Integrated motor of energy-saving industrial sewing machine

An industrial sewing machine, sewing machine technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of large occupied space, inconvenient installation, high cost, and achieve the effect of prolonging the service life, simple and compact structure, and good heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

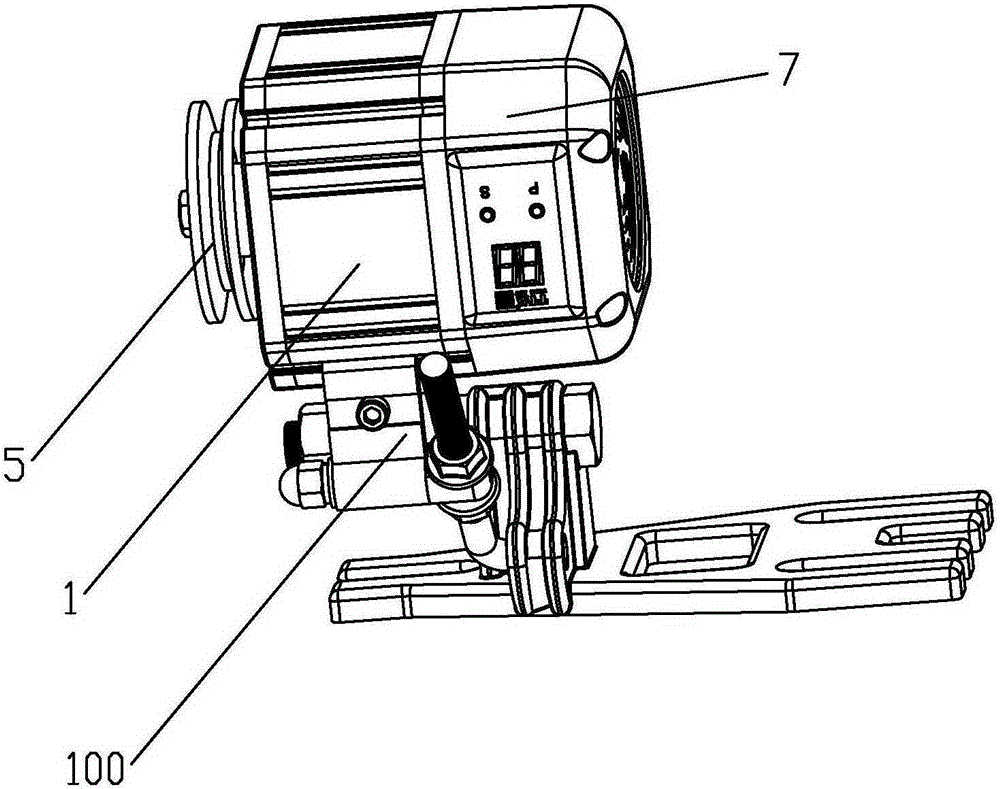

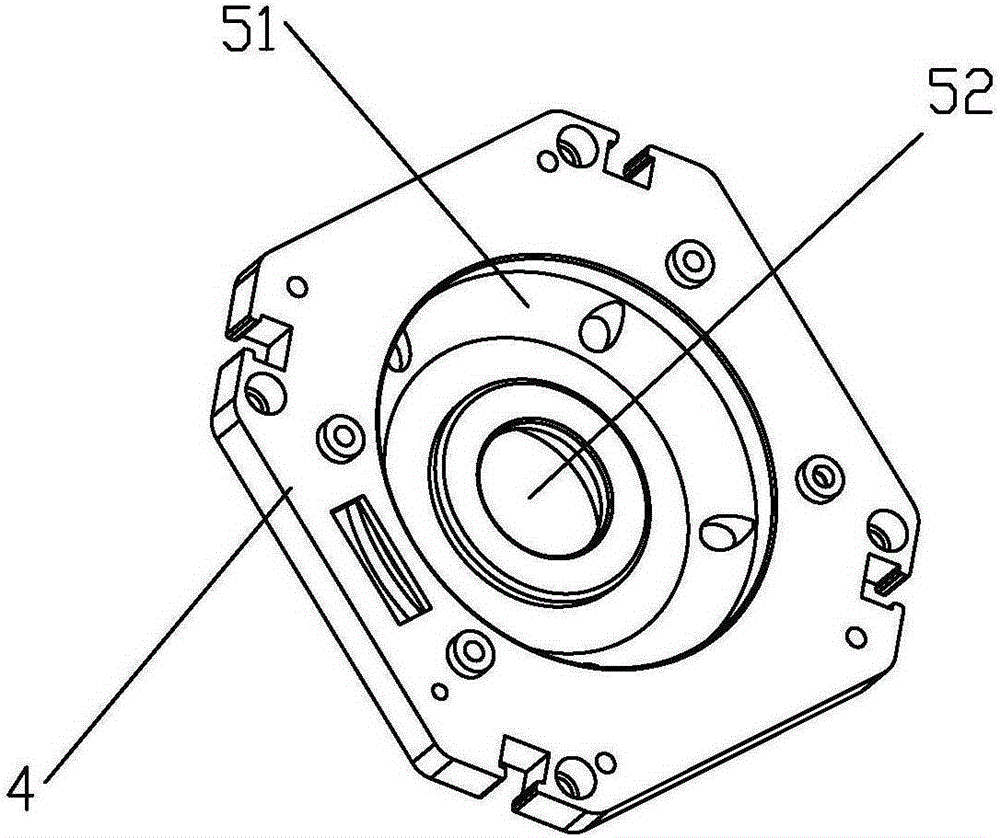

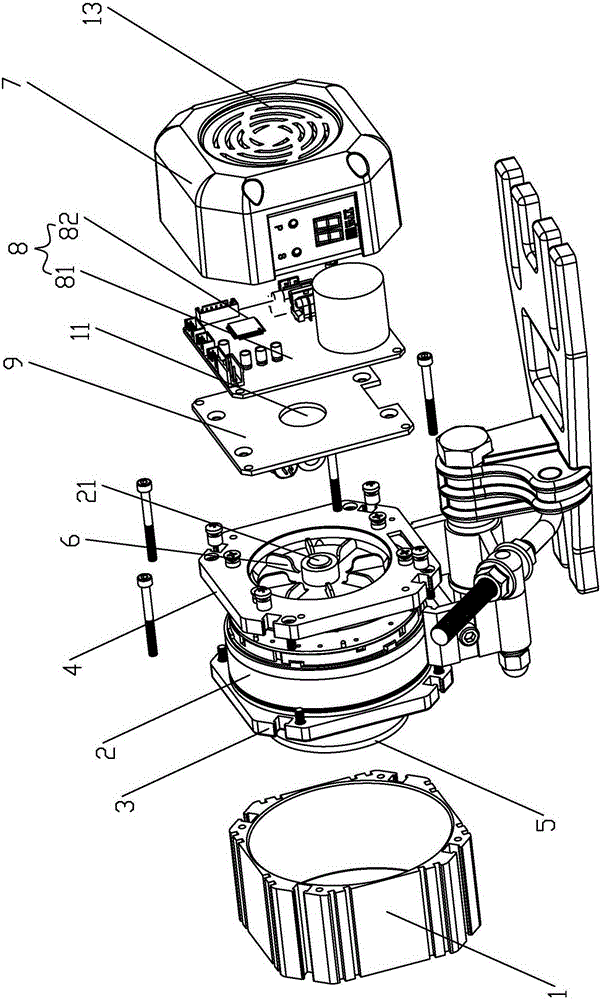

[0027] Such as Figure 1 to Figure 5 As shown, an integrated energy-saving industrial sewing machine motor includes a housing 1 that can be installed on the sewing machine bracket 100, and the housing 1 is provided with a stator and rotor assembly 2, and the stator and rotor assembly 2 includes a rotating shaft 21. The two ends of the shell 1 are respectively provided with a front end cover 3 and a rear end cover 4, and the rotating shaft 21 extends to the outside of the front end cover 3 and the rear end cover 4, and the front end of the rotating shaft 21 is connected with The pulley 5, the rear end cover 4 is provided with a groove 51 recessed to the inside of the housing 1, and the middle part of the groove 51 is provided with a through hole 52 for the rear end of the rotating shaft 21 to protrude. The rear end cover 4 is also connected with a rear housing 7, the rear h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com