A sorting device

A material distribution device and material roller technology, applied in solid separation, chemical instruments and methods, grids, etc., can solve the problems of low degree of mechanization, heavy labor, low efficiency, etc., to reduce labor intensity, improve efficiency, and ensure The effect of screening precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

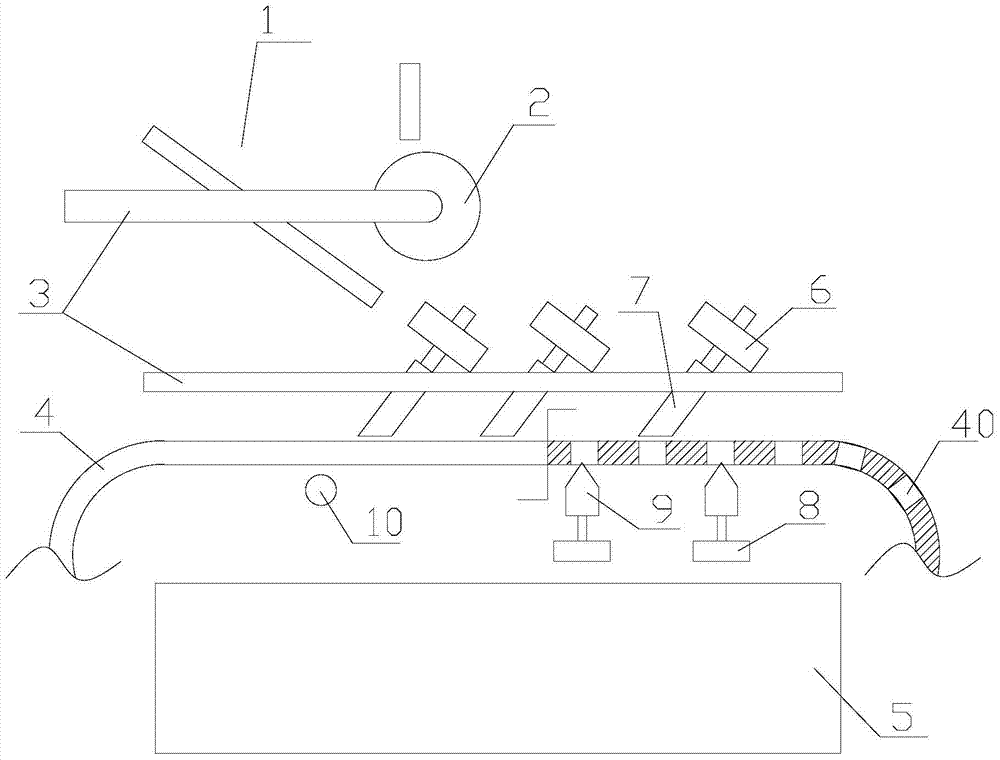

[0015] refer to figure 1 , a kind of distributing device that the present invention proposes, comprises: feeding hopper 1, unloading roller 2, installation frame 3, first transmission belt 4, second transmission belt 5, three installation plates 6, a plurality of avoidance rods 7, two 8 brush bars.

[0016] The feeding hopper 1 is installed on the mounting frame 3, and the unloading roller 2 is installed horizontally at the outlet of the feeding hopper 1 so that it can rotate around the central axis, and the rotating direction of the unloading roller 2 is consistent with the discharging direction of the feeding hopper 1 to avoid blocking material.

[0017] The first transmission belt 4 is horizontally installed below the feed hopper 1, the second transmission belt 5 is horizontally installed below the first transmission belt 4, and the transmission directions of the first transmission belt 4 and the second transmission belt 5 are perpendicular to each other. The first transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com