Tubing Float Valve and Combined Method of Tubing Blowout Prevention, Gas Lift and Fracturing in Underbalanced Well Completion

An under-balanced, oil-pipe technology, which is used in earth-moving drilling, wellbore/well components, and wellbore/well valve devices, etc., can solve the problems of oil-prevention pipes that cannot be established smoothly, complicated operations, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

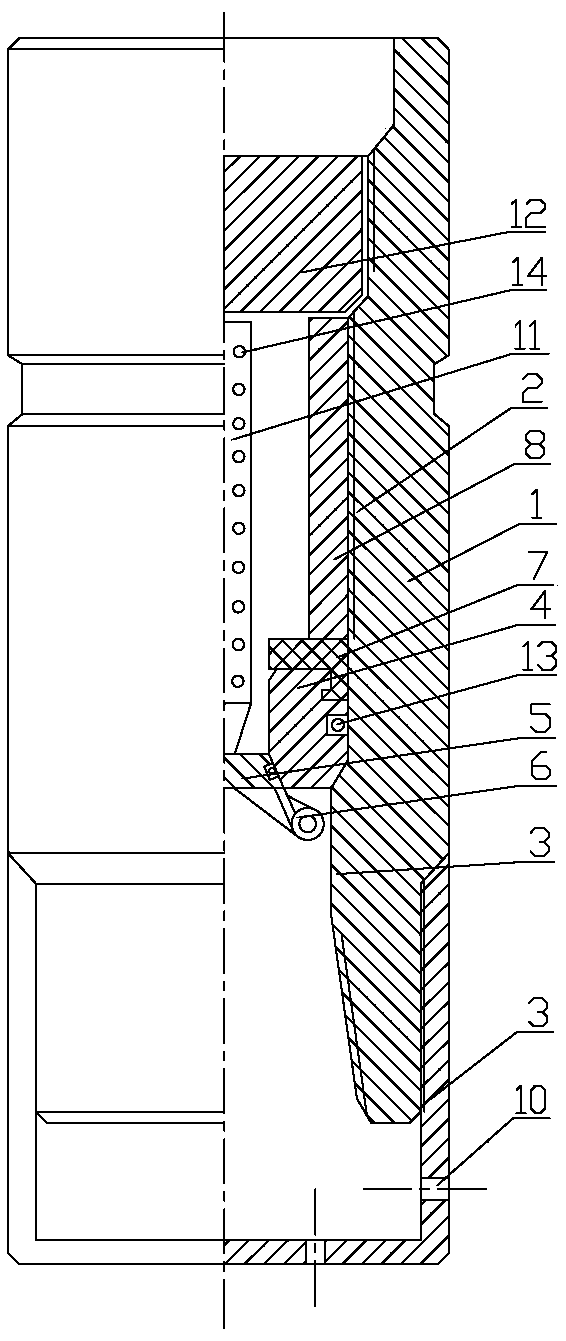

[0019] Embodiment 1, as attached figure 1 As shown, the multifunctional tubing floating hoop includes a body 1, a valve seat 4, a valve 5, a torsion spring 6, a sealing ring 7, a top wire 8 and a fishing basket 9; The reduced upper ring platform 2 and the lower ring platform 3 have a valve seat 4 whose outer diameter matches the inner diameter of the upper ring platform 2 on the upper end surface of the lower ring platform 3. The valve seat 4 is an annular cylinder, and the inner diameter of the valve seat 4 is less than The inner diameter of the lower ring platform 3, the lower inner wall of the valve seat 4 is a conical ring surface with a small upper part and a larger lower part. The end face and the lower end face of the valve 5 are fixedly installed together and the valve 5 is sealed in the lower part of the valve seat 4. On the upper end face of the valve seat 4, there is a seal ring 7 whose outer diameter matches the inner diameter of the upper ring platform 2. A top w...

Embodiment 2

[0022] Embodiment 2, as preferred embodiment 1, as attached figure 1 Shown, the upper end face of lower ring platform 3 is the conical ring surface that is up big and the bottom is small, and the bottom of valve seat 4 is the cone truncated that matches with the conical ring surface of lower ring platform 3 upper surface. When the valve seat 4 is on the upper end surface of the lower ring platform 3, the cone ring surface on the upper end surface of the lower ring platform 3 matches the cone platform at the bottom of the valve seat 4, which can provide better installation stability and sealing.

Embodiment 3

[0023] Embodiment 3, as the preferred embodiment of the above, as attached figure 1 As shown, the upper end surface of the upper ring platform 2 is a conical ring surface with a large top and a small bottom. The lower part of the constant pressure plug 12 is a conical frustum matching the conical ring surface of the upper end surface of the upper ring platform 2. After the constant pressure plug 12 is put in, the conical frustum at the lower part of the constant pressure plug 12 can be better seated on the upper ring The upper end surface of platform 2 provides reliable sealing for perforating and fracturing operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com