Pre-charging and voltage supply systems for dc-ac inverters

A voltage supply, DC-DC technology, applied in the field of pre-charging and voltage supply systems, can solve problems such as overheating and deterioration of pre-charging resistor components, and achieve the effect of reducing surge flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

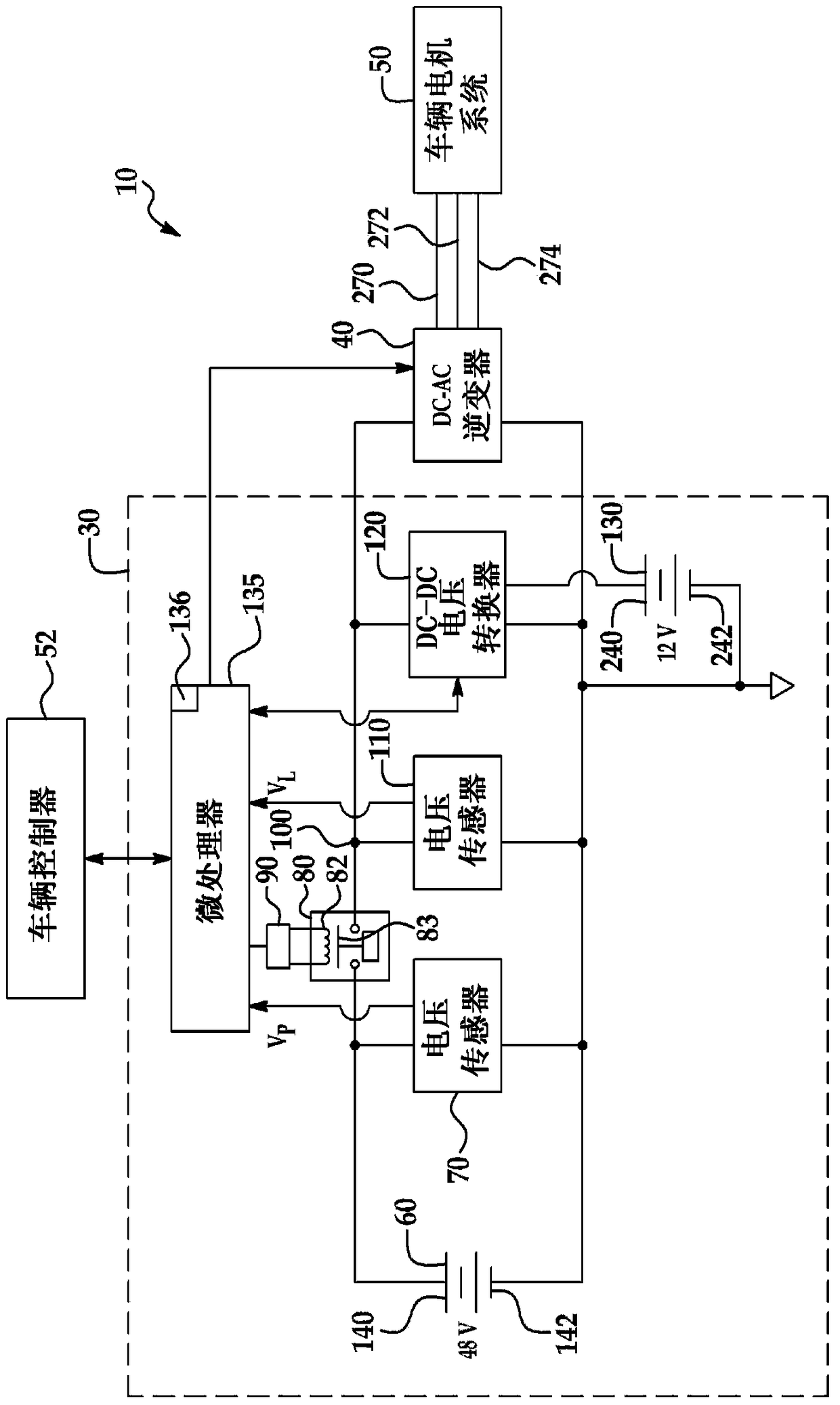

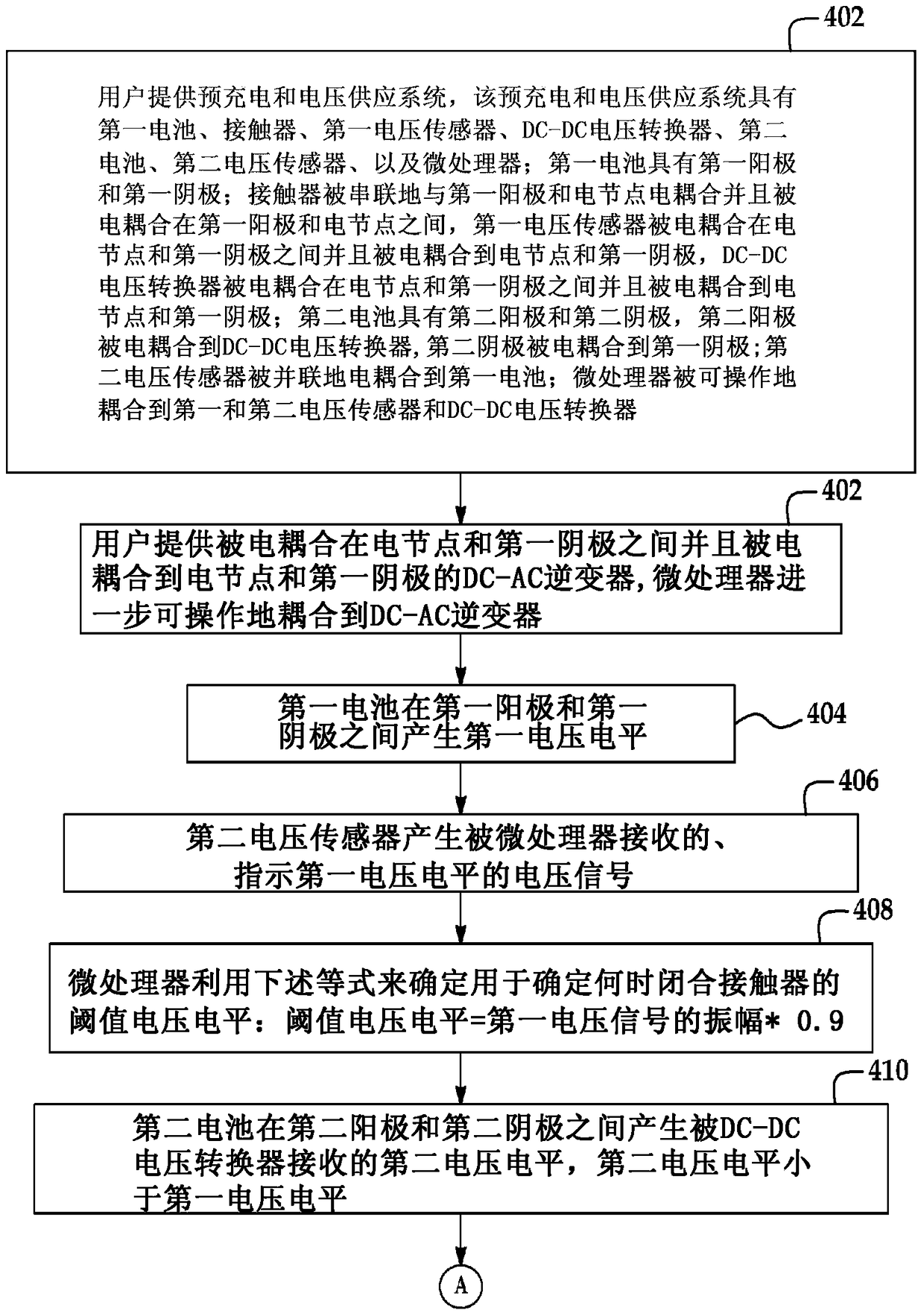

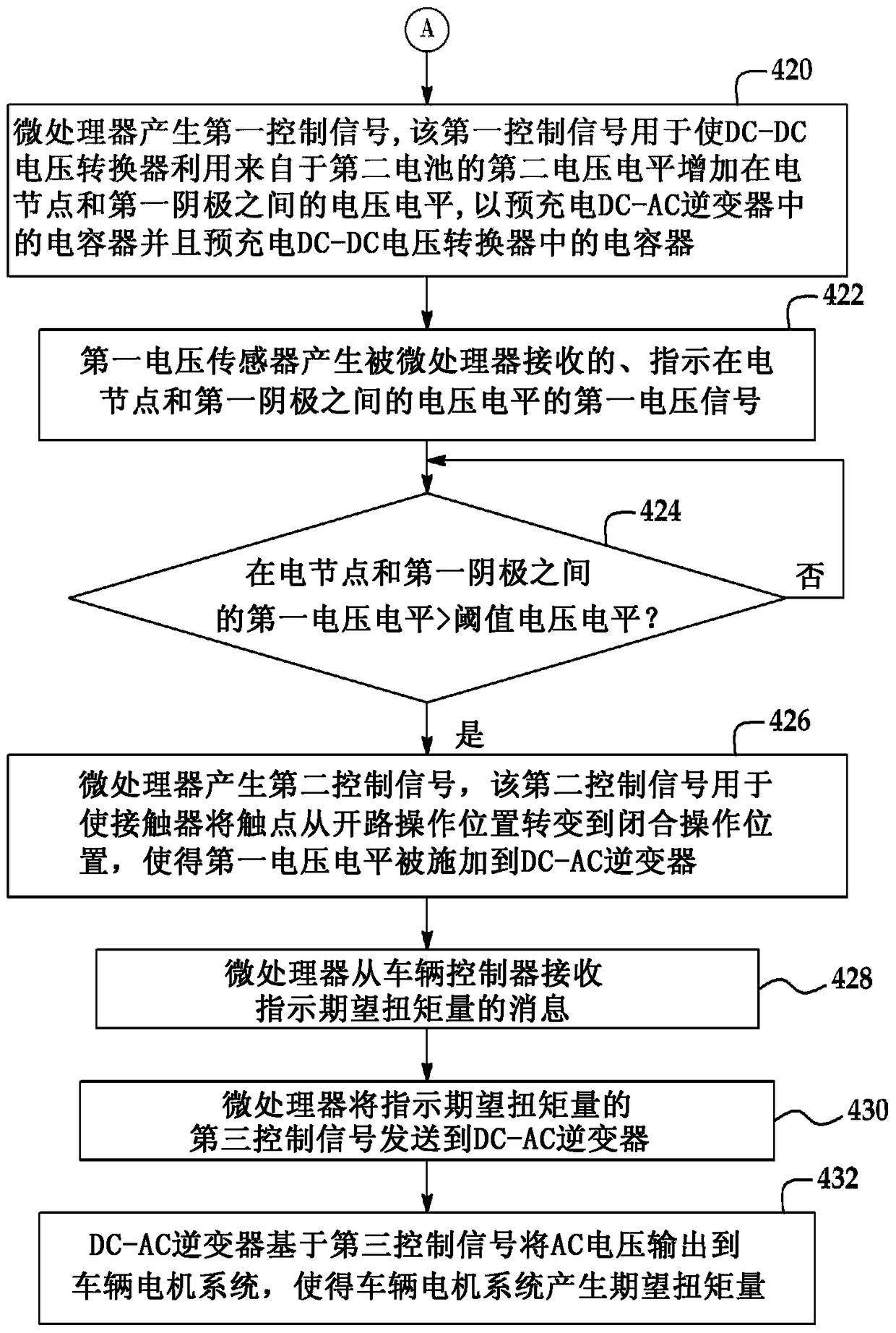

[0021] refer to figure 1 , an electric vehicle 10 having a pre-charging and voltage supply system 30 , a DC-AC inverter 40 , a vehicle motor system 50 , and a vehicle controller 52 according to an exemplary embodiment is illustrated. An advantage of the pre-charging and voltage supply system 30 is that the system 30 utilizes the DC-DC voltage converter 120 and the second battery 130 to pre-charge the capacitors in the DC-AC inverter 40, instead of using additional pre-charging contactors and additional the precharge resistor.

[0022] The pre-charging and voltage supply system 30 is provided to pre-charge at least one capacitor in the DC-AC inverter 40 to limit access to the DC-AC inverter from the first battery 60 when the contactor 80 has a closed operating position. 40 surge flow. After the pre-charge operation, the system 30 provides the operating voltage level from the first battery 60 to the DC-AC inverter 40, and sends a control signal to the DC-AC inverter 40 so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com