Building foam and foam wall formed by splicing building foam

A foam and construction technology, applied in the field of construction foam, can solve the problems of unfavorable building ventilation and poor sound absorption effect, and achieve good sound absorption effect, good effect and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

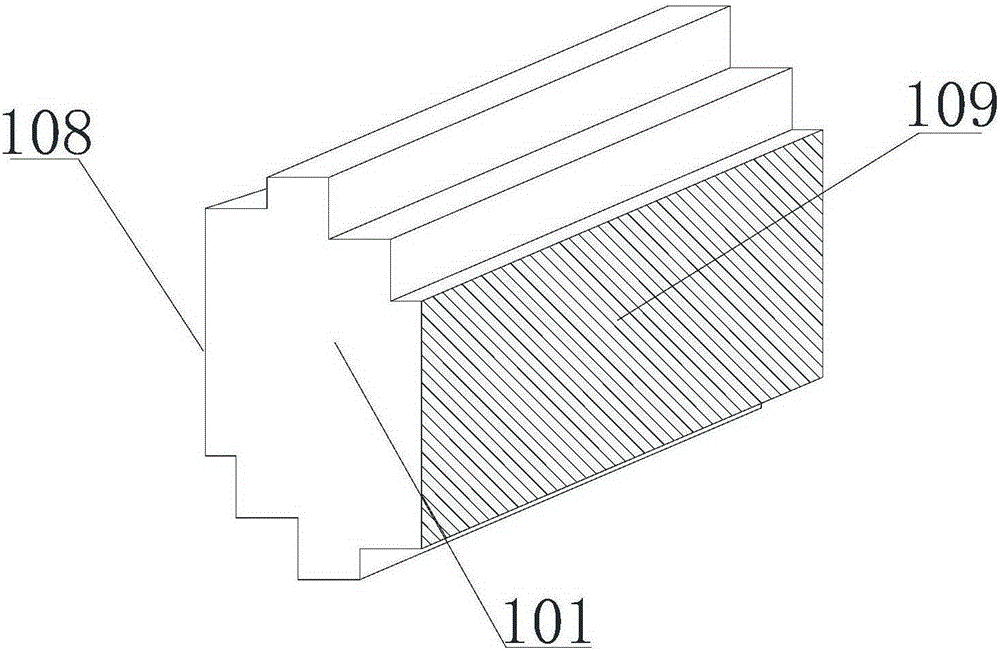

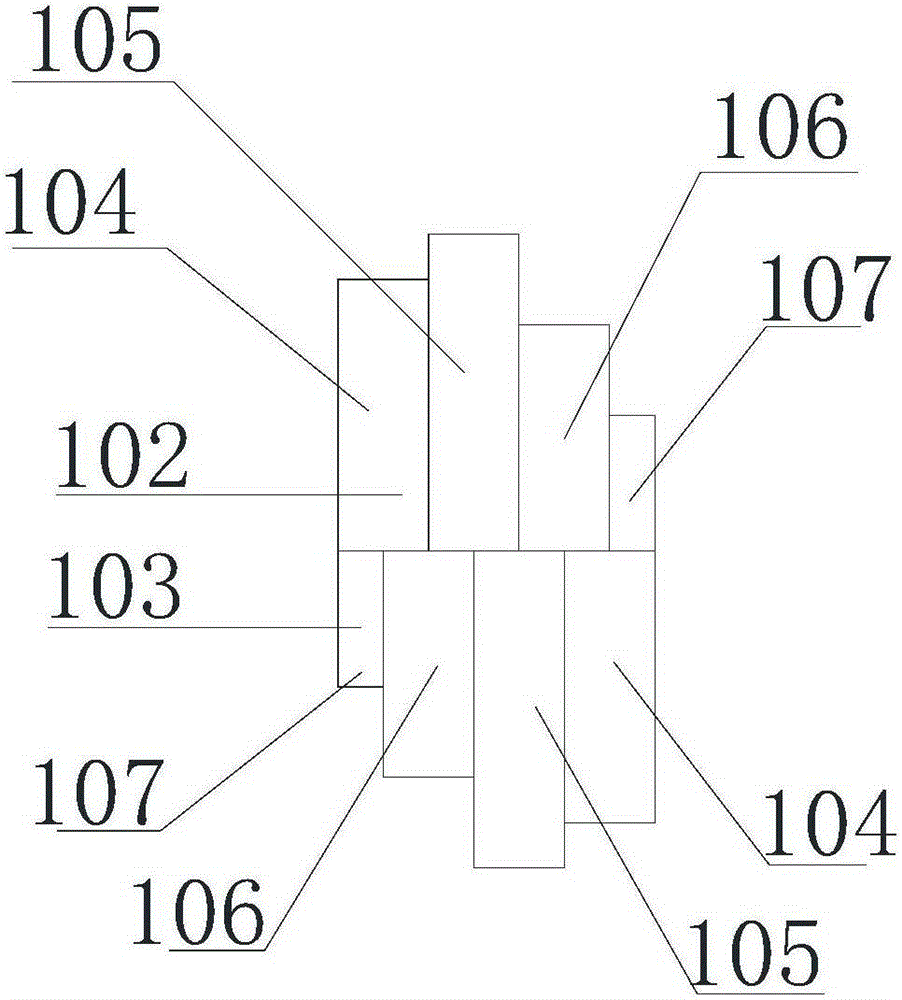

[0037] figure 1 Schematic diagram of the structure of the construction foam provided by Embodiment 1 of the present invention; figure 2 A side view of the construction foam provided in Embodiment 1 of the present invention.

[0038] seefigure 1 and figure 2 , the building foam provided by this embodiment is mainly used to lay on the outer surface of the building, which can protect the building, while ensuring sound absorption inside and outside the building, without affecting the air permeability of the building. The foam includes a foam body 101, two foam bodies 101 are respectively an upper foam body 102 and a lower foam body 103, and the upper foam body 102 is arranged on the lower foam body 103, and the upper foam body 102 and the lower foam body 103 are integrally formed, Both the upper foam body 102 and the lower foam body 103 are composed of four foam boards, namely the first foam board 104 , the second foam board 105 , the third foam board 106 and the fourth foam b...

Embodiment 2

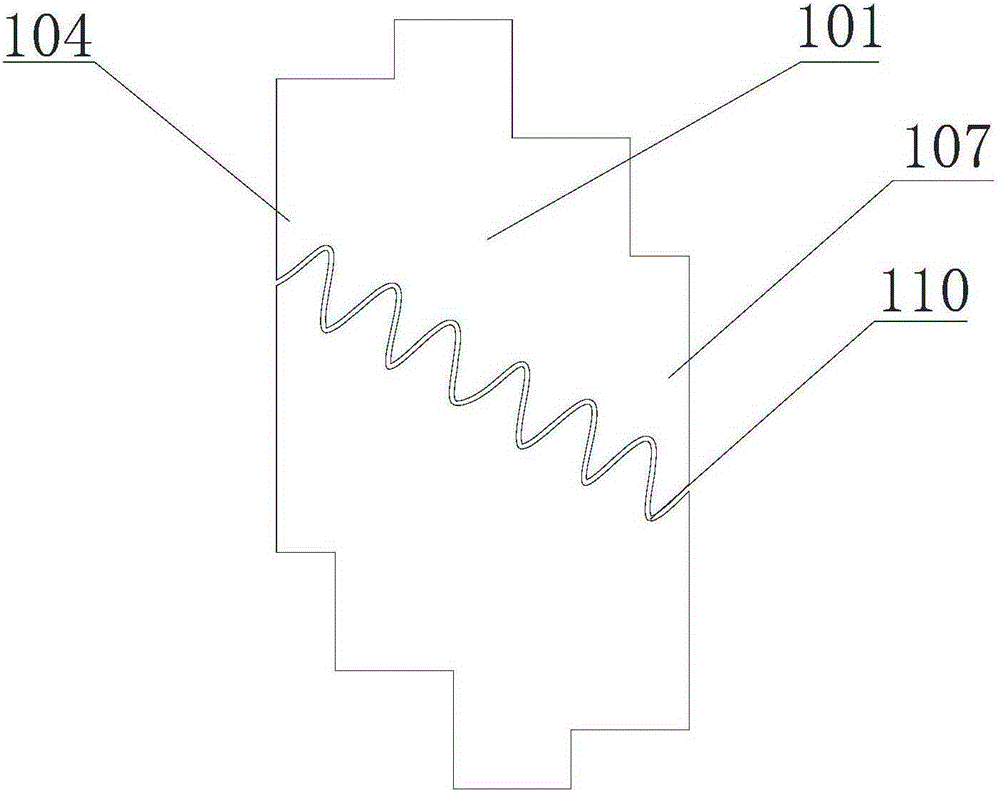

[0044] image 3 It is a structural schematic diagram of the construction foam provided by the second embodiment of the present invention. The building foam provided by this embodiment has the same basic structure, principle and technical effect as that of the first embodiment. For brief description, for the part not mentioned in this embodiment, please refer to the corresponding content in the first embodiment.

[0045] In this implementation, each foam body 101 is provided with a sound-absorbing pipe 110, and the two ends of the sound-absorbing pipe 110 are respectively arranged on the first foam board 104 and the fourth foam board 107, and both ends of the sound-absorbing pipe 110 are provided with openings . By arranging the sound-absorbing pipe 110 in the foam body 101, the foam body 101 can absorb the external noise of the building, reduce the noise, and ensure the comfort in the building. On the four foam boards 107, the sound-absorbing pipe 110 runs through the entire...

Embodiment 3

[0047] This embodiment provides a foam wall formed by building foam splicing, which includes a plurality of foam bodies, and is made by connecting multiple foam bodies in sequence. The foam body is made by connecting multiple foam boards with height differences in sequence. When the foam bodies are spliced together, the four foam bodies can form a through hole due to the height difference of the foam boards.

[0048] Figure 4 The schematic diagram of the splicing structure of the building foam provided by the third embodiment of the present invention; the basic structure, principle and technical effect of the building foam used for splicing the foam wall provided by this embodiment are the same as those of the first embodiment, and are briefly described For parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0049] see Figure 4 , in this embodiment, the splicing method is that the first side 108 of one of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com