High-temperature true triaxial rock testing machine

A true three-axis, experimental machine technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of small size of rock specimens and low heating temperature, and achieve fast heating speed, uniform heating, and high temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, based on the embodiments of the present invention, other embodiments obtained by those of ordinary skill in the art without creative work all belong to this invention. Scope of invention protection.

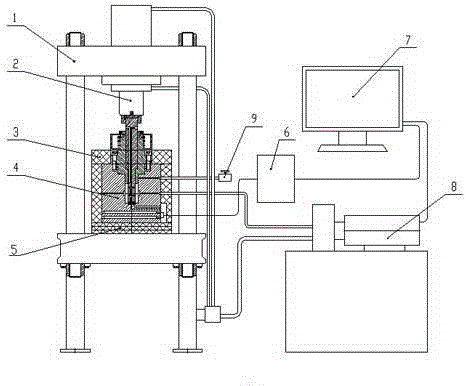

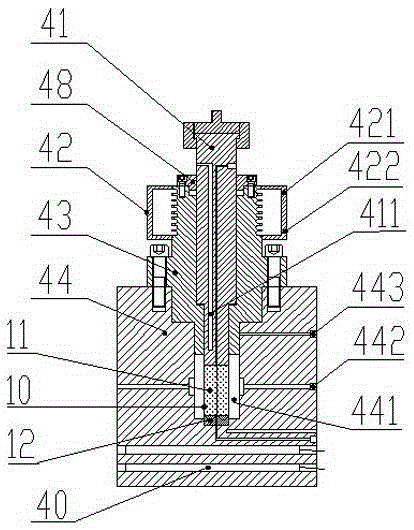

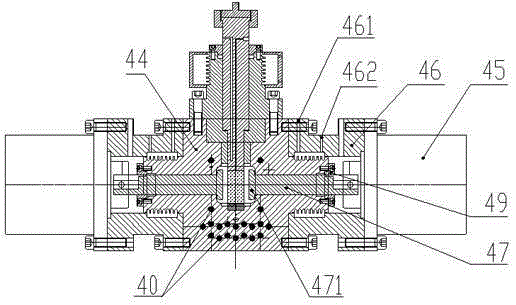

[0019] Such as figure 1 , 2 , 3, a high-temperature true triaxial rock testing machine, including: frame 1, axial loading oil cylinder 2, heat preservation shell 3, host 4, heat shield 5, power switch 6, pressure-temperature-displacement control and Measuring system 7, pressure source 8, the axial loading oil cylinder 2 is installed on the top beam of the frame 1, the host machine 4 is placed on the platform of the frame 1, and is connected with the axial loading oil cylinder 2, and the heat shield 5 is set between the main machine 4 and the platform of the rack 1.

[0020] The main engine 4 includes: an axial loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com