Graphene nanoribbons Fin-FET (Field Effect Transistor) device with controllable channel width and preparation method thereof

A graphene nanoribbon and channel width technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of high cost, low yield, time-consuming, etc., to avoid direct contact, and the method is simple , Easy to remove glue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

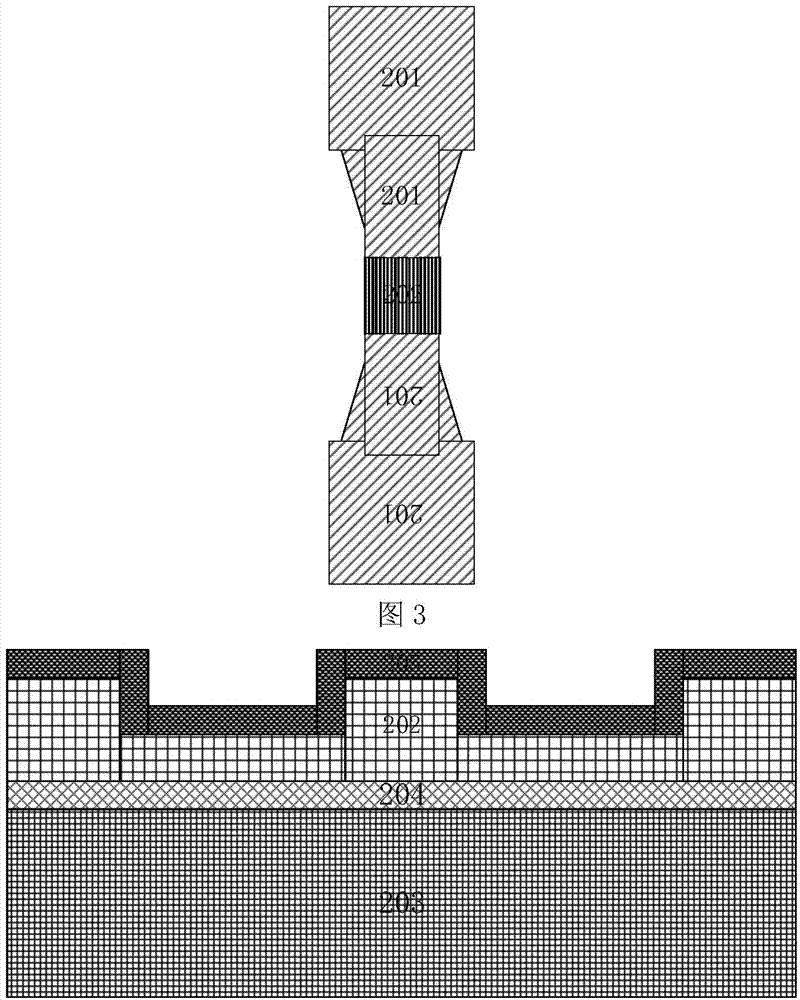

[0027] An exemplary embodiment of the present invention will be described in detail below with reference to the accompanying drawings. In the drawings, for convenience of description, the thicknesses of layers and regions are enlarged or reduced, and the shown sizes do not represent actual sizes. The representations in the referenced figures are schematic, but this should not be considered as limiting the scope of the invention. Also in the following description, the term substrate used may be understood to include the substrate being processed, possibly including other thin film layers prepared thereon.

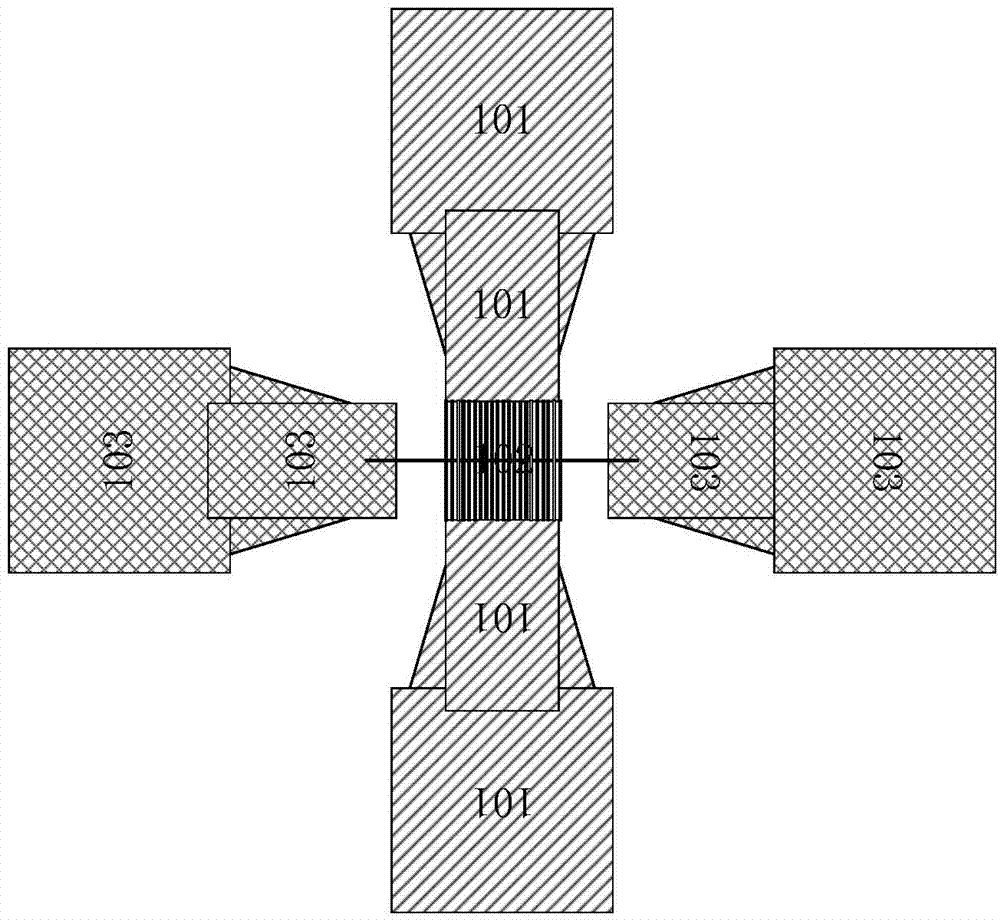

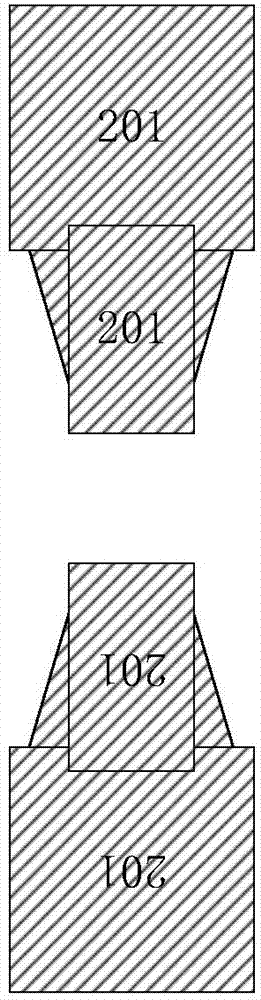

[0028] figure 1 It is a cross-sectional view of an example of a graphene nanoribbon Fin-FET device unit with controllable channel width. like Figure 2-Figure 8 As shown, Ti / Au is selected for the source / drain electrode 201, PVA is selected for the resist 202, located on the silicon / silicon dioxide substrate 203 and the transferred single-layer graphene 204, and Ti / Au is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com