettle, stir evenly, and heat up to 70°C for 4 hours , t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com