Spring operating mechanism for circuit breaker

An operating mechanism and circuit breaker technology, applied in the field of high-voltage power transmission and transformation, can solve the problems of difficult manufacturing process, low output power, complex structure, etc., and achieve the effect of multiple machine interface modes, low manufacturing cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation

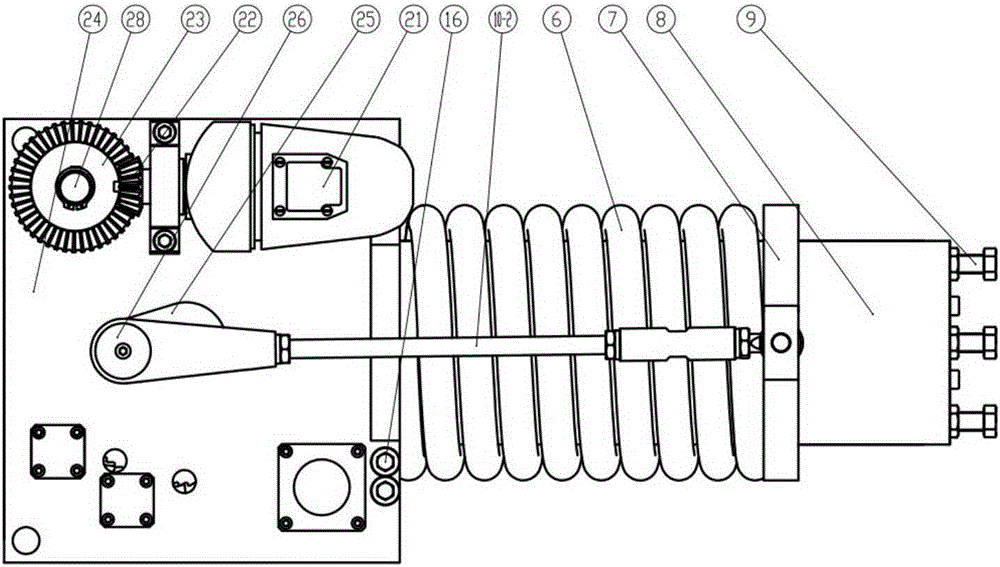

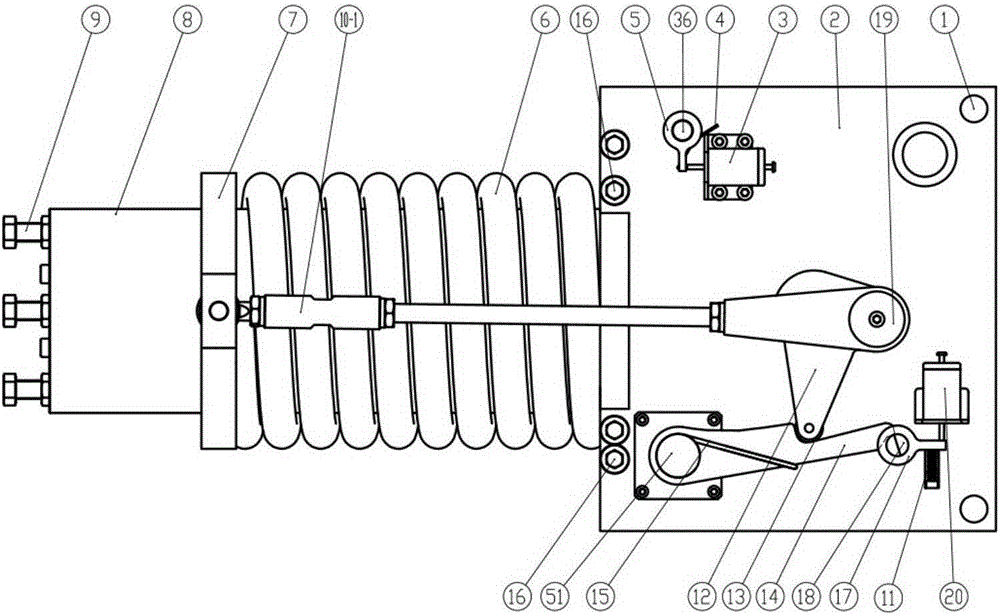

[0018] A spring operating mechanism see figure 2 , image 3 As shown, it mainly includes the transmission actuator formed by the clamping of the left wall plate 2 and the right wall plate 24 arranged in parallel; able agency. The transmission executive mechanism and the energy storage mechanism are arranged in parallel, and are fixedly connected by a spring cylinder flange 50 therebetween. Energy is transmitted between the two through the connecting plate 42 .

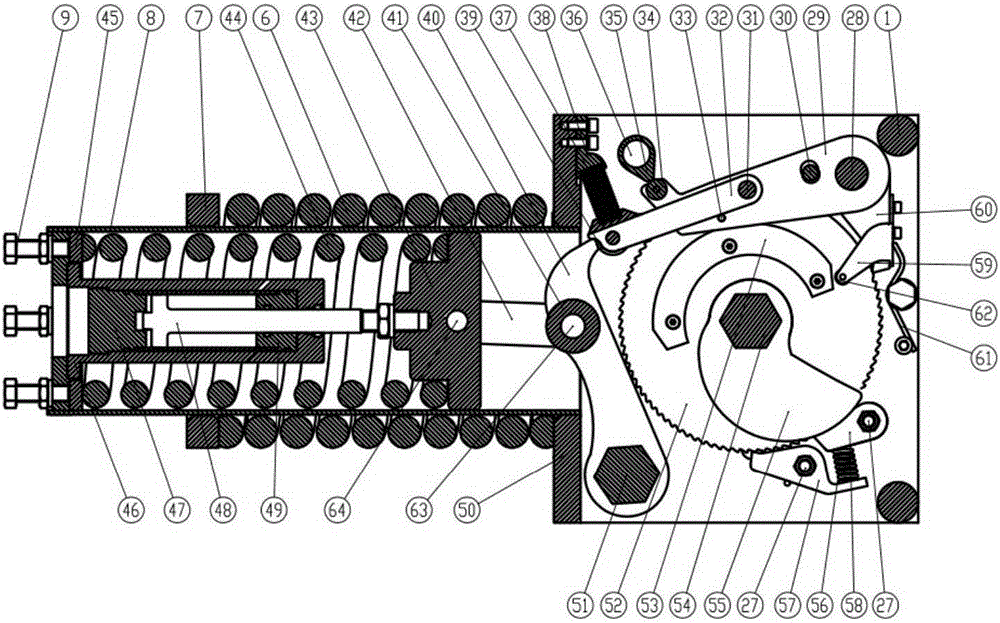

[0019] The transmission actuator described in image 3 , Figure 4 As shown, it is clamped by the left wall plate 2 and the right wall plate 24 arranged in parallel, and the right side in the middle of the two wall plates is fixed with two positioning columns 1 to limit the position, and the left side is limited by the spring tube flange 50 with the fixing bolt 16 fixed.

[0020] Camshaft 54 wears on two wall plates and places the center of the wall plates. Such as image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com