Connector and lamp with same

A connector and connecting part technology, which is applied to contact parts, components of lighting devices, lighting devices, etc., can solve the problems of time and other costs increase, affecting the health of operators, and scalding the hands of operators. Simple process, convenient electrical wiring and product assembly, and strong integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The advantages of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

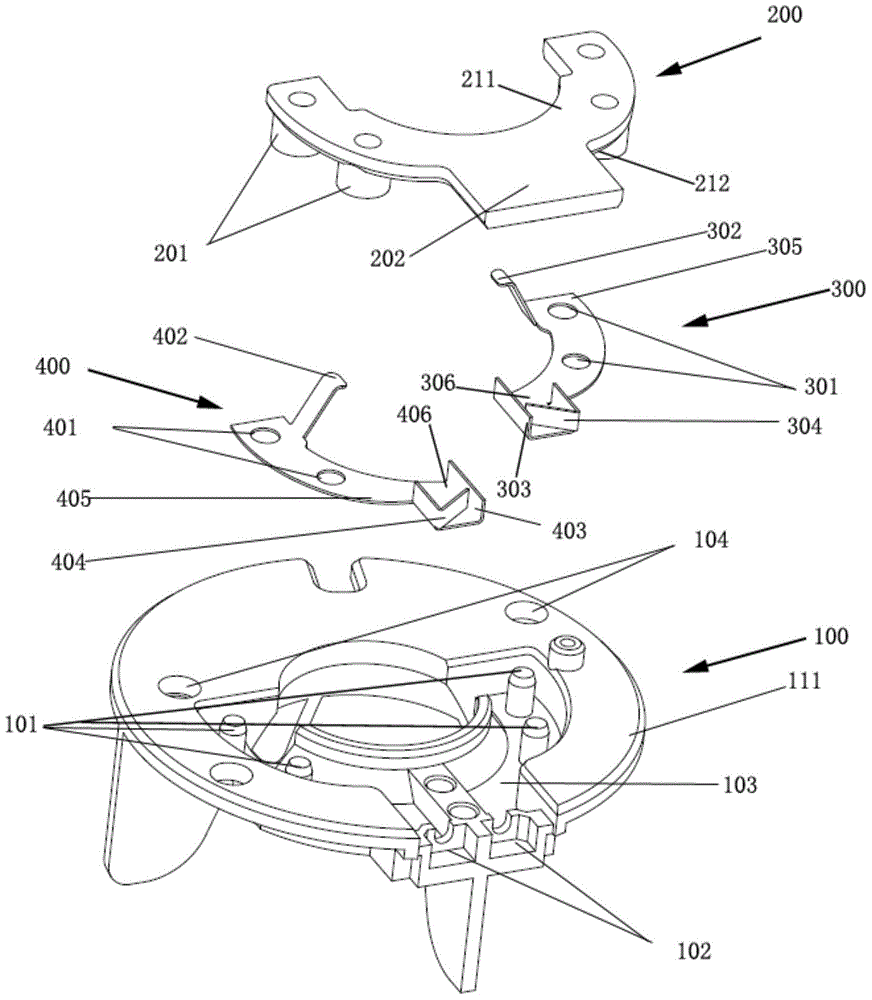

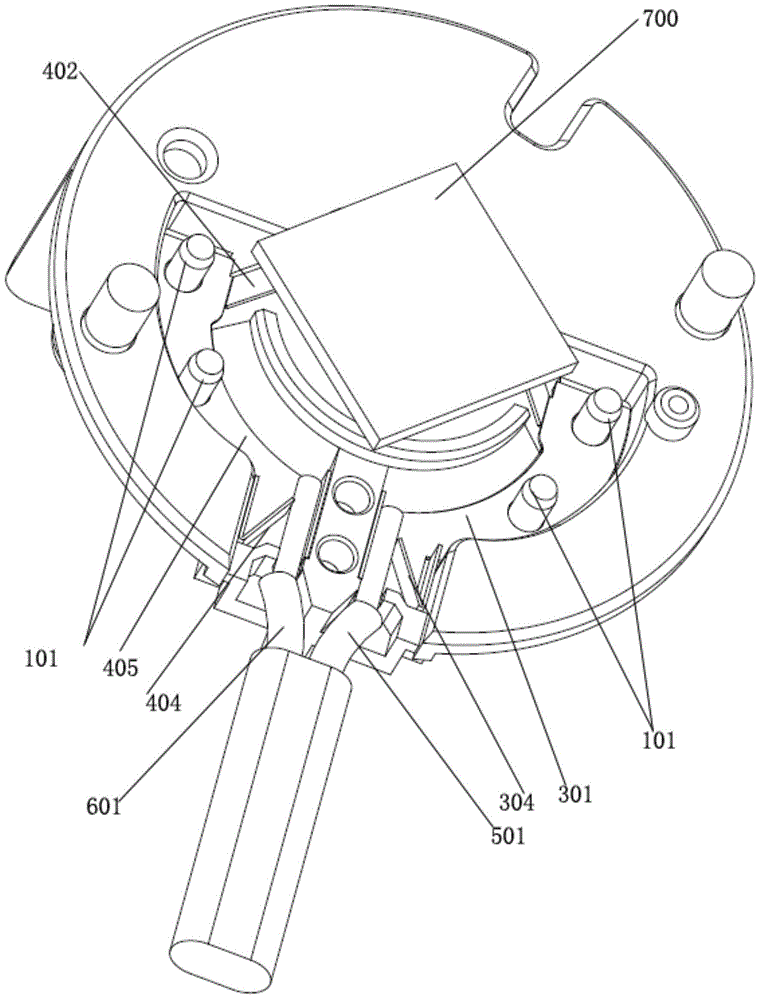

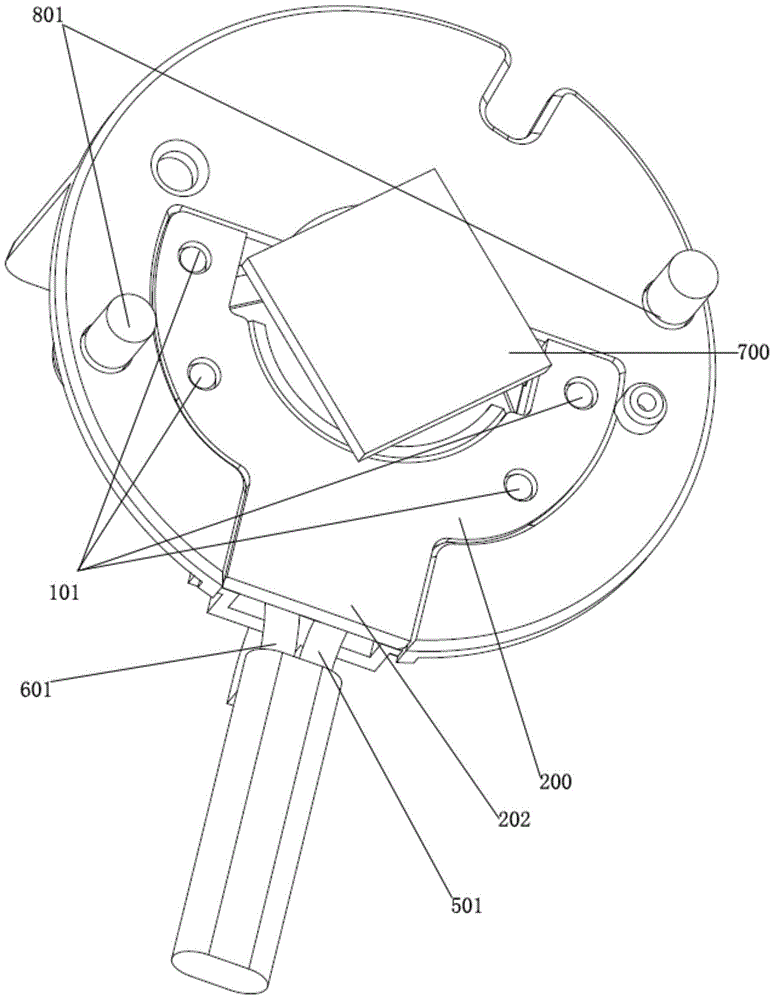

[0038] as attached figure 1 As shown, the connector of the present invention includes a first body 100 and a second body 200 , through which the first conductive terminal 300 and the second conductive terminal 400 can be fixed. And as attached figure 2 As shown, the fixing of the positive power line 501 and the negative power line 601 can also be completed through the first body 100 and the second body 200, and the positive power line 501 and the negative power line 601 (the positive and negative power lines 501, 502 are outsourced The insulating layer (not labeled)) and the light source 700 are electrically connected through the first conductive terminal 300 and the second conductive terminal 400 . Hereinafter, the structures and functions of the first body 100 and the second body 200 in the connector will be described in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com