Actuator for rendering at least one optical element movable

A technology of optical components and actuators, which is applied in the direction of optical signals, electrical components, transmission devices, etc., can solve the problems affecting the positioning of movable optical components, and cannot eliminate the radial gap and axial gap of the worm, so as to achieve the goal of improving positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

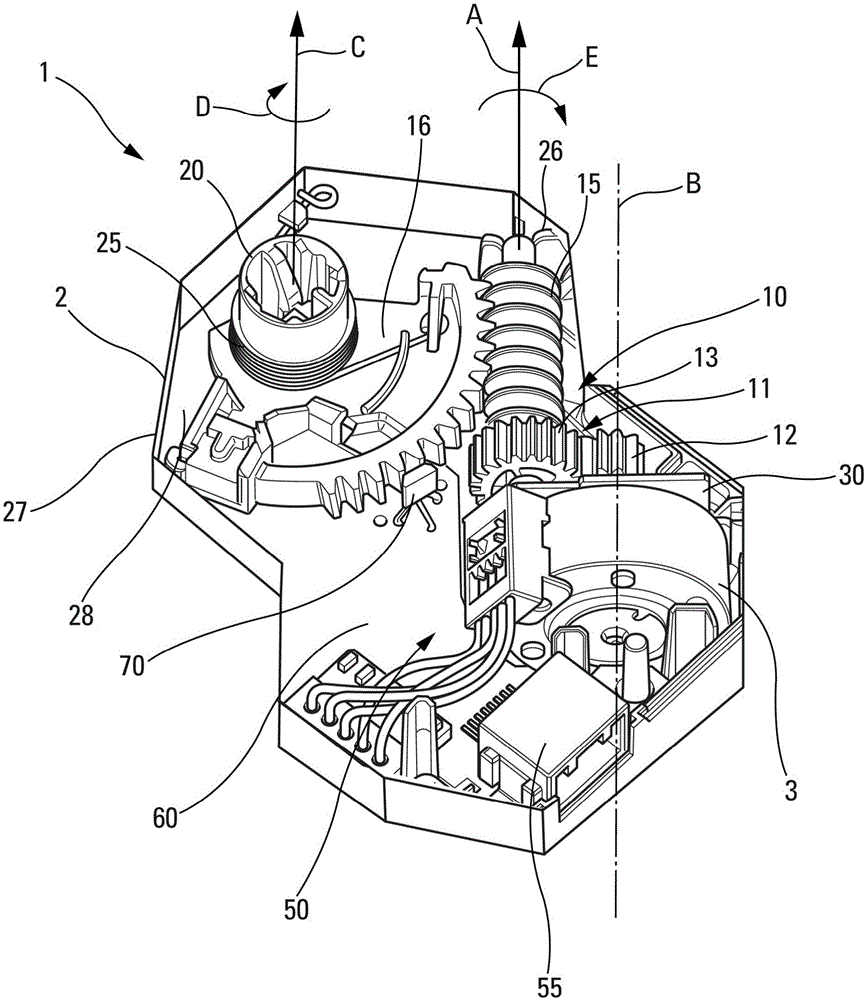

[0027] The present invention involves such as figure 1 Shown is an electric actuator 1 for moving an optical element. This electric actuator 1 comprises housing 2 ( figure 1 Only the lower half of the housing 2 is shown). The housing 2 includes a bottom plate 28 and a peripheral wall 27 .

[0028] The electric actuator 1 also includes an electric motor 3 , a mechanical transmission assembly 10 and a drive device 20 . A mechanical transmission assembly 10 is arranged to transmit the motion of the electric motor 3 to a drive 20 . The drive means 20 is configured to be connected to an optical element (not shown) and to transmit the motion of the motor to the optical element. Here, the motor 3 drives the mechanical transmission assembly 10 via the shaft of the motor arranged to rotate about the axis B. As shown in FIG. Movable optical element means any optical element of a vehicle headlight, in particular a motor vehicle headlight, which is movable for the purpose of changing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com