a wire connector

A technology of wire connectors and connectors, which is applied in the direction of adjusting/maintaining mechanical tension, cable suspension devices, etc., can solve problems such as poor mechanical bearing capacity, wire falling off, and bulky pressing tools, and achieve the ability to increase the bearing tension. The effect of stable and reliable use state and good tension bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

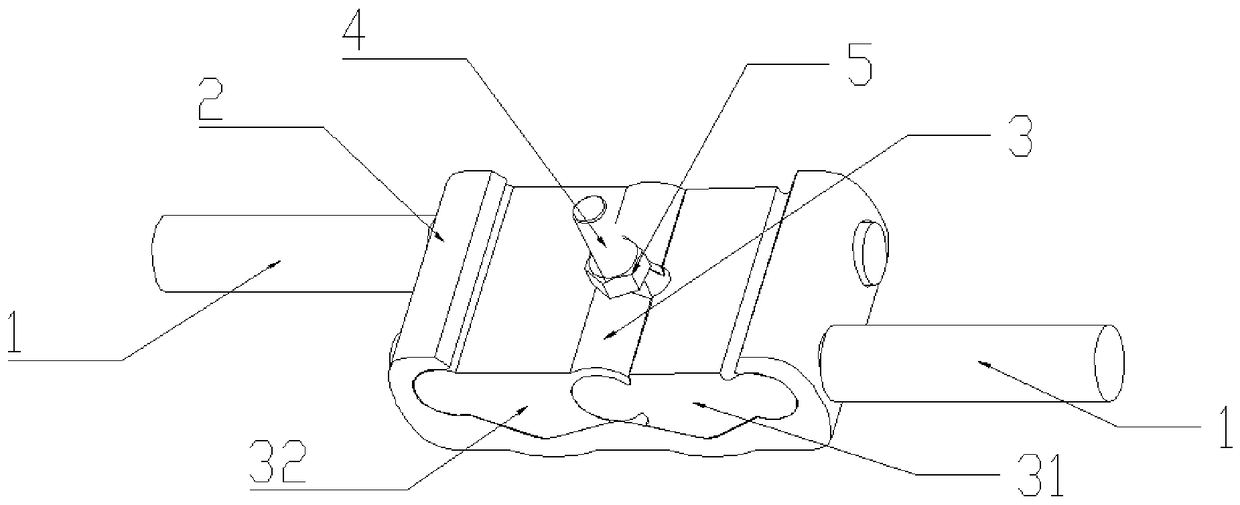

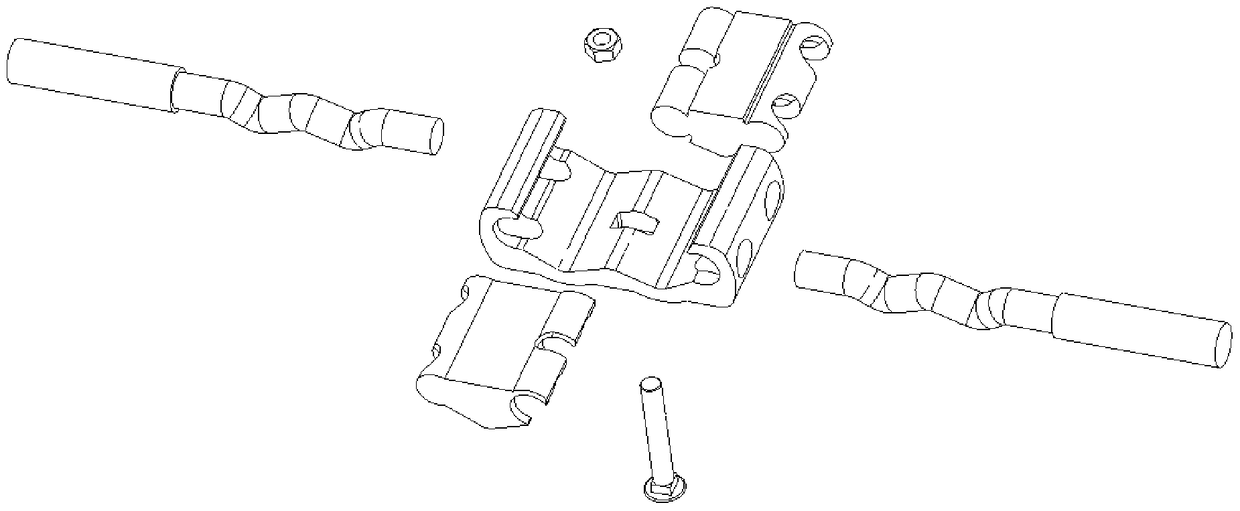

[0063] A wire connector, comprising a connector body 2, a locking block 3 on the connector body 2 and a locking device for detachably connecting the connector body 2 and the locking block 3, one surface of the connector body 2 Correspondingly, one surface of the locking block 3 is provided with a matching concave-convex pressing structure, and at least one of the connector body 2 and the locking block 3 is provided with a function to prevent The limiting structure for the wire to slide laterally. When in use, the wire is set between the concave-convex crimping structure of the connector body 2 and the concave-convex crimping structure of the locking block 3, and is limited by the limiting structure. Under the action of the tightening force, lock and bend the wire to prevent longitudinal slipping.

[0064] The wire connector is provided with at least two connector bodies 2, and each connector body 2 is provided with a locking block 3 and a locking device for detachably connecti...

Embodiment 2

[0075] On the basis of the technical solution of the wire binding clip described in embodiment 1, the following improvements have been further made:

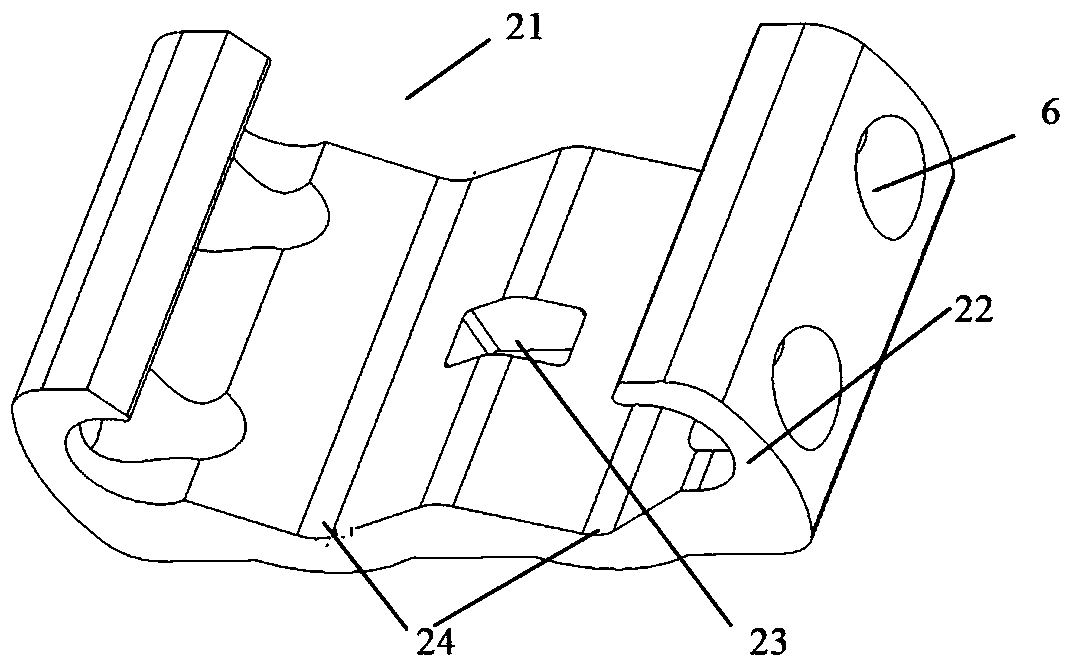

[0076] Such as image 3 As shown, the body groove is a "C-shaped" groove, or the body groove is an "O-shaped" groove. The locking device includes a locking screw 4 .

[0077]The body groove is a "C-shaped" groove, and the connector body 2 and the locking block 3 are respectively provided with a first hole and a second through hole, and the second through hole is located in one of the blocks On or between two blocks, the first through hole and the second through hole are light holes, the locking screw 4 passes through the first through hole and the second through hole to cooperate with a locking nut 5, However, the detachable connection and locking of the connector body 2 and the locking block 3 can be realized, or one of the first through hole and the second through hole is a light hole, and the other through hole can be conne...

Embodiment 3

[0085] On the basis of the technical solution of the wire clamp described in embodiment 1 or embodiment 2, the following improvements have been further made:

[0086] The locking screw 4 is arranged at the center of the clamp body 2, and the installation direction of the locking screw 4 is perpendicular to the wire insertion direction.

[0087] Such as Figures 1 to 7 As shown, the locking block 3 is composed of two blocks, namely a male block 31 and a female block 32, the opposite ends of the male block 31 are convex arc structures, and one end of the female block 32 is a convex arc Type structure, the opposite end of which is a concave arc structure, the arc of the convex arc structure and the concave arc structure is greater than 180 °, the convex arc structure at one end of the male block 31 is hinged with the connector body 2, and the other end The convex arc-shaped structure of the female block 32 is fitted in the concave arc-shaped structure of the female block 32 to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com