Coal mine pressure analysis system

An analysis system and mine pressure technology, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve problems such as low automation, inability to analyze data statistics and early warning, and error-prone, so as to improve efficiency and accuracy, and realize Real-time information monitoring, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

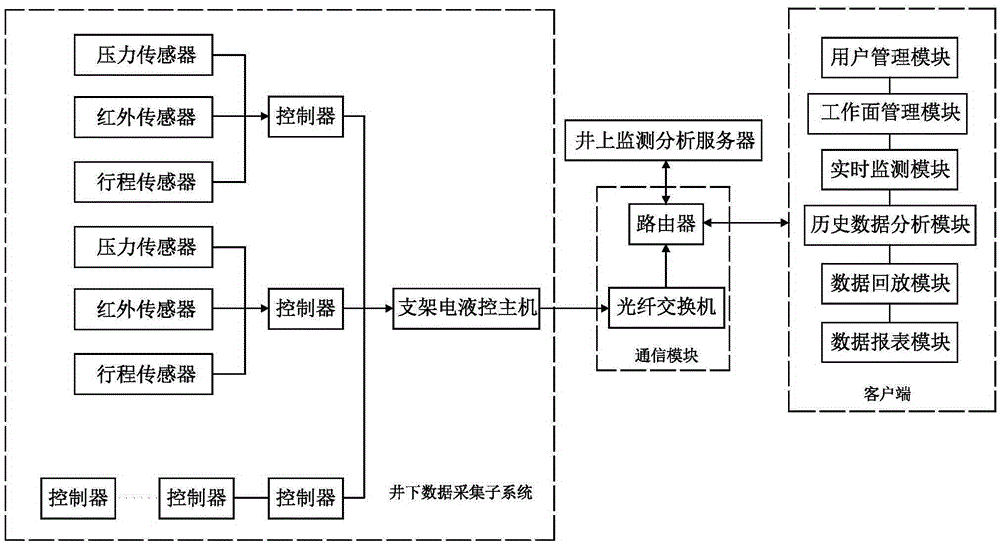

[0024] Such as figure 1 As shown, the structure schematic diagram of the coal mine mine pressure analysis system of the present invention includes an underground data acquisition subsystem, an upper well data processing subsystem, an upper mine mine pressure management subsystem and a communication module, and the upper mine data processing subsystem receives the underground data acquisition subsystem through the communication module. The original data collected by the system is analyzed by the above-ground data processing subsystem and then transmitted to the above-ground mine pressure management subsystem through the communication module. The downhole data acquisition subsystem includes a sensor, a controller, and a bracket electro-hydraulic control host. The sensor, the controller, and the bracket electro-hydraulic control host are arranged underg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com