Multi-cylinder double-level enthalpy-increasing compressor, air conditioner, heat pump water heater and control method

A control method and compressor technology, which is applied in the direction of machines/engines, pumps, pump components, etc., can solve problems such as compressor performance, adverse effects of noise, and excessive fluctuations in refrigerant pressure, so as to avoid design and process defects Difficult to improve the effect of excessive pressure fluctuations and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

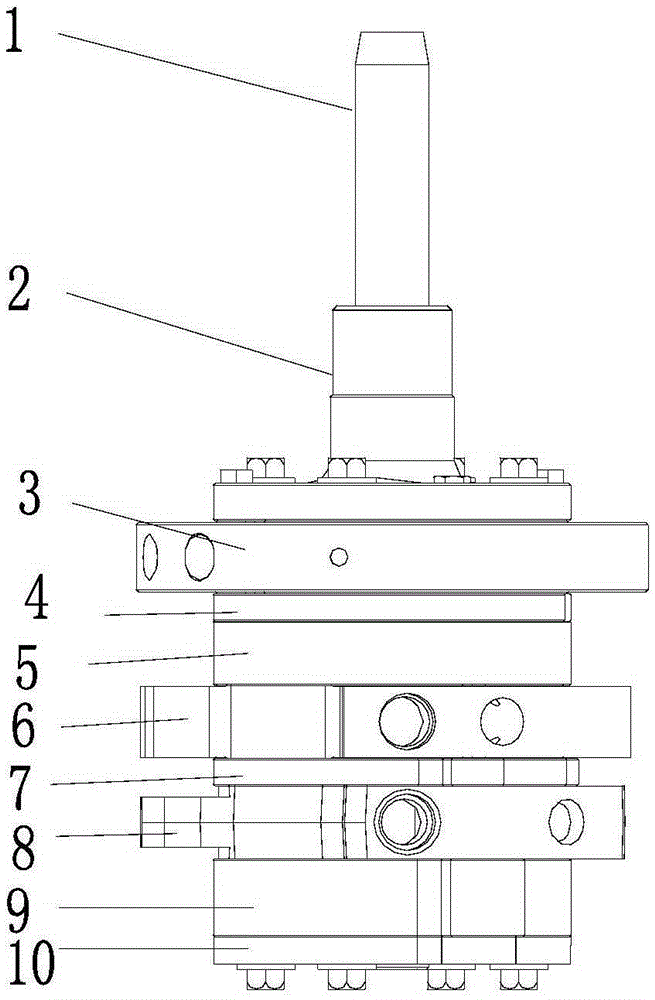

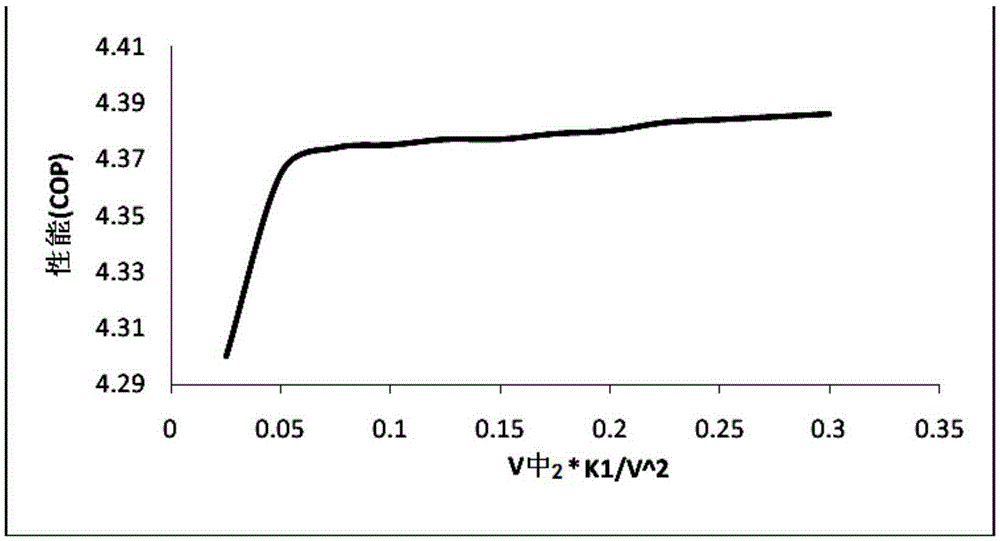

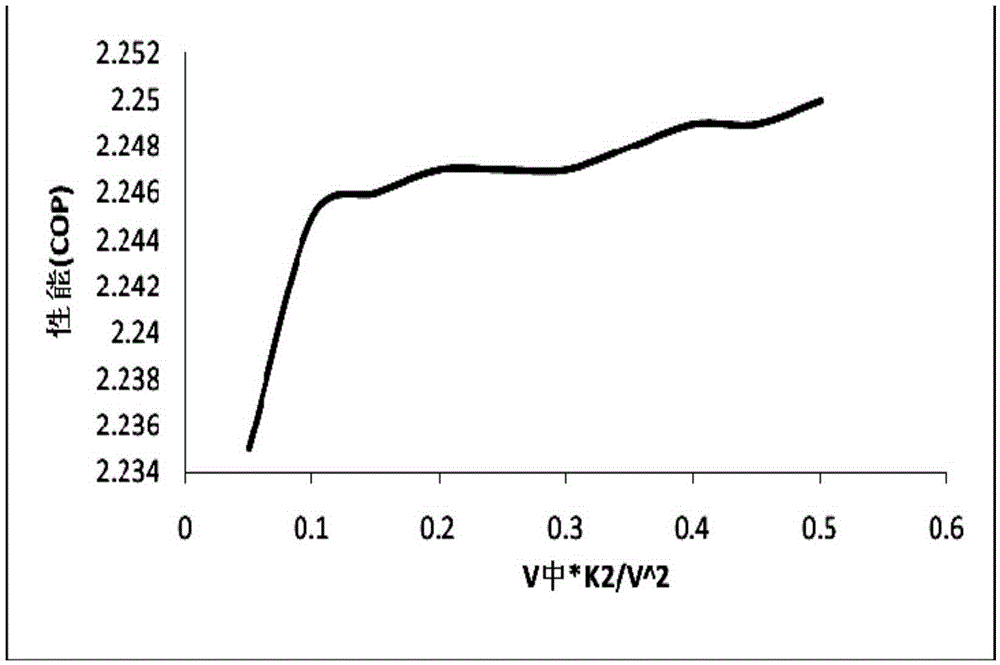

[0028] like figure 1 As shown, the present invention provides a multi-cylinder two-stage enthalpy-increasing compressor, including a lower cover plate, a lower flange, an upper partition and a middle partition, and at least one intermediate chamber volume formed between two of the aforementioned components, The total intermediate cavity volume is the sum of all intermediate cavity volumes, and the total intermediate cavity volume or one of the total intermediate cavity volumes (i.e. any one of the intermediate cavity volume and the total intermediate cavity volume) and The ratio between the product of the volume ratio and the square of the cylinder displacement of the second stage (ie, the aforementioned two-stage) is within the specified ratio range, wherein the volume ratio is the ratio of the second-stage air intake to the first-stage air intake.

[0029] By setting the above relationship of the above parameters, a reasonable volume of the intermediate cavity can be designe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com