Combined moving type powder feeder

A composite motion and powder feeder technology, applied in metal material coating process, coating and other directions, can solve the problem that the powder feeder is difficult to feed fine powder evenly, avoid filling jam, avoid pulsation, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

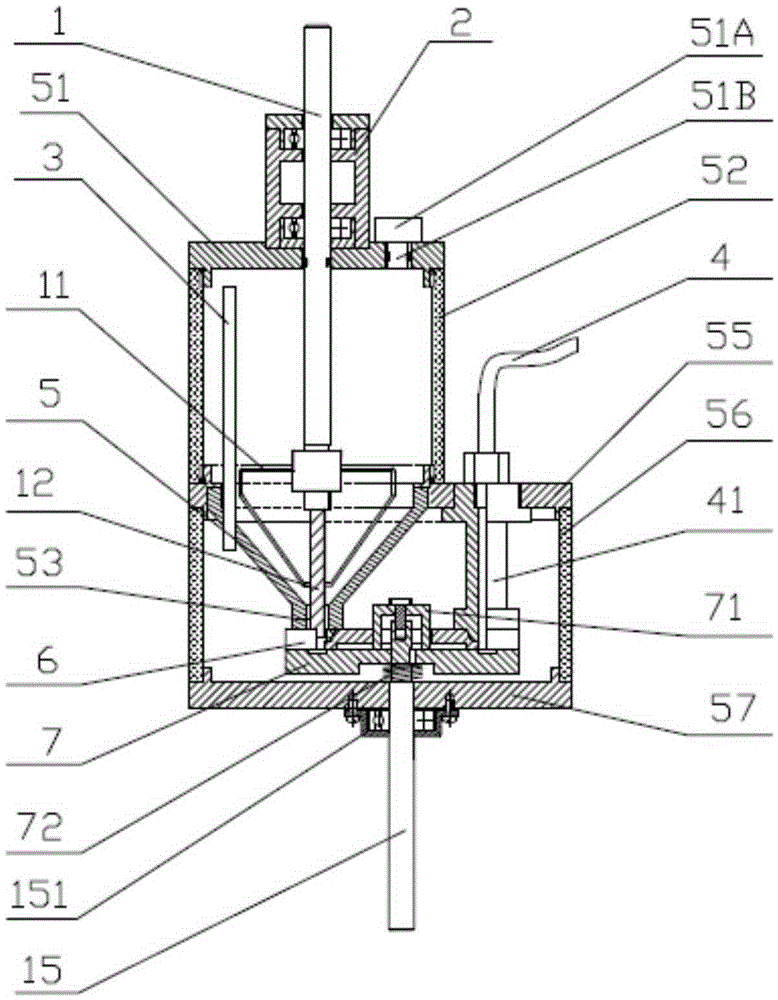

[0050] For example, if the screw impeller 12 rotates the powder delivery volume V per revolution 2 =10πmm 3 , the annular groove 73 of the turntable 7 rotates the powder delivery volume V per revolution 1 =924πmm 3 , η=1.1, then the ratio of the speed of the propulsion shaft 1 to the turntable 7 K=n 2 / n 1 is 101.6. If the rotational speed of the turntable n 1 is 0.7 rev / min, the corresponding propulsion shaft speed n 2 It is 71 revolutions / min; if the bulk specific gravity of the powder is 1.5g / cm 3 , then the feeding amount W of the powder feeder per unit time 2 = 3g / min;

[0051] The stirring rod 11 on the propulsion shaft 1 is used to disperse the powder to prevent the powder from forming an arch structure in the powder hopper, and the helical impeller 12 at the bottom of the propulsion shaft reverses according to the set speed.

[0052] During the powder feeding process, the powder is quantitatively pushed into the powder falling pipe 53 of the powder hopper 5 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com