High-voltage high-efficiency motor above 3kv high thermal conductivity insulation structure

A high-voltage motor and high thermal conductivity technology, which is applied in the shape/style/structure of winding insulation, magnetic circuit shape/style/structure, electrical components, etc., can solve the problems of high-voltage motors that are difficult to improve efficiency, reduce temperature rise, and have no insulation structure. To achieve the problems of high-efficiency motors, to achieve the effect of a significant drop in motor temperature rise, to overcome poor thermal conductivity, and to reduce the average temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

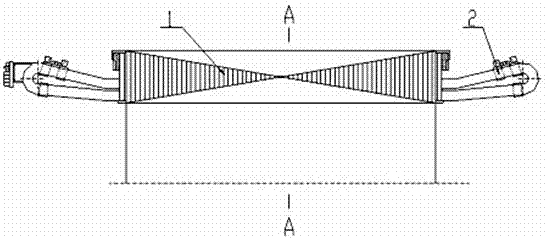

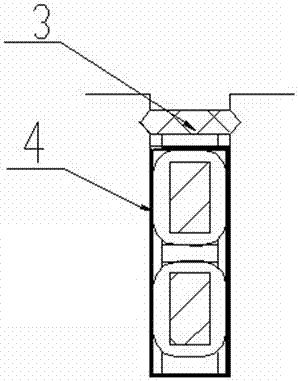

[0026] see figure 1 , figure 2 , the high-voltage high-efficiency motor high thermal conductivity insulation structure above 3kV level of the present invention includes: a stator core 1, a stator coil 2, a slot wedge 3 and a motor insulating paper 4 in a high-voltage motor, wherein the stator core 1 is a high thermal conductivity winding stator The iron core adopts a high thermal conductivity composite insulating glue impregnated insulation structure, and the motor insulating paper 4 adopts a high thermal conductivity composite insulating paper. The insulating paper 4 is a composite pressed product composed of an upper insulating paper, a film and a lower insulating paper. The upper insulating paper and the film and between the lower insulating paper and the film are coated with a high thermal conductivity composite insulating adhesive layer. The upper and lower insulating papers used are high-performance NOMEX paper or DuPont paper or Kunter paper or poly maple. Paper or po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com