A Photolithography Method Based on Metallic Glass Thin Film Phase Change Material

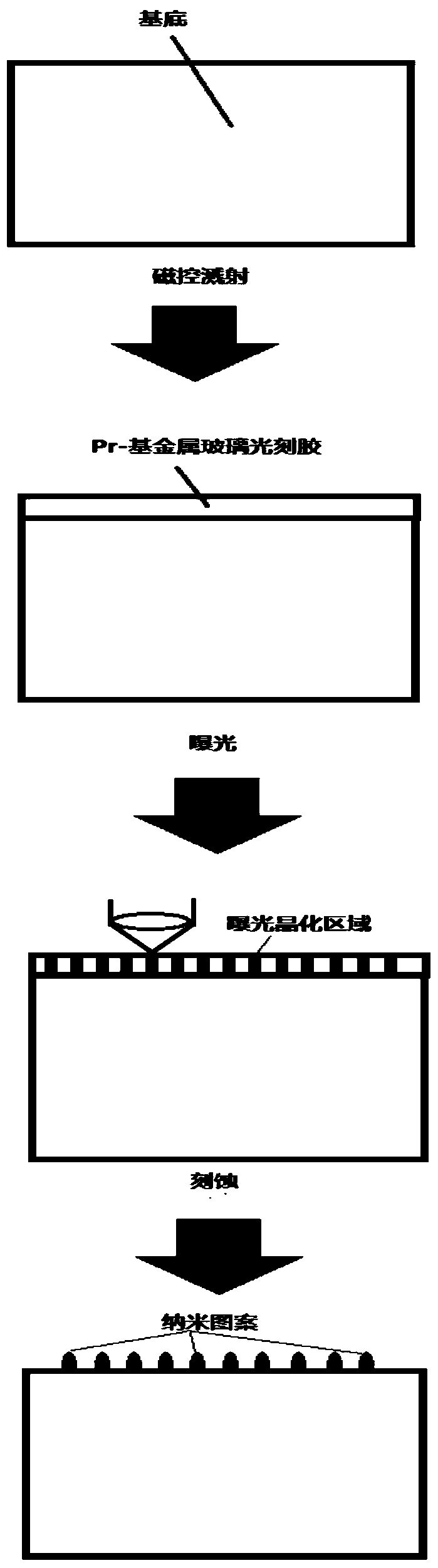

A phase change material and metallic glass technology, applied in optics, opto-mechanical equipment, photo-engraving process of patterned surface, etc., can solve the problems of blurred edges and insufficient steepness in the etching of multilayer films, and achieve high thermal conductivity, high thermal conductivity and high thermal conductivity. The effect of high etch selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A 300nm PrAlNiCu metallic glass film was sputtered on a quartz substrate with a thickness of 1mm by magnetron sputtering. Among them, the specific sputtering parameters are direct current sputtering (DC), the argon pressure used is 0.3pa, the sputtering power is 60W, the target base distance is 120mm, the sputtering time is 15 minutes, and the pre-sputtering is 15 minutes before sputtering.

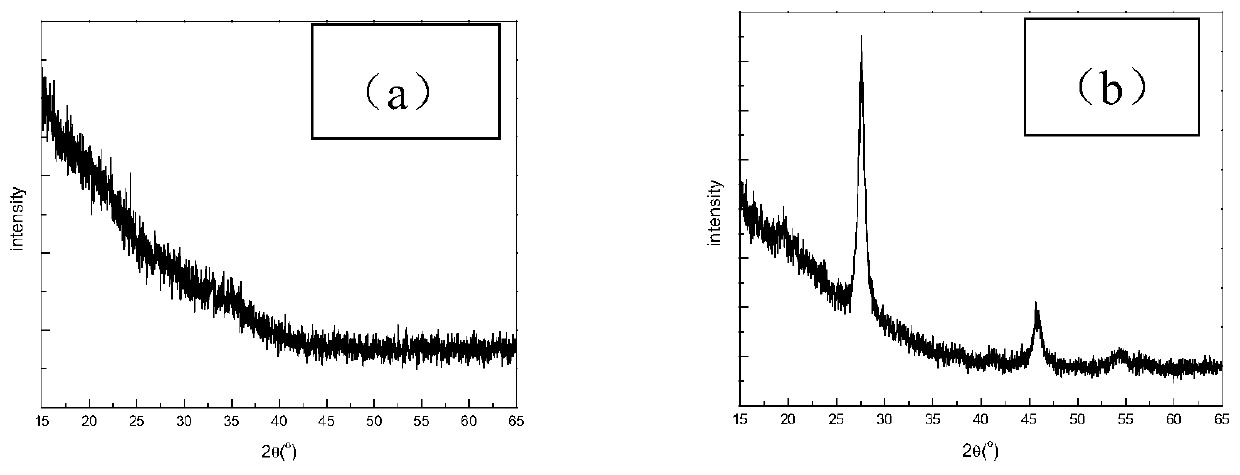

[0040] Using laser to expose, the specific steps are: by fixing the laser light source, placing the sample on the movable motor, importing the step sequence of the nanometer pattern to be obtained into the computer, and using the computer to control the motor step by step, so as to achieve the required Selective exposure direct writing of nanopatterns, figure 2 Shown is the pattern observed with a metallographic microscope after exposure. Such as image 3 As shown, the XRD pattern (a) before exposure is smooth and has no bumps, which is amorphous; the XRD pattern (b) after expos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com